Rotary drum type fluid friction resistance tester

A technology of fluid friction and tester, which is applied in the direction of fluid dynamics test, machine/structural component test, instrument, etc. It can solve the problems of measurement result influence, cumbersome operation, and large space occupation, so as to achieve accurate and reliable test results and realize Stepless speed regulation, the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

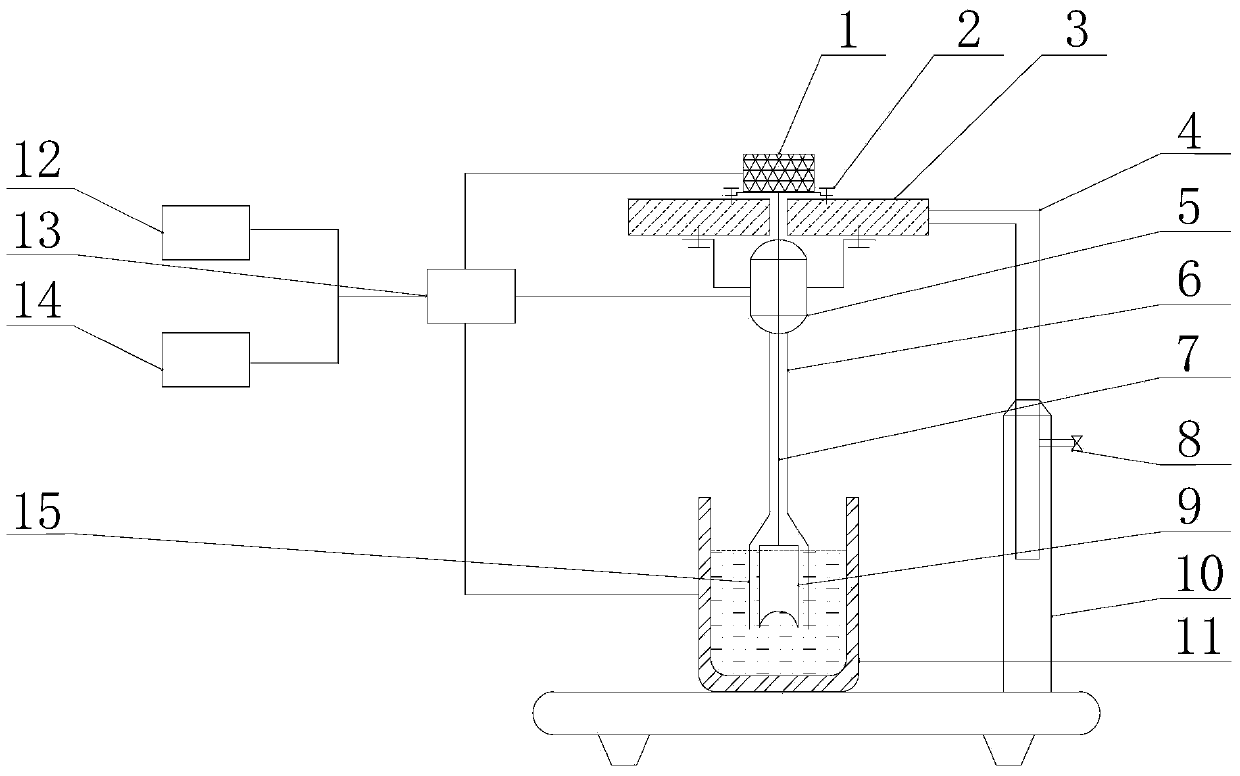

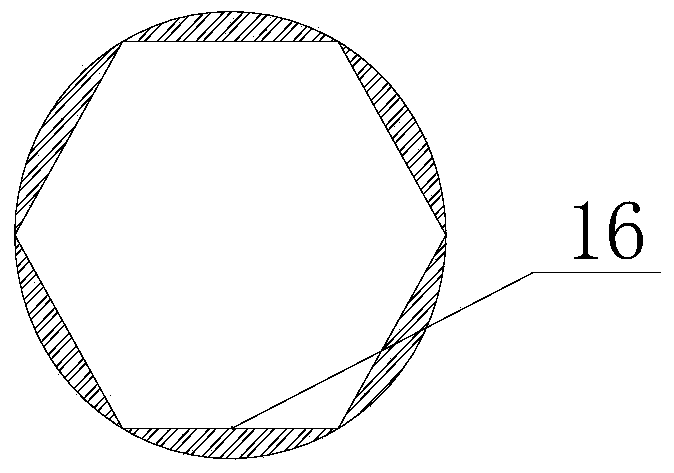

[0020] The invention is a drum-type fluid frictional resistance tester, in particular a frictional resistance device for performing resistance test analysis and evaluating fluid to different surface texture structures. The drum type fluid friction resistance tester consists of a test bench 10, a lifting rod 4, a speed regulating motor 5, an inner drum 9, an outer drum 15, a hollow rotating shaft 6, a rotating shaft 7, a torque sensor 1, and a constant temperature sample cup 11. On the vertical bar of the test bench 10, the elevating rod 4 with the horizontal cantilever is movable and fixed, and the mounting plate 3 is fixed on the horizontal cantilever of the elevating rod 4, and the torque sensor 1 and the speed regulating motor 5 are fixed on the mounting plate 3 by fastening screws 2 Above, one end of the torque sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com