Counterweight-discrete flywheel

A discrete, flywheel technology, applied in the field of flywheels, can solve the problems of variable inertia demand of flywheels, inability to meet equipment requirements, etc., and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

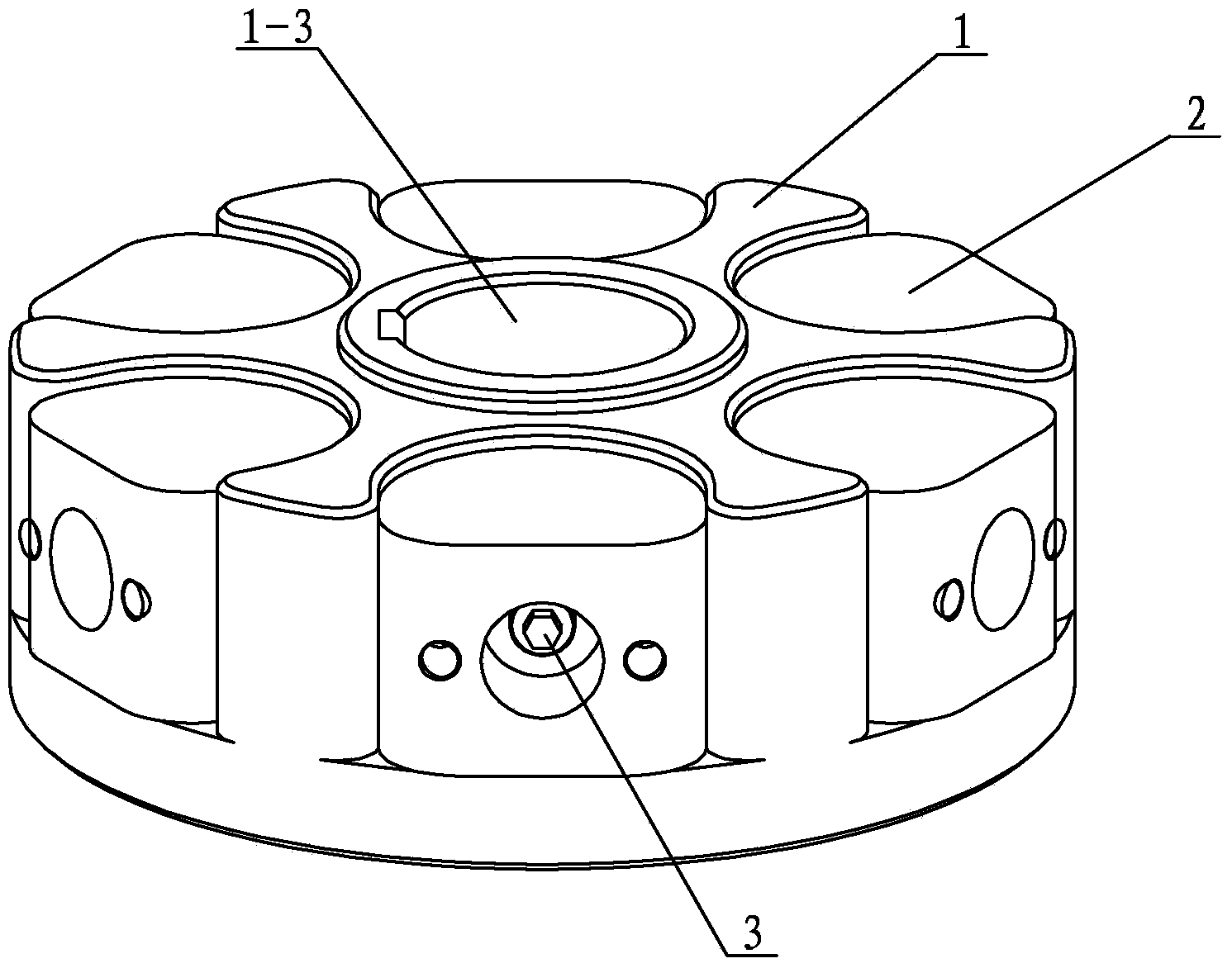

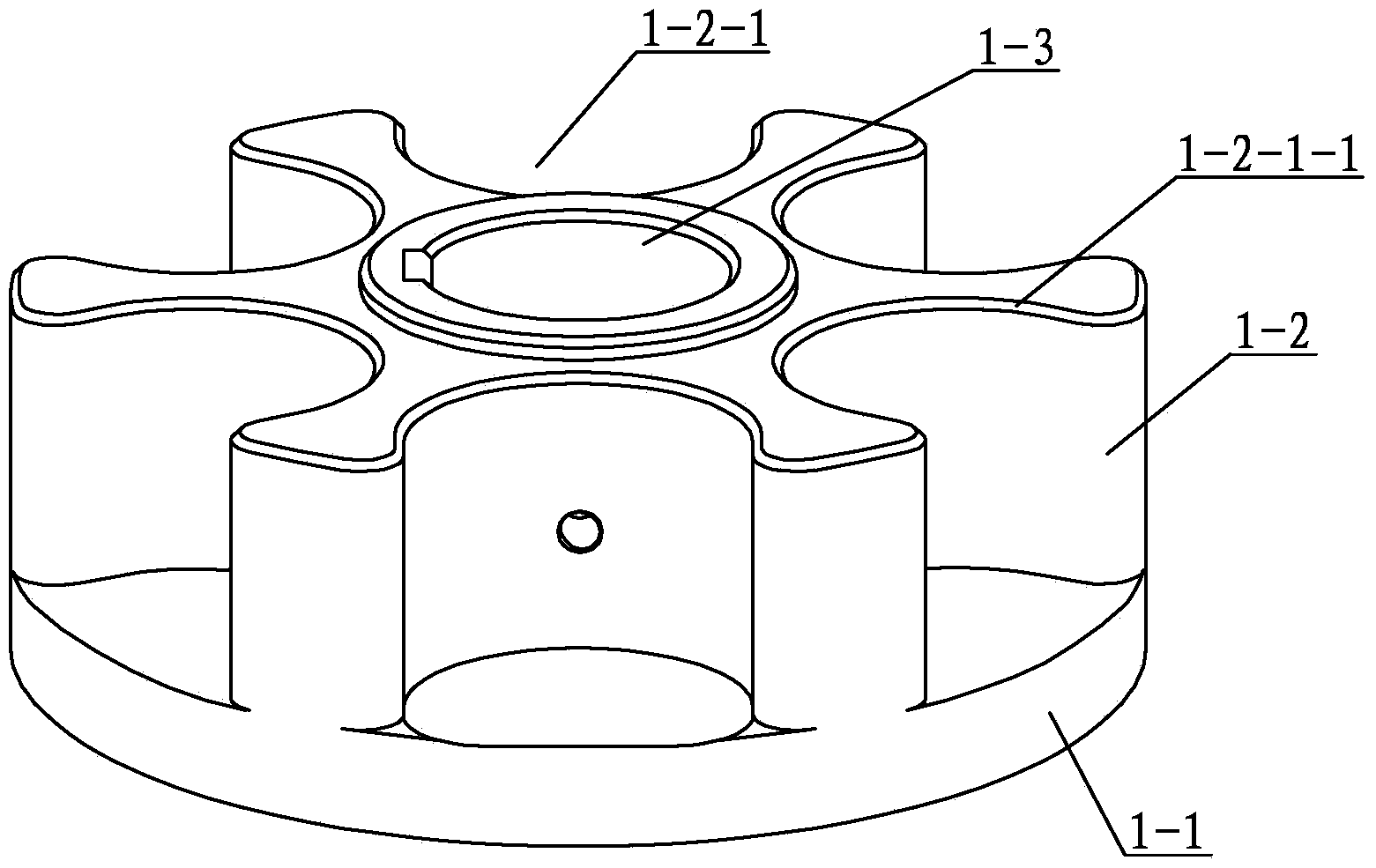

[0009] Specific implementation mode one: combine figure 1 and Fig. 3 illustrate this embodiment, the counterweight weight discrete flywheel of this embodiment includes a flywheel base 1 and several flywheel weights 2, and the flywheel base 1 is composed of a base 1-1 and a flywheel weight seat 1- 2, the base 1-1 is in the shape of a disk, the flywheel weight seat 1-2 is coaxially arranged up and down with the base 1-1, and the flywheel base 1 is provided with a central axis hole along the axis 1-3, the flywheel weight seat 1-2 is uniformly processed with four to eight semicircular grooves 1-2-1 along the periphery, and a flywheel weight is installed in each semicircular groove 1-2-1 Code 2, the flywheel weight 2 is connected with the flywheel base 1 through screws 3. When in use, pass one end of the engineering shaft through the center shaft hole 1-3 and fix it through the keyway.

specific Embodiment approach 2

[0010] Specific Embodiment 2: This embodiment is described with reference to FIG. 2 . The flywheel weight base 1-2 of this embodiment is integrated with the base 1-1. This design increases the stability of the flywheel base 1 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific Embodiment 3: This embodiment is described with reference to FIG. 2 . The number of semicircular grooves 1-2-1 in this embodiment is six. Design like this in order to ensure that the number of flywheel weights 2 is six. This number of flywheel weights 2 is the optimum value to meet the equipment requirements. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com