Double-workpiece table long travel measurement apparatus and use method thereof

A technology of measuring device and workpiece table, which is applied in photoplate-making process exposure devices, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of large Y-direction size of workpiece table system and unconsidered problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

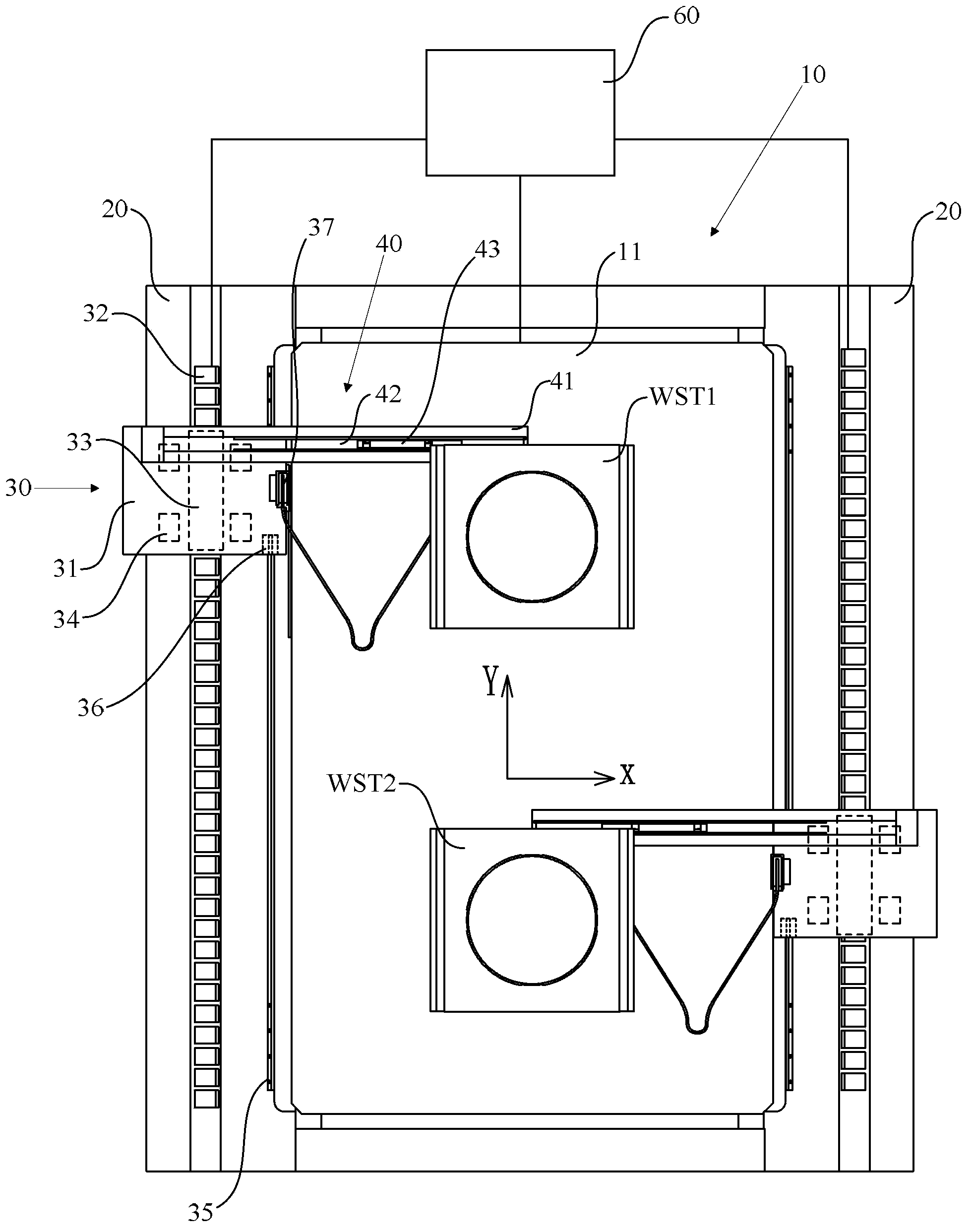

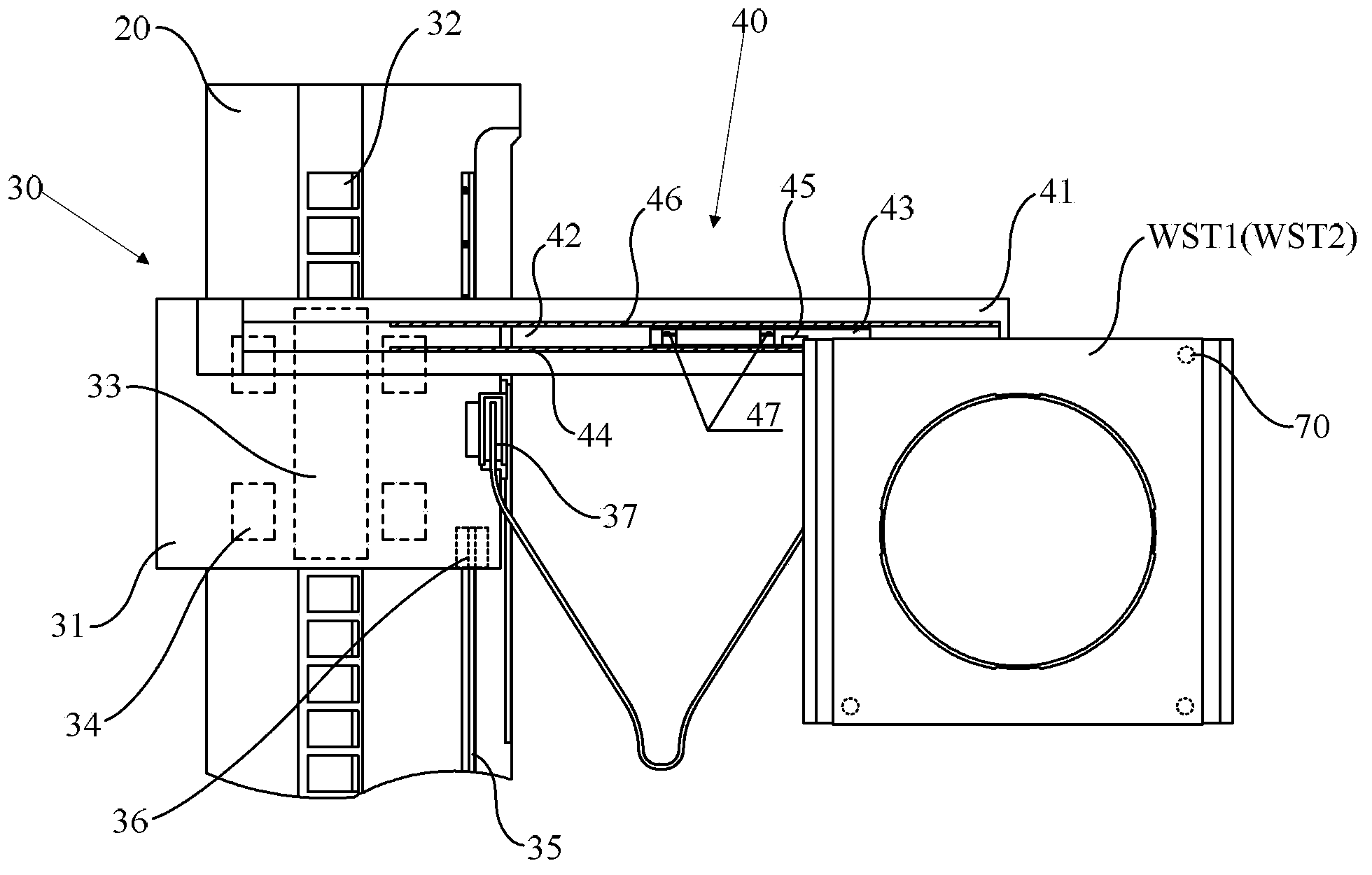

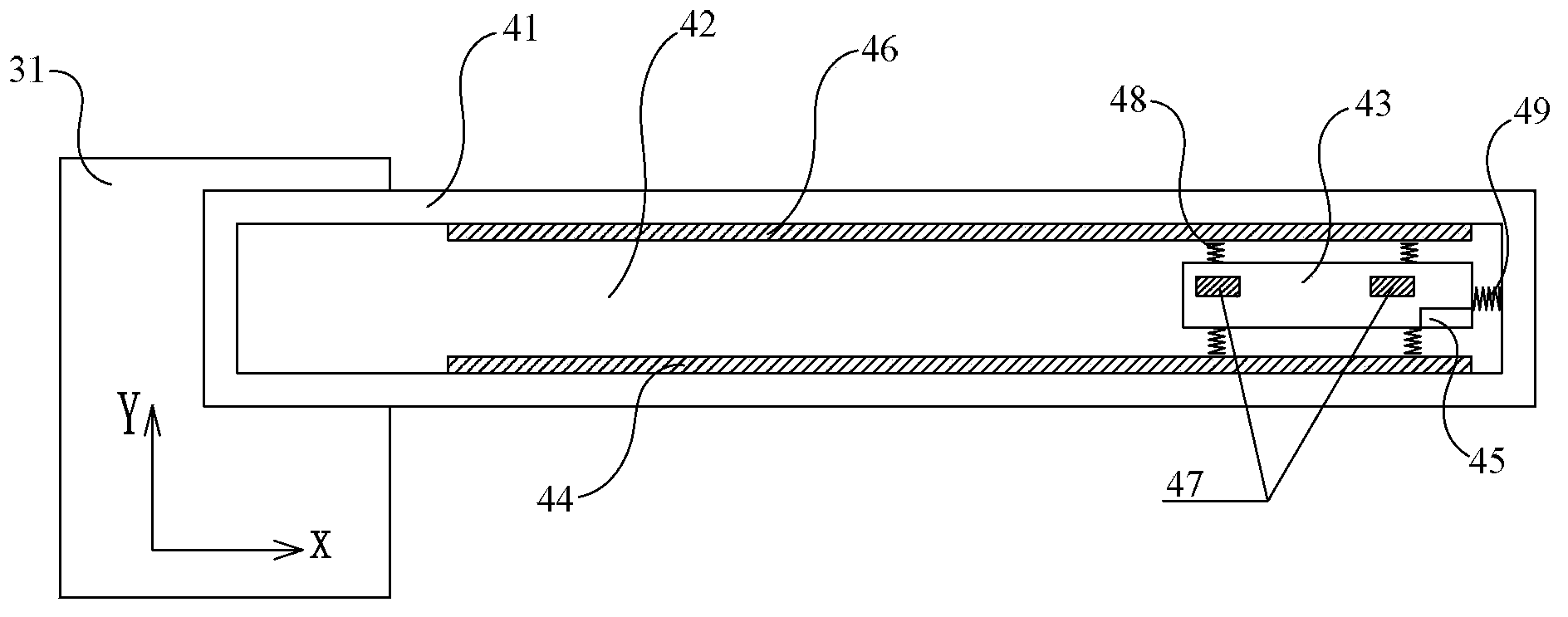

[0046] Please focus on reference Figure 1 to Figure 3 ,Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a double workpiece table long-stroke measuring device, which is used to control the position of the workpiece table (such as a precision workpiece table such as a silicon wafer table or a mask table) in real time for precise photolithography processing Operation, the long stroke measuring device of the double workpiece table includes:

