Method for changing connecting tubes in FPSO (floating production storage and offloading) single-point buoys

A replacement method and technology for connecting pipes, which is applied in ship construction, ships, ship parts, etc., can solve the problems of dismantling many things, heavy workload, and narrow time window for single-point connecting pipes, so as to reduce risks and save construction costs , the effect of widening the time window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

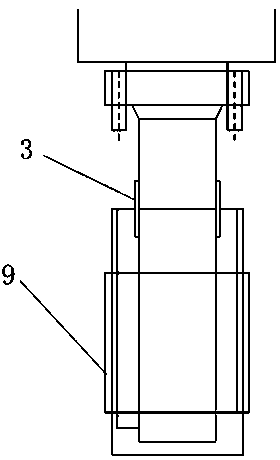

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

[0038] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the connecting pipe replacement method in the FPSO single-point buoy of the present invention comprises the following steps:

[0039] S1. Preparations before replacement:

[0040] S11. The test of the single-point turret ensures the normal operation of the single-point turret, the installation and positioning of the auxiliary winch 1, the placement of the pulley blind plate 2, the disassembly of the sealing capsule, and the tightening of the temporary fixing block screws after loosening;

[0041] S12. The anti-collision pad is installed on the construction ship site, the reverse mooring cable is in place, and the towed ship has been towed to lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com