Assembly equipment for tumbler lock springs and closures

A technology for assembling equipment and marbles, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve problems such as prone to mechanical failures, very high accuracy requirements, and affecting product processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

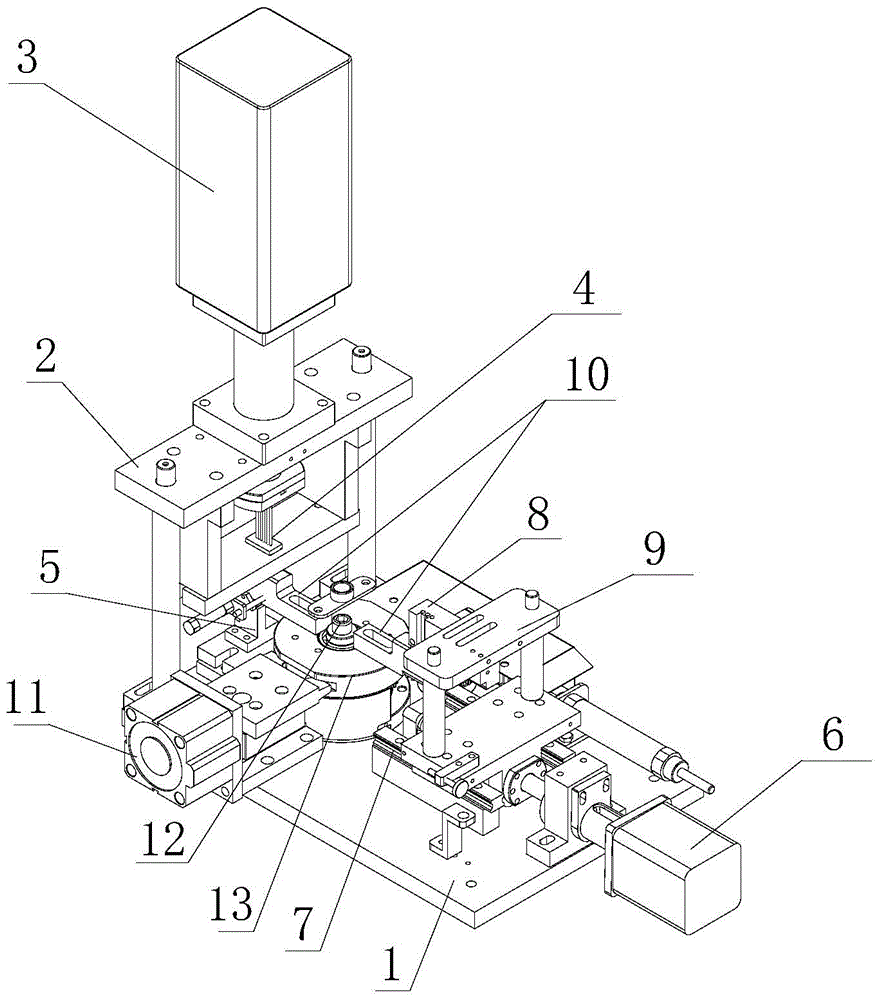

[0009] Attached below figure 1 The present invention is further described.

[0010] like figure 1 The assembly equipment for pin lock springs and shell closures of the present invention comprises a base 1 and a stamping device and a feeding device installed thereon.

[0011] The punching device includes a punching frame 2, a punching cylinder 3, a punching needle handle 4 and a lock fixture 5, the punching frame 2 is fixed on the base 1, the punching cylinder 3 is installed on the punching frame 2, and the punching die handle 4 is installed on the punching cylinder On the output end of 3, the stamping cylinder 3 drives the punching needle handle 4 to move vertically up and down in the stamping frame 2, and the lock fixture 5 is directly below the punching needle handle 4.

[0012] The feeding device comprises a stepping motor 6, a linear guide rail 7, a spring sealing ejector 8, a mounting frame 9, a feeding cylinder, a rotary mechanism and two rotary stockers 10 with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com