Fermentation drying device used for treating kitchen wastes

A kitchen waste, fermentation and drying technology, applied in the field of fermentation and drying equipment for kitchen waste treatment, can solve the problems of cumbersome production, unreasonable structure, slow processing speed, etc., achieve faster steam flow rate, faster drying speed, and prevent The effect of repeated condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

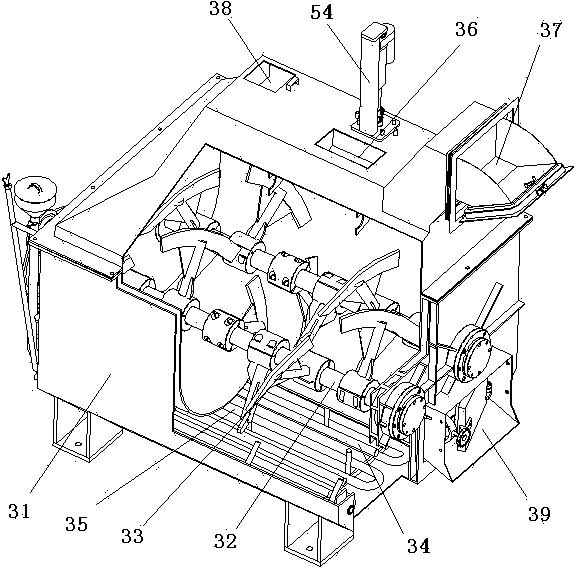

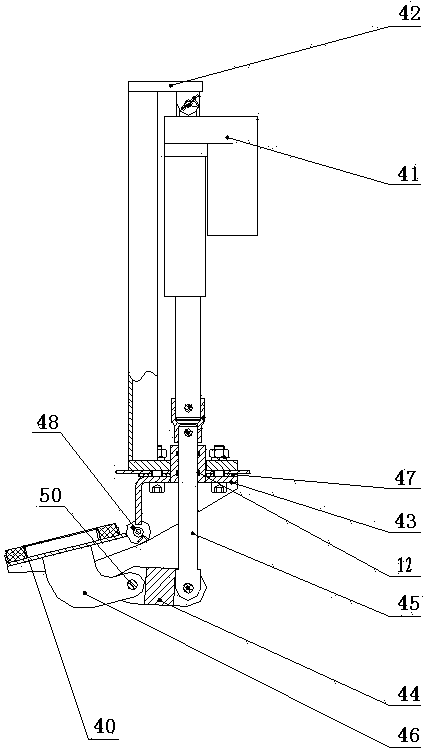

[0029] Embodiment 1: as attached figure 1 As shown, a fermentation and drying device for treating kitchen waste is characterized in that it includes a fermentation tank 31, a stirring shaft 32, a temperature sensor, a heating element, and an automatic door closing device. The fermentation tank 31 is provided with a stirring shaft 32. The top surface of the tank 31 is provided with a feeding port 36 and a bacterium injection port 37, a heating element is provided at the bottom, an exhaust port 38 and a temperature sensor are provided on the side wall, so that the temperature sensor controls the heating temperature, and a discharge port is provided on the lower side 39. The feed port 36 corresponds to the kitchen waste outlet at the lower end of the sorting device. The bacteria feeding port 37 is provided with a sealed door, the discharge port 39 is provided with a discharge door, and the feed port 36 is provided with an automatic door closing device. , the stirring shaft 32 is...

Embodiment 2

[0030] as attached figure 1As shown, embodiment 2: a fermentation and drying device for the treatment of kitchen waste, which is characterized in that it includes a fermentation tank 31, a stirring shaft 32, a temperature sensor, a heating element and an automatic door closing device, and the fermentation tank 31 is equipped with a stirring Shaft 32, fermenter 31 top surface is provided with feed inlet 36 and bacterium injection port 37, and bottom is provided with heating element, and one side wall is provided with exhaust port 38 and temperature sensor, so that temperature sensor controls heating temperature, and bottom side is provided with There is a discharge port 39, and the feed port 36 is corresponding to the kitchen waste outlet at the lower end of the sorting device. The bacteria injection port 37 is provided with a sealing door, the discharge port 39 is provided with a discharge door, and the feed port 36 is provided with a There is an automatic door closing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com