Titanium slab for hot rolling and process for producing same

A manufacturing method and slab technology, applied in the field of hot-rolled titanium slab and its manufacturing, can solve the problems of rising production costs, equipment constraints, long time, etc., and achieve the effect of improving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

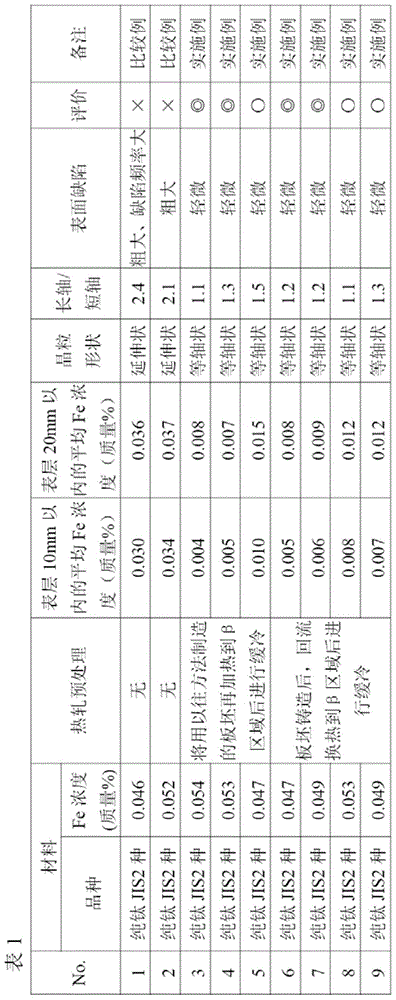

[0054] Hereinafter, the present invention will be described in detail through examples.

[0055] Examples and comparative examples shown in Table 1 use an electron beam smelting furnace to manufacture titanium slabs according to JIS 2 types of industrial pure titanium (for the raw materials used this time, the average Fe concentration at 3 points of the slab is 0.04 to 0.06 mass %) from the slab. The titanium slab is subjected to surface cutting processing after casting, and is hot-rolled by hot-rolling equipment for iron and steel materials to form a strip-shaped coil. In addition, the evaluation of the surface defect of the surface layer of the board|plate after pickling was carried out visually.

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com