[0047] Coarse-motion planar motor device 10, which is used to move the workpiece tables WST1, WST2 so that the workpiece tables WST1, WST2 move along the X-axis, Y-axis or Z-axis direction on the upper surface of the coarse-motion planar motor device 10, or Rotate along the Rx axis, Ry axis or Rz axis;

[0048] Two guide rails 20, the two guide rails 20 are respectively arranged on both sides of the coarse motion planar motor device 10, and the guide rails 20 are used to place the measuring device us...

Embodiment 2

[0064] The differences between the measuring bracket of the double-workpiece table long-stroke measuring device provided in this embodiment and the measuring bracket described in the first embodiment above are as follows:

[0065] Please focus on reference Figure 4 and Figure 5 ,Such as Figure 4 and Figure 5 As shown, the cross-sectional shape of the sensor bracket 52 is U-shaped, the bracket body 51 is located in the U-shaped groove of the sensor bracket 52, and the X-direction grating ruler 53 and the permanent magnetic steel sheet 55 are all arranged on the The bottom of the bracket body 51, the X-direction grating encoder 54 and the Hall differential sensor 56 are both arranged on the plane in the U-shaped groove of the sensor bracket 52, and the X-direction grating encoder 54 and the Hall differential sensor The sensors 56 are respectively aligned with the X-direction grating encoder 54 and the permanent magnetic steel sheet 55 in the Z direction, and the Y-directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com