Double-circle steel wire rope shock absorber

A technology of steel wire rope and shock absorber, which is applied in the field of double-loop steel wire rope shock absorber, which can solve the problems that it is difficult to maintain a relatively stable state, large damping and stiffness of the shock absorber, etc., so as to improve the ability to deal with accidents and increase the stiffness Stability and the effect of overcoming poor resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will be specifically described in conjunction with the accompanying drawings of the embodiments.

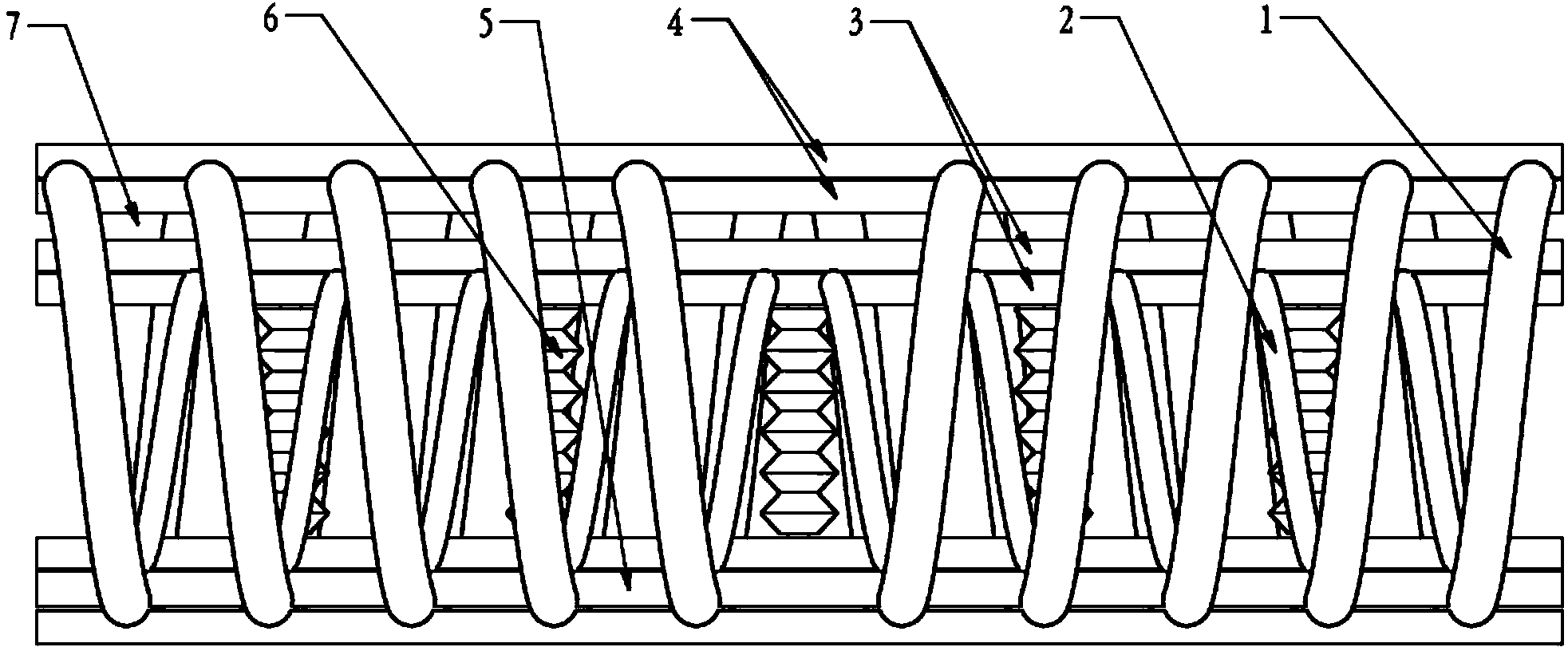

[0022] Such as figure 1 with figure 2 :

[0023] In the figure: 1-steel wire rope of the outer ring, 2-steel wire rope of the inner ring, 3-upper splint of the inner ring, 4-upper splint of the outer ring, 5-lower splint, 6-Butterfly spring group, 7-pre-top clearance.

[0024] The inner ring wire rope 1 and the outer ring wire rope 2 are composed of two parts, the left side and the right side. The inner ring wire rope 1 and the outer ring wire rope 2 rotate in opposite directions, and each forms a left-right symmetrical structure; the inner ring wire rope 1 on the left or right side The winding direction of the wire rope located at the same position as the outer ring wire rope 2 is opposite. In the unloaded free state of the shock absorber, there is a pre-top gap 7 between the upper clamping plate 3 of the inner ring and the upper clamping plate 4 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com