Drying oven tuyere of lithium cell pole piece coating machine

A lithium battery and pole piece technology, applied in the field of new energy equipment, can solve the problems affecting the uniformity of drying air volume and heat, affecting the strength and uniformity of the pole piece, and affecting the uniformity and consistency of the pole piece, and achieves a simple structure. Clever, performance-enhancing, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

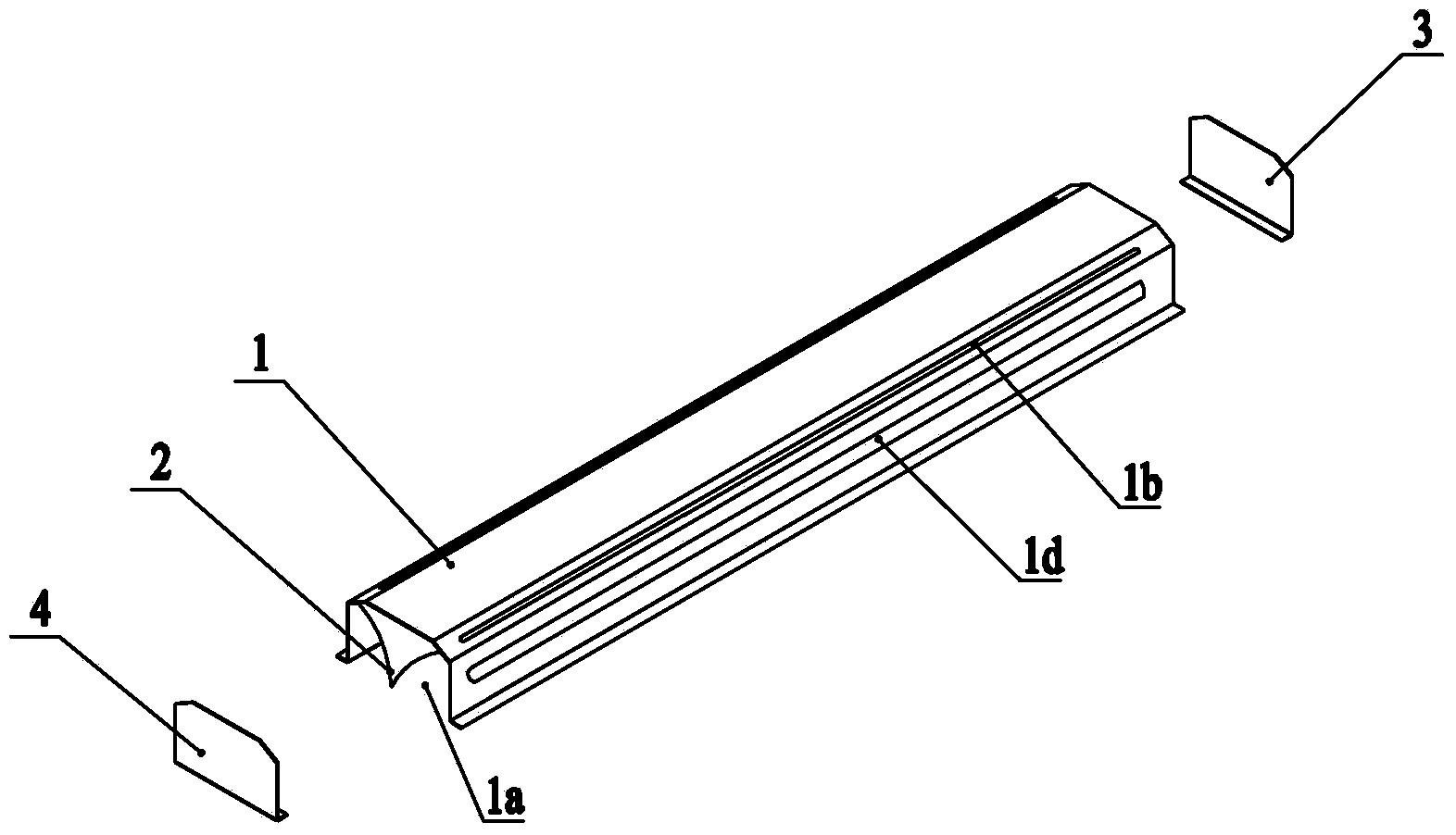

[0017] As shown in the figure: the oven nozzle of the lithium battery pole piece coating machine in the embodiment is mainly composed of a main casing 1, an air deflector 2, a left side plate 3 and a right side plate 4.

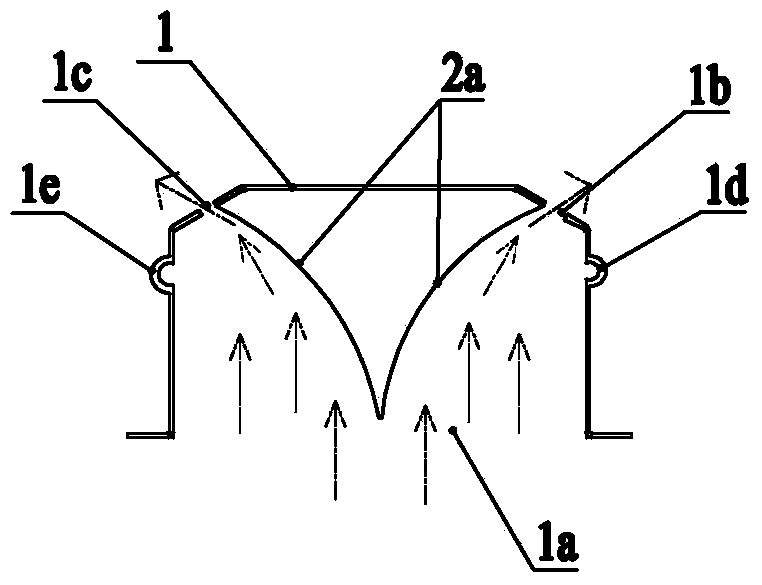

[0018] Such as figure 1 , figure 2 As shown, the lower part of the main housing 1 is open as the air inlet 1a, and the front and rear air outlets 1b and 1c arranged along the length direction of the main housing 1 are arranged on the inclined surfaces of the front and rear sides of the top panel of the main housing 1. The left and right ends of the housing 1 are respectively connected to the left side plate 3 and the right side plate 4, and the main housing 1 is provided with a wind deflector 2 inside, and the wind deflector 2 is in the shape of a bird’s wing in cross section. Wind deflector 2, the tops of the two wing plates 2a of the bir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com