Extrusion equipment for egg tart skin forming

A technology of extrusion equipment and egg tart skin, which is applied in the direction of dough extruder, etc., can solve the problems of low safety and compression, and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

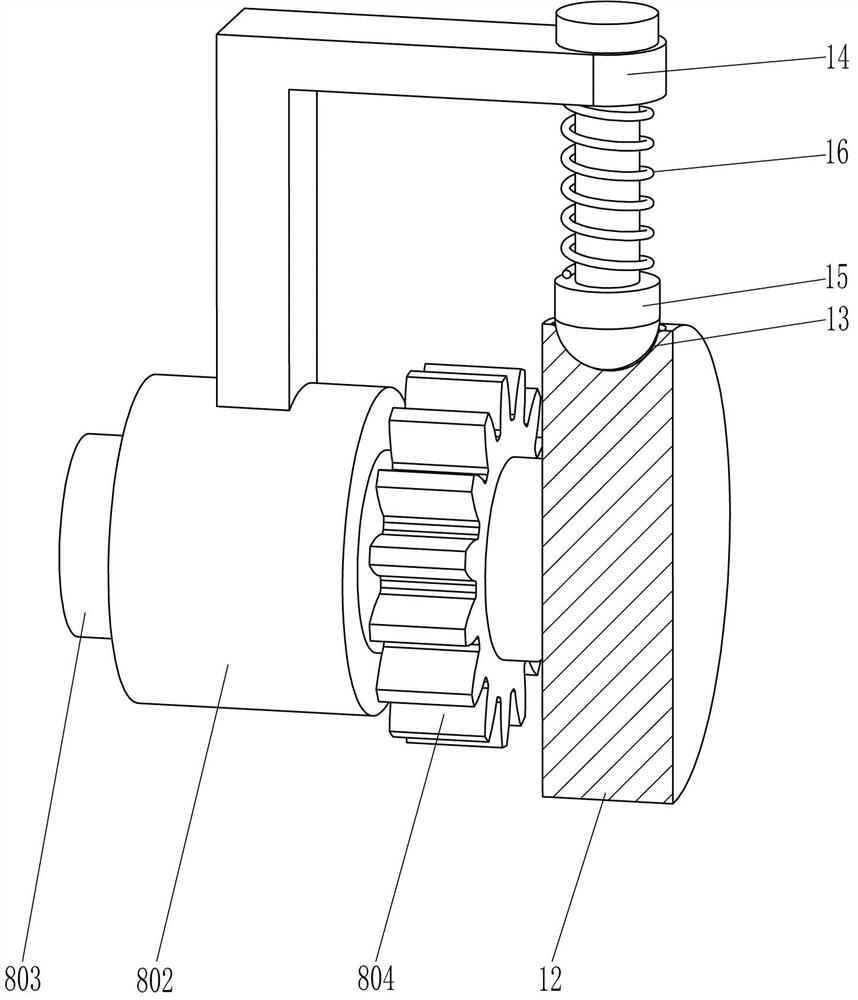

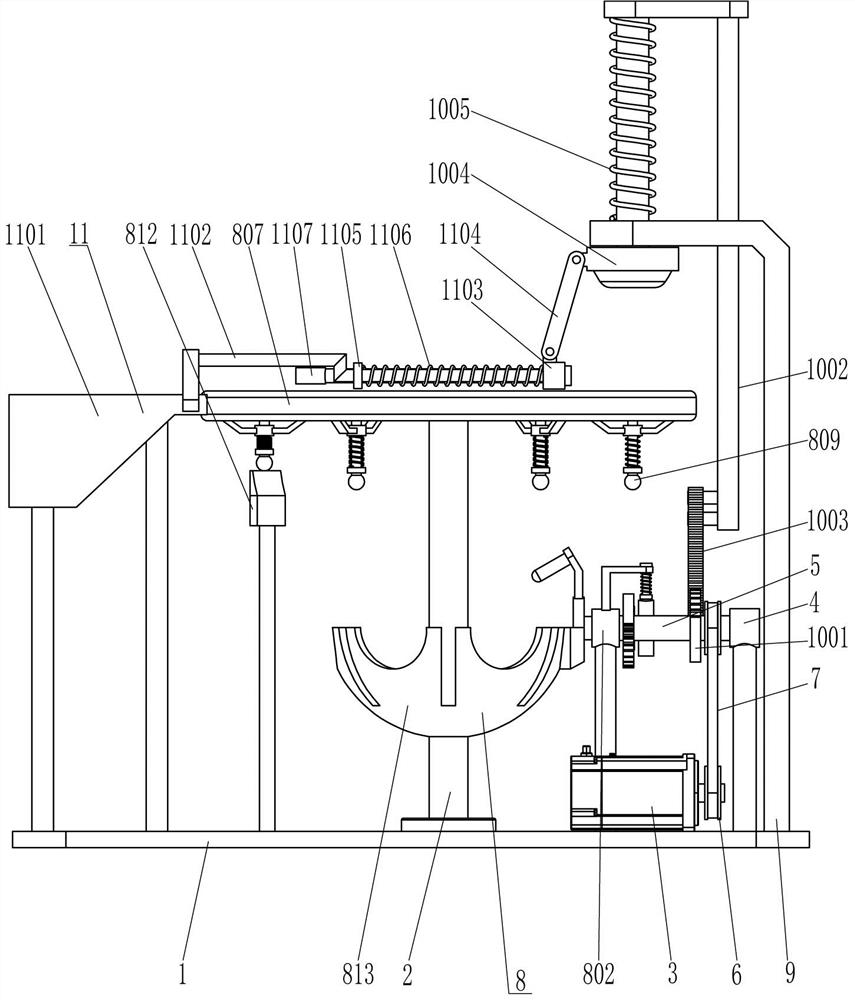

[0023] A kind of extruding equipment for egg tart shell forming, such as Figure 1-5 As shown, it includes a base plate 1, a first rotating shaft 2, a servo motor 3, a pole 4, a second rotating shaft 5, a transmission wheel 6, a belt 7, a rotating assembly 8, a support frame 9 and an extruding assembly 10, and the middle of the top of the base plate 1 The first rotating shaft 2 is installed in rotation through the bearing seat, and the servo motor 3, the support rod 4 and the support frame 9 are installed on the right side of the top of the bottom plate 1 through bolts, the support rod 4 is located between the servo motor 3 and the support frame 9, and the support rod 4 The upper part is rotatably equipped with a second rotating shaft 5, a transmission wheel 6 is installed on the second rotating shaft 5, and a transmission wheel 6 is also installed on the output shaft of the servo motor 3, and a belt 7 is wound between the two transmission wheels 6, and the first rotating shaft...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , figure 2 and Figure 4 As shown, it also includes a discharge assembly 11. The discharge assembly 11 includes a collection bucket 1101, a support rod 1102, a slide block 1103, a connecting rod 1104, a fixed ring 1105, a third spring 1106 and a push plate 1107, and the top left of the base plate 1 The side is equipped with a collection bucket 1101 through three installation rods, the collection bucket 1101 is located on the left side of the arc wedge block 812, the collection bucket 1101 is in contact with the placement plate 807, the front and rear sides of the collection bucket 1101 are connected with support rods 1102, two support rods 1102 The upper sliding type is provided with a slider 1103, the top of the slider 1103 is rotatably connected to a connecting rod 1104, the top of the connecting rod 1104 is rotatably connected to the extruding block 1004, and the two support rods 1102 are connected with a fixed ring 1105,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com