Photoisomerization reflecting mirror system

A photoisomerization and mirror technology, applied in the field of aerospace optical remote sensing, can solve the problems of increased weight and volume, increased development cost of remote sensors, and the difficulty of optical system accuracy to meet optical imaging, achieving light weight, saving development costs, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

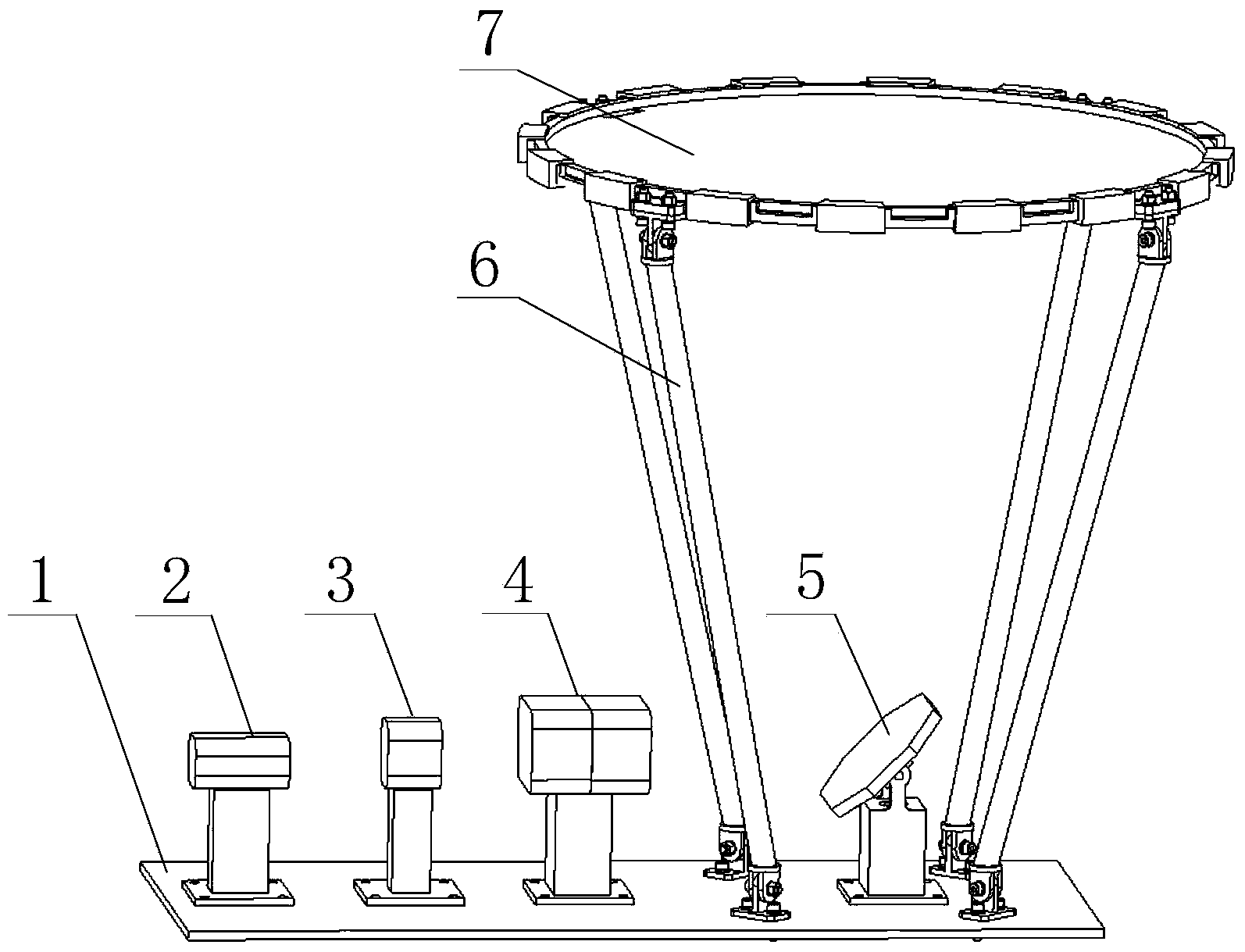

[0016] The invention provides a light-weight photoisomerism reflector system, which is installed in the optical-mechanical system of the remote sensor, used as a reflector for space optical remote sensors, and can be made into a large-diameter reflector, which is light in weight and can control light through polarization The surface shape of the heterogeneous thin film mirror meets the imaging requirements of the optical system.

