Preparation method of hydroxyapatite microspheres

A technology of hydroxyapatite and microspheres, which is applied in the field of preparation of hydroxyapatite microspheres, can solve the problems of slow reaction process and unfavorable rapid production, and achieve the effects of rapid reaction, pollution avoidance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

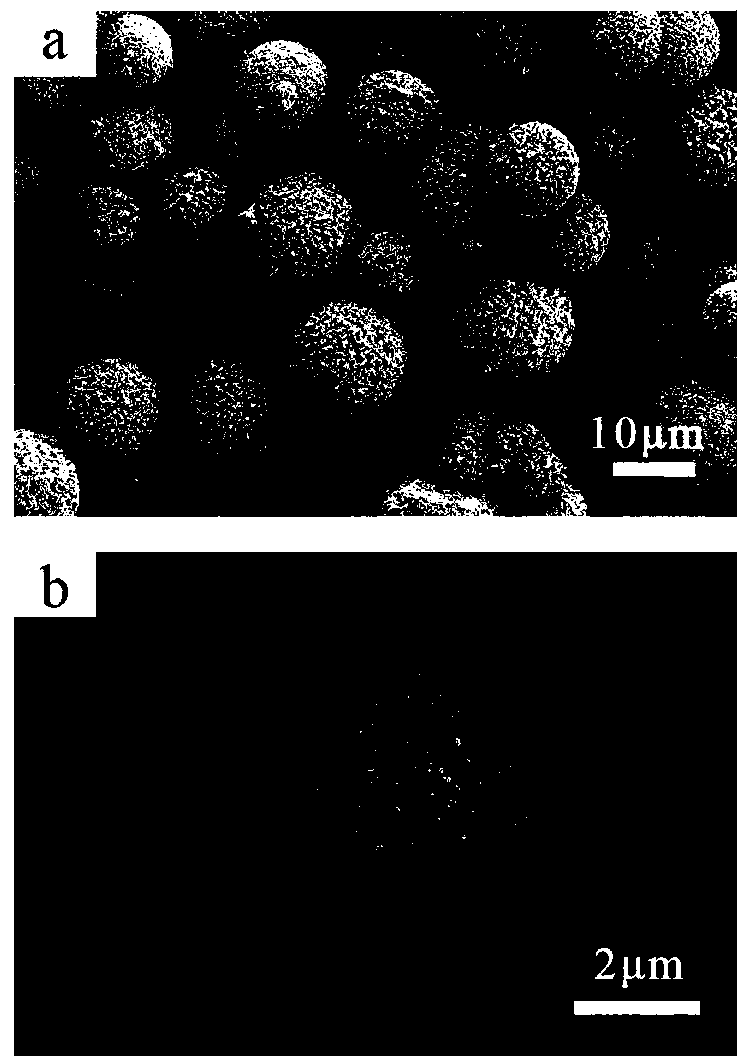

Embodiment 1

[0028] (1) 0.434g disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) Dissolve in 200ml deionized water to make a phosphate solution.

[0029] (2) Slowly add sodium hydroxide with a concentration of 1 mol / L dropwise to the above solution while stirring until the pH value reaches 10.

[0030] (3) Add 0.2g of calcium carbonate particles to the phosphate solution in step (2), and keep stirring to form a suspension.

[0031] (4) Put the obtained suspension into a microwave oven, adjust the microwave power to 80W, and the reaction time to 15min, and carry out microwave heating reaction.

[0032] (5) Suction filter the reacted solution with a microporous filter membrane with a pore size of 0.1 μm, wash the obtained filter cake with deionized water and absolute ethanol alternately for 3 times each, and then put it into 40 o The hydroxyapatite microspheres were obtained after drying in a constant temperature drying oven in C for 24 hours.

[0033] After testing: the main phase of t...

