Overflow cut-off valve

A cut-off valve and overflow technology, applied in safety valves, balance valves, valve devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

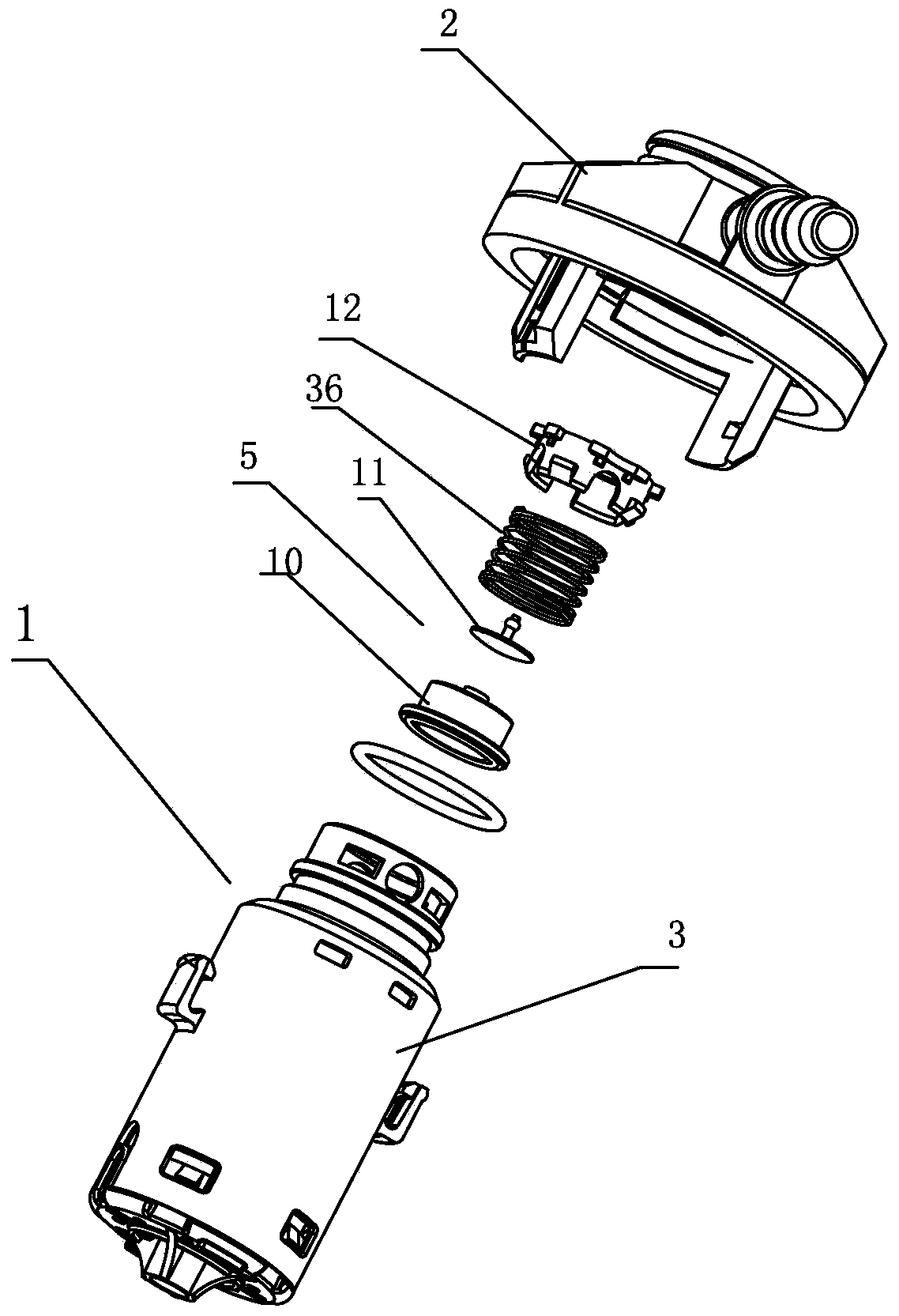

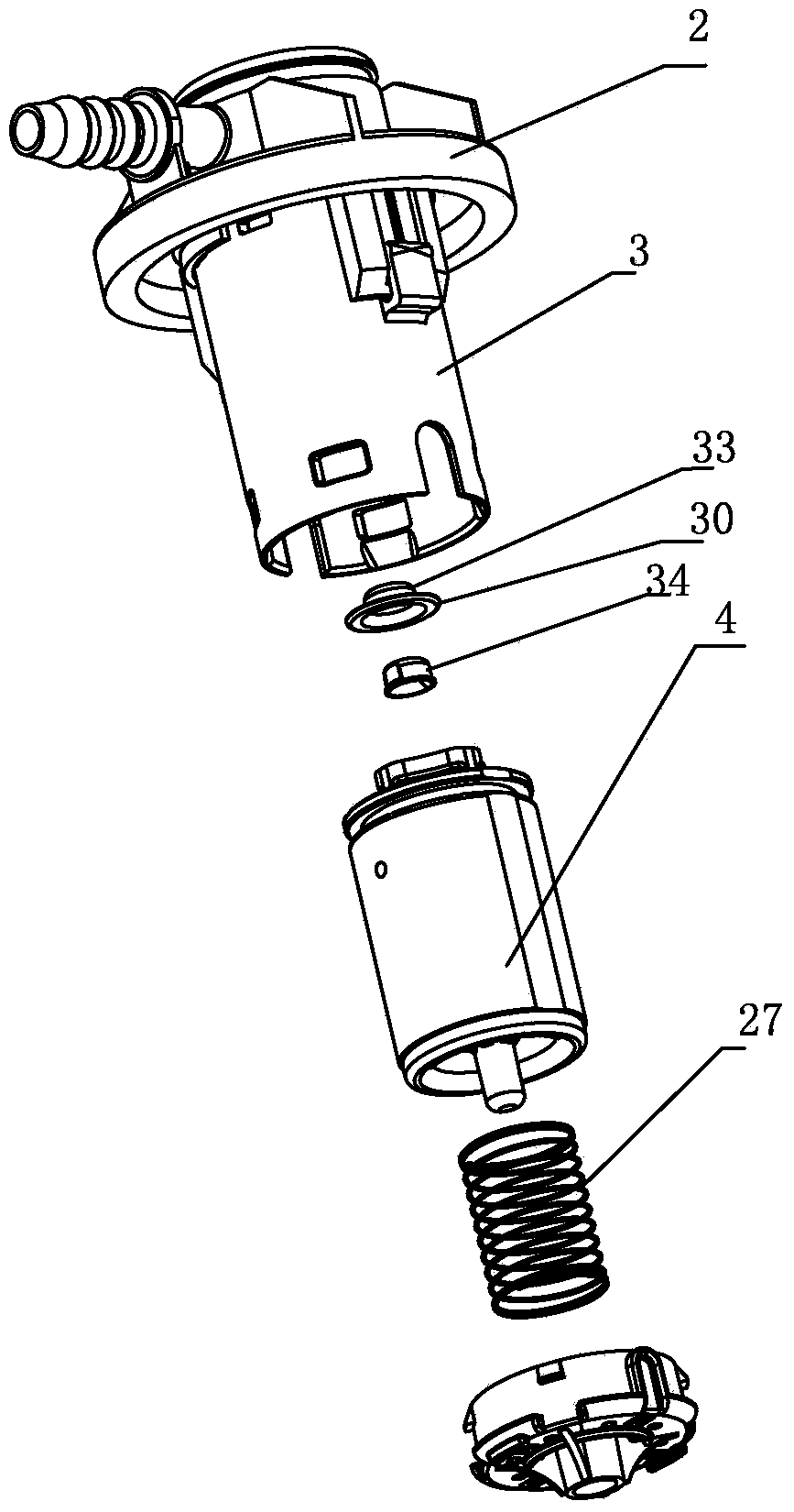

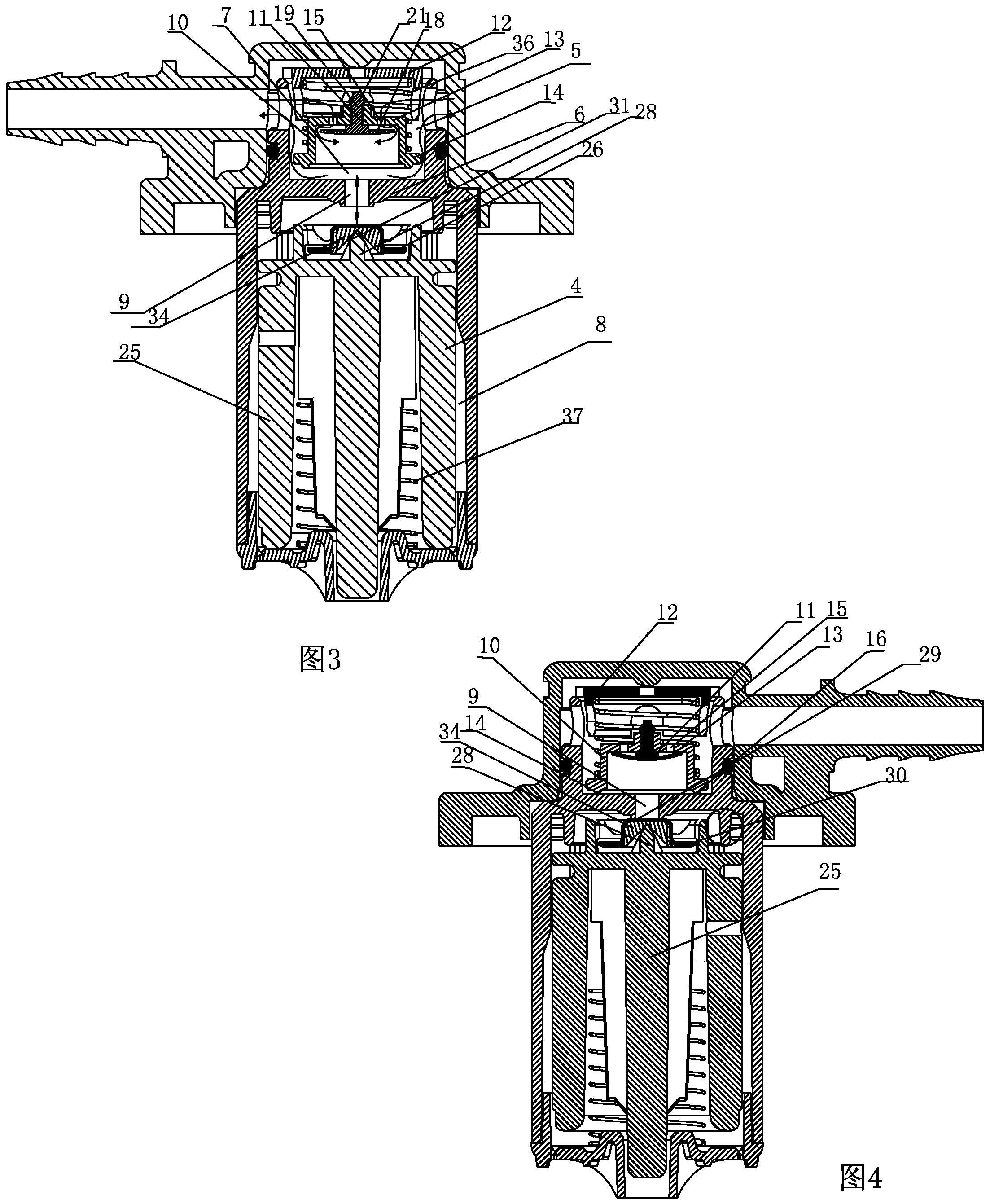

[0034] An overflow cut-off valve, including a valve body 1 and a valve cover 2, the valve cover 2 is installed on the valve body 1, the valve body 1 includes a casing 3, a valve floating core assembly 4 and a pressure maintaining assembly 5, and the casing 3 is set A partition wall 6 separates the housing 3 into an upper chamber 7 and a lower chamber 8, the partition wall 6 is provided with a vent hole 9, the valve floating core assembly 4 is arranged in the lower chamber 8, and the pressure maintaining assembly 5 is arranged in the upper chamber 8, The pressure holding assembly 5 includes a cylindrical pressure holding plastic part 10, a rubber assembly 11, a cover 12 and a first return spring 36, the cover 12 is fixed on the housing 3,

[0035] The lower end of the pressure-holding plastic part 10 is open, and the vent hole 9 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com