Low-attenuation high temperature resistance optical fiber

A technology with high temperature resistance and low attenuation, applied in the direction of cladding optical fiber, multi-layer core/cladding optical fiber, etc., can solve the problems of research on the attenuation performance of non-fiber, and achieve the effect of improving mechanical performance, low attenuation, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

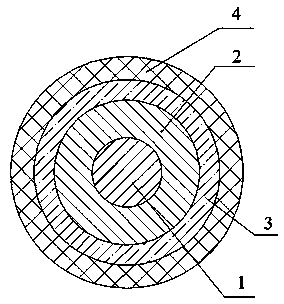

[0020] Core layer, cladding layer and inner and outer coating structure such as figure 1 As shown, a single-mode structure 9 / 125 μm quartz optical fiber is produced, and the inner and outer coatings are respectively modified silicone rubber coating layer and polyimide coating layer, wherein the modified silicone rubber coating is organic silicon Modified silicone rubber OF-182 (purchased from Japan Shin-Etsu Coatings Co., Ltd.), after curing, its elastic modulus is 2.0 MPa, and the working environment temperature range is -70~280 °C; the polyimide coating described is ZKPI- 306H polyimide coating is a high-purity polyimide precursor-polyamic acid solution, which is directly converted into a polyimide film after thermal curing, and the tensile strength after curing is greater than or equal to 150MPa. The elastic modulus is greater than or equal to 3.0GPa, the glass transition temperature is greater than or equal to 400°C, the outer diameter of the inner coating is 165μm, the o...

Embodiment 2

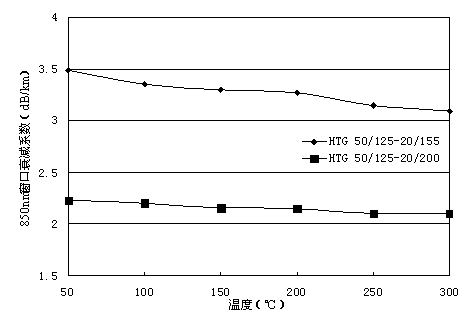

[0022] Core, cladding and coating structures such as figure 1 As shown, the multimode structure 50 / 125μm quartz optical fiber is made, and the inner and outer coatings are respectively modified silicone rubber coating layer and polyimide coating layer, wherein the modified silicone rubber coating is organic silicon Modified silicone rubber OF-180, the curing condition is 150°C heat curing for 30 minutes, the elastic modulus after curing is 1.0MPa, and the working environment temperature range is -70~300°C; the polyimide coating described is ZKPI -306I polyimide coating, the curing condition is 200 ° C for 40 minutes, the elastic modulus after curing is 3.0 GPa, the temperature resistance level of the coating is -65 ° C ~ +300 ° C, the outer diameter of the inner coating is 162 μm, The outer diameter of the coating is 202 μm. The optical fiber has an attenuation value of 2.23dB / km at 850nm, and an attenuation value of 0.42dB / km at 1300nm, and the length of the optical fiber se...

Embodiment 3

[0024] Core, cladding and coating structures such as figure 1 As shown, the multimode structure 62.5 / 125μm quartz optical fiber is made, and the inner and outer coatings are respectively modified silicone rubber coating layer and polyimide coating layer, wherein the modified silicone rubber coating is organic silicon Modified silicone rubber OF-101, the curing condition is 150 ° C for 30 minutes, the elastic modulus after curing is 1.8 MPa, and the working environment temperature range is -70 ~ 300 ° C; the polyimide coating is ZKPI -306II polyimide coating, the curing condition is 200 ° C for 35 minutes, the elastic modulus after curing is 2.8 GPa, the temperature resistance level of the coating is -65 ° C ~ +300 ° C, the outer diameter of the inner coating is 164 μ m, The outer diameter of the coating is 199 μm. The attenuation value of the optical fiber at 850nm is 2.62dB / km, the attenuation value at 1300nm is 0.51dB / km, and the length of the optical fiber section is great...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com