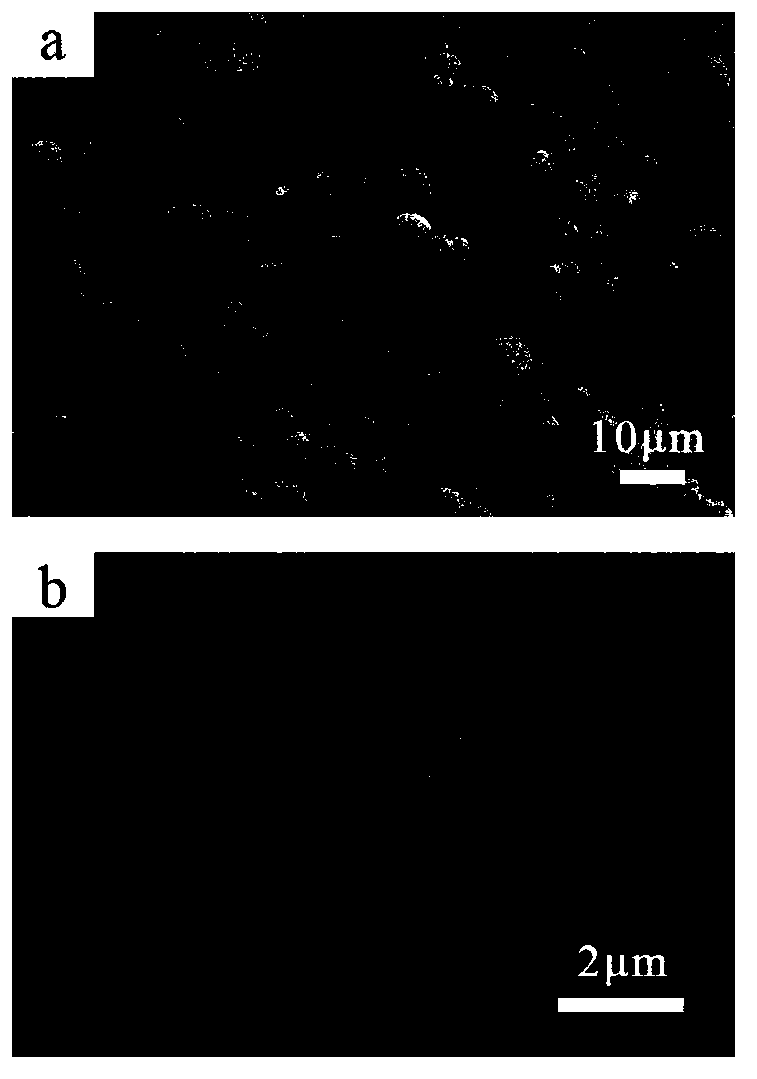

Embodiment 2

[0035] (1) 1.808g disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) Dissolve in 200ml deionized water to make a phosphate solution.

[0036] (2) Slowly add 1mol / L sodium hydroxide dropwise to the above solution while stirring until the pH value reaches 10.

[0037] (3) Add 0.2g of calcium carbonate particles to the phosphate solution in step (2), and keep stirring to form a suspension.

[0038] (4) Put the obtained suspension into a microwave oven, adjust the microwave power to 100W, and the reaction time to 5min, and carry out microwave heating reaction.

[0039] (5) Suction filter the heated solution with a microporous filter membrane with a pore size of 0.1 μm, wash the obtained filter cake with deionized water and absolute ethanol alternately for 4 times each, and then put it in a constant temperature drying oven at 40°C After drying for 48 hours, hydroxyapatite microspheres were obtained.

[0040] After testing: the main phase of the microspheres prepared in Example 2...

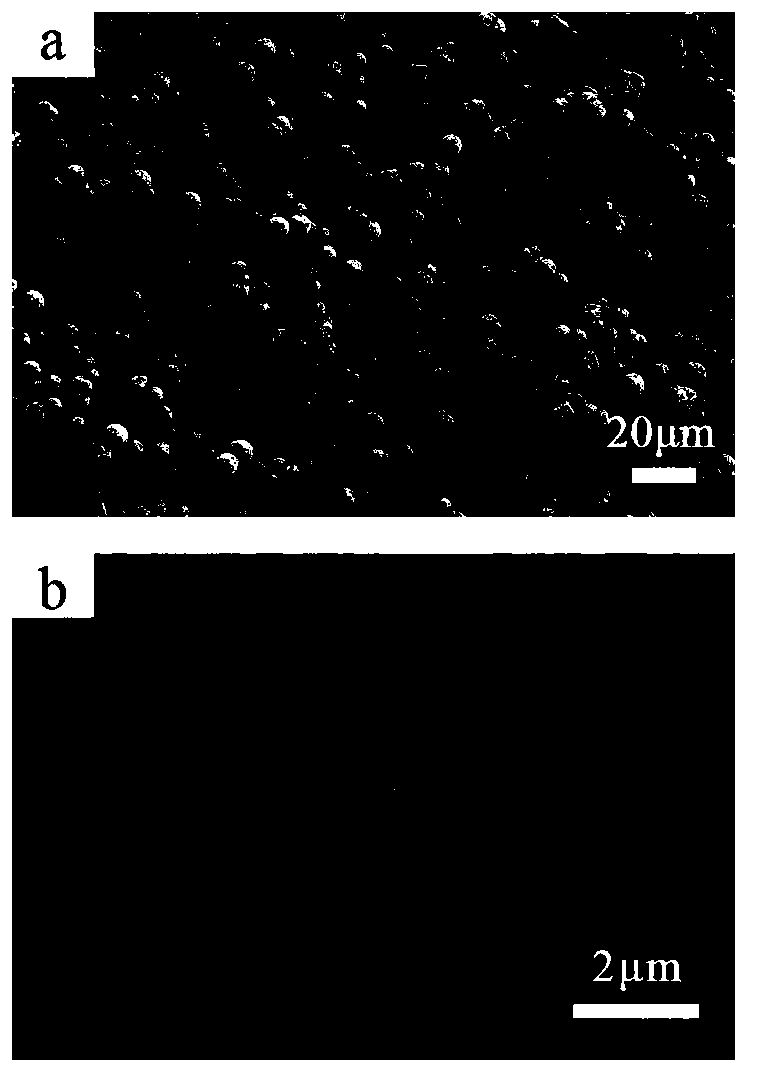

Embodiment 3

[0042] (1) 3.616g disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) Dissolve in 200ml deionized water to make a phosphate solution.

[0043] (2) Slowly add 0.1mol / L sodium hydroxide dropwise to the above solution while stirring until the pH value reaches 10.

[0044] (3) Add 0.2g of calcium carbonate particles to the phosphate solution in step (2), and keep stirring to form a suspension.

[0045] (4) Put the obtained suspension into a microwave oven, adjust the microwave power to 60W, and the reaction time to 15min, and carry out microwave heating reaction.

[0046] (5) Suction filter the reacted solution with a microporous filter membrane with a pore size of 0.15 μm, wash the obtained filter cake with deionized water and absolute ethanol alternately for 3 times, and then put it into 60 o The hydroxyapatite microspheres were obtained after drying in a constant temperature drying oven in C for 24 hours.

[0047] After testing: the main phase of the microspheres prepared in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com