[0017] The light-duty photoisomerism mirror system adopts a composite film made of a new type of high stability and high uniformity azobenzene derivatives and polyimide film, and utilizes the photoisomerization characteristics of azobenzene derivatives by changing The energy, spot size and polarization direction of the polarized light incident on the mirror surface can be adjusted in real time to change the surface shape of the film mirror.

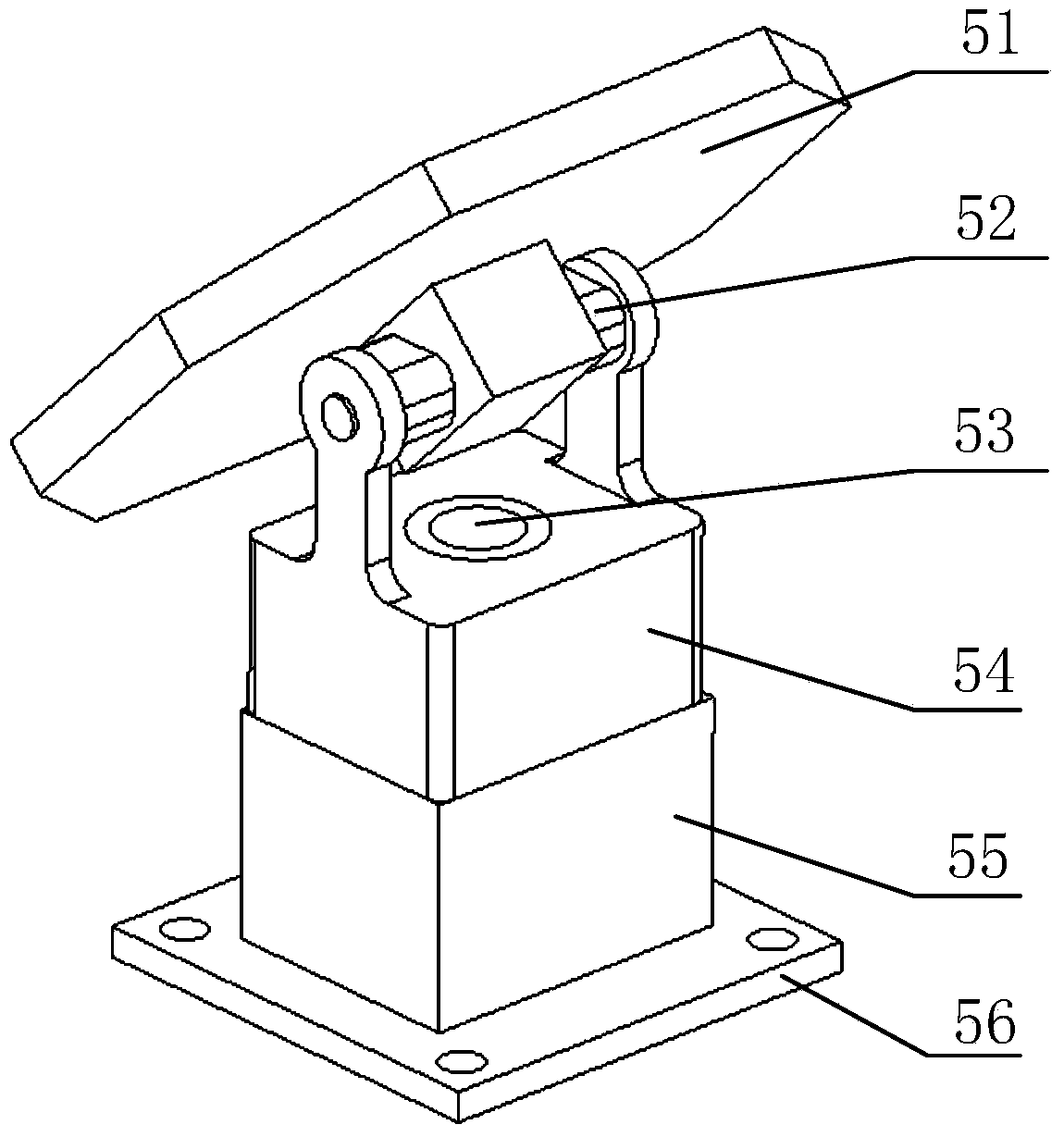

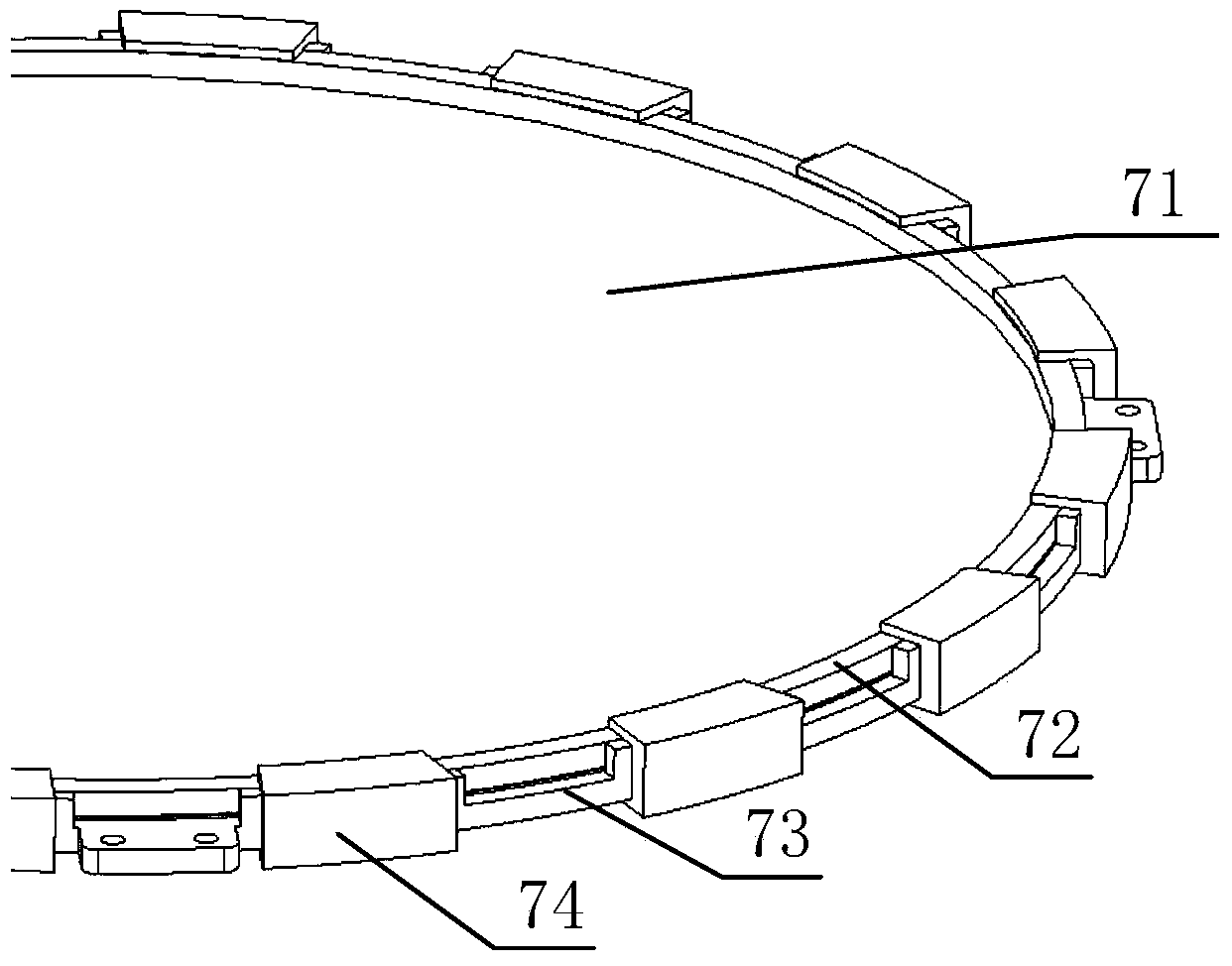

[0018] like figure 1 As shown, the present invention includes a substrate 1 , a laser 2 , a beam expander 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com