Portable pressure swing adsorption oxygen generation device

A pressure swing adsorption oxygen production, portable technology, applied in the direction of oxygen preparation, can solve the problems of high processing cost, difficult processing, damage to the molecular base structure, etc., to achieve convenient carrying and handling, reduce assembly difficulty, and compact assembly space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

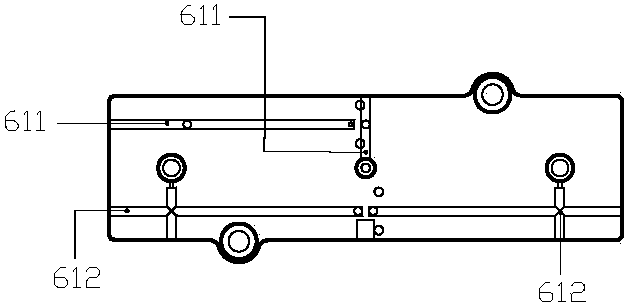

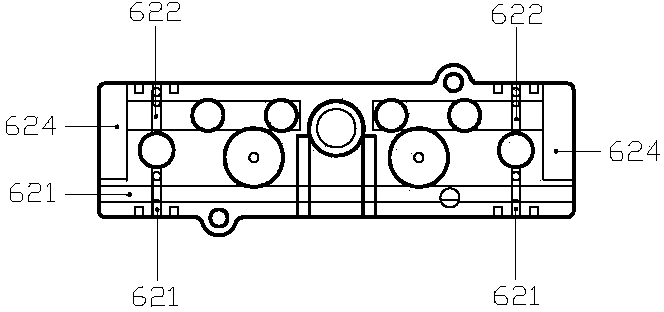

[0057] Such as Figure 1-Figure 8 As shown, a portable pressure swing adsorption oxygen generator of this embodiment includes a body fixing frame 1, and the body fixing frame 1 is provided with a power supply 2 and a PCB board 3, and the PCB board 3 and the power supply 2 are electrically connected, and the body The fixed frame 1 is equipped with a molecular tube cover manifold, and the molecular tube cover manifold is equipped with an air pump 4, a molecular sieve tube group and an air storage tank 7, and the molecular sieve tube group includes two molecular sieve tubes 5, and the molecular tube cover manifold includes Molecular tube upper cover manifold 61 and molecular tube lower cover manifold 62, two molecular sieve tubes 5 are sandwiched between the molecular tube upper cover manifold 61 and the molecular tube lower cover manifold 62 respectively, the molecular tube upper cover converges The plate 61 is provided with an oxygen channel 611 and an oxygen complementary chan...

Embodiment 2

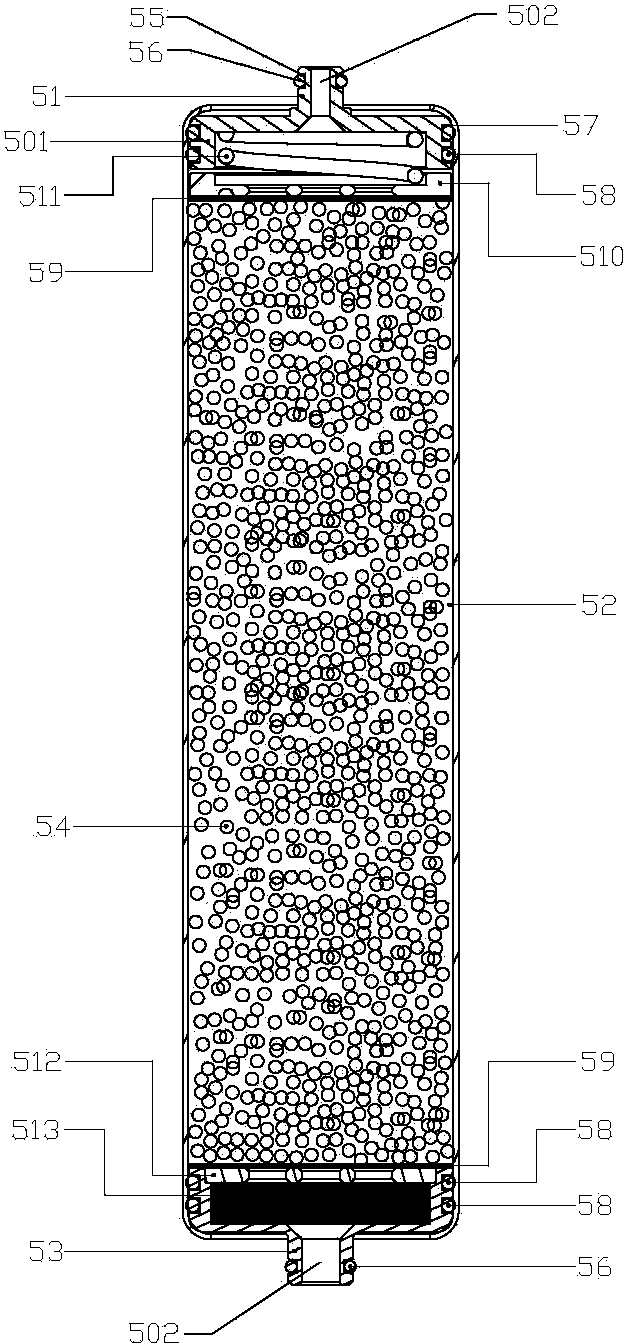

[0068] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, the molecular sieve tube 5 of this embodiment includes a molecular tube upper cover 51, a molecular tube body 52 and a molecular tube lower cover 53 installed sequentially from top to bottom, the molecular tube body 52 is filled with an adsorbent 54, and the molecular tube body 52 is filled with an adsorbent 54. Between the molecular tube upper cover 51 and the molecular tube body 52 , between the molecular tube lower cover 53 and the molecular tube body 52 are integrally die-casted by a die-casting jig.

[0069] Specifically, the molecular tube upper cover 51, the molecular tube body 52, and the molecular tube lower cover 53 are all made of aluminum, and the wall thicknesses of the molecular tube upper cover 51, the molecular tube body 52, and the molecular tube lower cover 53 are all 1-5 mm. Left and right, under the action of the die-casting fixture, the pressure value is 0.3-0.8T ...

Embodiment 3

[0080] The difference between this embodiment and embodiment 1 is that, as Figure 5 As shown, the air intake end of the air pump 4 of the present embodiment is connected with an air intake filter device 9, the intake filter device is installed on the manifold of the lower cover of the molecular tube, and the air intake port of the air channel is provided with an air intake joint. The air outlet end of the air pump 4 communicates with the air inlet joint 623 through an air guide tube. The air intake filter device 9 is used for air intake filtration to prevent impurities such as moisture and dust in the air from entering the molecular sieve tube 5, which is conducive to improving the oxygen production effect and prolonging the service life of the molecular sieve tube 5.

[0081] Such as Figure 8 As shown, specifically, the air pump 4 and the air intake filter device 9 are respectively arranged on the manifold 62 of the lower cover of the molecular tube, and the air inlet joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com