Coal tar filtering device and method

A filtering device and technology for coal tar, applied in the field of coal chemical industry, can solve the problems of easy blocking of filter elements, high frequency of backflushing, low filtering efficiency, etc., and achieve the effects of reducing the amount of dirty oil, stable operation of equipment and simple filtering method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The coal tar filtering device of this embodiment is composed of 10 canister filters connected in parallel, and one canister filter communicates with an adjacent canister filter through a pipeline.

[0034] The construction of each canister filter see figure 1 , consisting of a tank body 1 and a filtered residual oil collection chamber, a filtrate collection chamber and a filter chamber distributed in the inner cavity of the tank body 1 from top to bottom. The top of the tank body 1 in this embodiment is processed with a residual oil outlet and a safety valve interface, and the bottom is funnel-shaped. A safety valve 3 is installed on the safety valve interface. A sewage outlet is processed at the bottom of the tank body 1, and a sewage discharge valve is installed on the sewage outlet. 12. Control the discharge of residue through the blowdown valve 12 switch.

[0035] The residual oil collection chamber after filtration in this embodiment is in the upper section of the...

Embodiment 2

[0048] In this embodiment, the coal tar filtering device is composed of 8 canister filters connected in parallel, and one canister filter communicates with an adjacent canister filter through a pipeline.

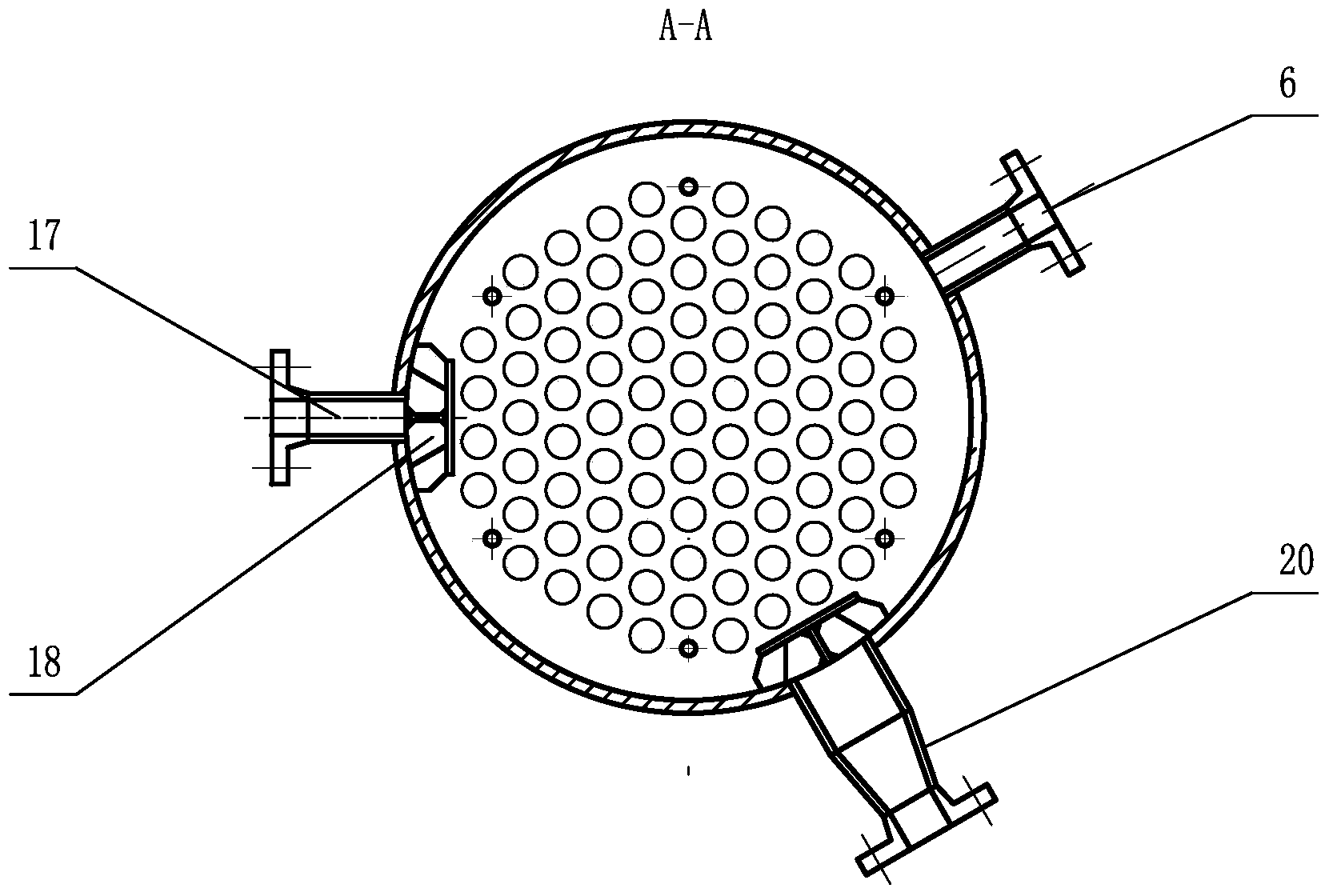

[0049] In the tank filter of this embodiment, 60 filter elements 10 are installed between the filter element upper fixing plate 16 and the filter element lower fixing plate 11, and the upper and lower ends of the filter element 10 are respectively fixed in the upper filter element fixing hole and the filter element lower fixing hole by nuts , the filter element 10 of the present embodiment adopts a Johnson filter element, and its filtration accuracy reaches 15 μm, and is distributed in an equilateral triangle in the filter chamber, and the distance between one filter element 10 and an adjacent filter element 10 is 90 mm.

[0050] Other components and their connections are the same as those in Embodiment 1.

[0051] The method that coal tar is filtered with above-mentioned fi...

Embodiment 3

[0053] In this embodiment, the coal tar filtering device is composed of 16 canister filters connected in parallel, and one canister filter communicates with an adjacent canister filter through a pipeline.

[0054] In the tank filter of this embodiment, 90 filter elements 10 are installed between the filter element upper fixing plate 16 and the filter element lower fixing plate 11, and the upper and lower ends of the filter element 10 are respectively screwed into the upper filter element fixing hole and the filter element lower fixing hole. , the filter element 10 of the present embodiment adopts a Johnson filter element, and its filtration accuracy reaches 1 μm, and is distributed in an equilateral triangle in the filter chamber, and the distance between one filter element 10 and an adjacent filter element 10 is 60 mm.

[0055] Other components and their connections are the same as those in Embodiment 1.

[0056] The method that coal tar is filtered with above-mentioned filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com