A kind of positive electrode material of lithium-sulfur battery and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems of limited ability to adsorb active substance sulfur, poor conductivity, etc., to achieve inhibition of dissolution, high Utilization rate, greatly improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

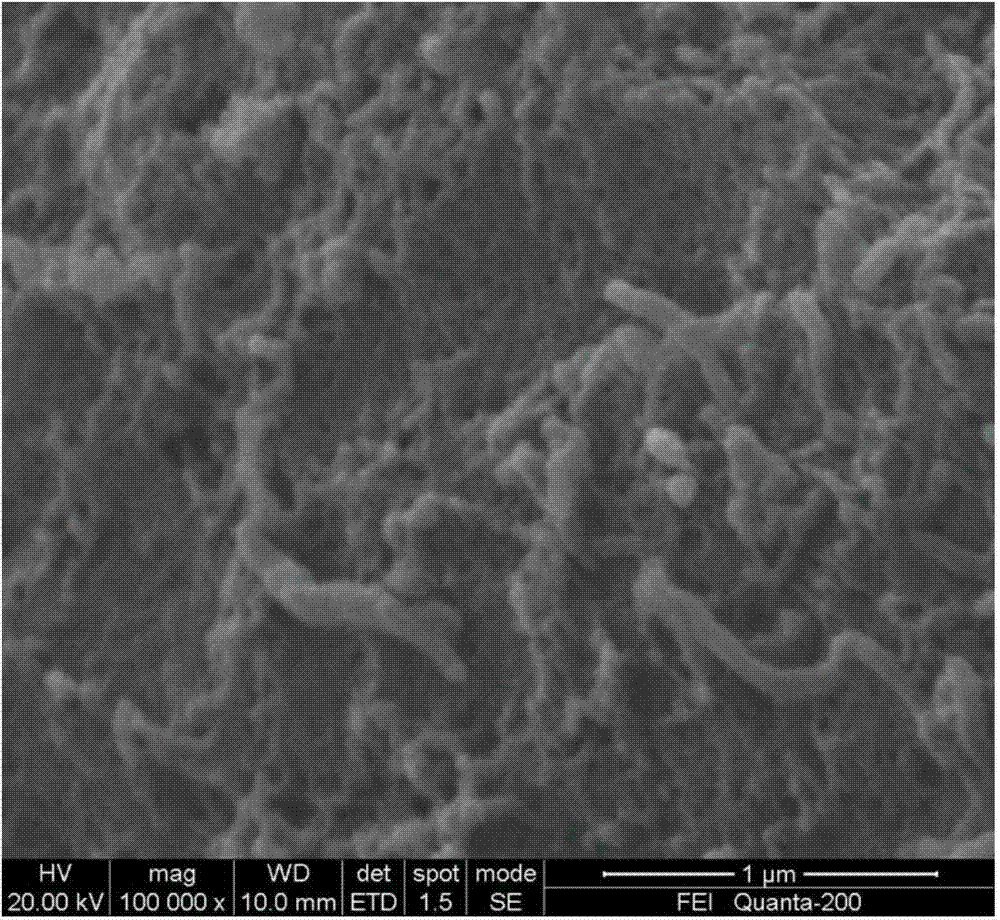

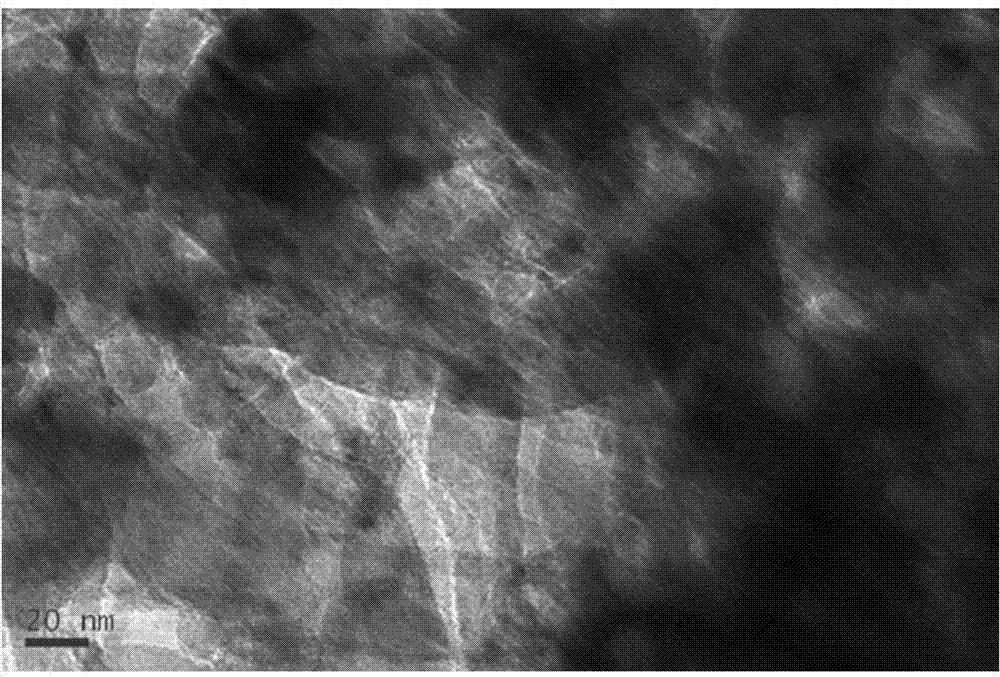

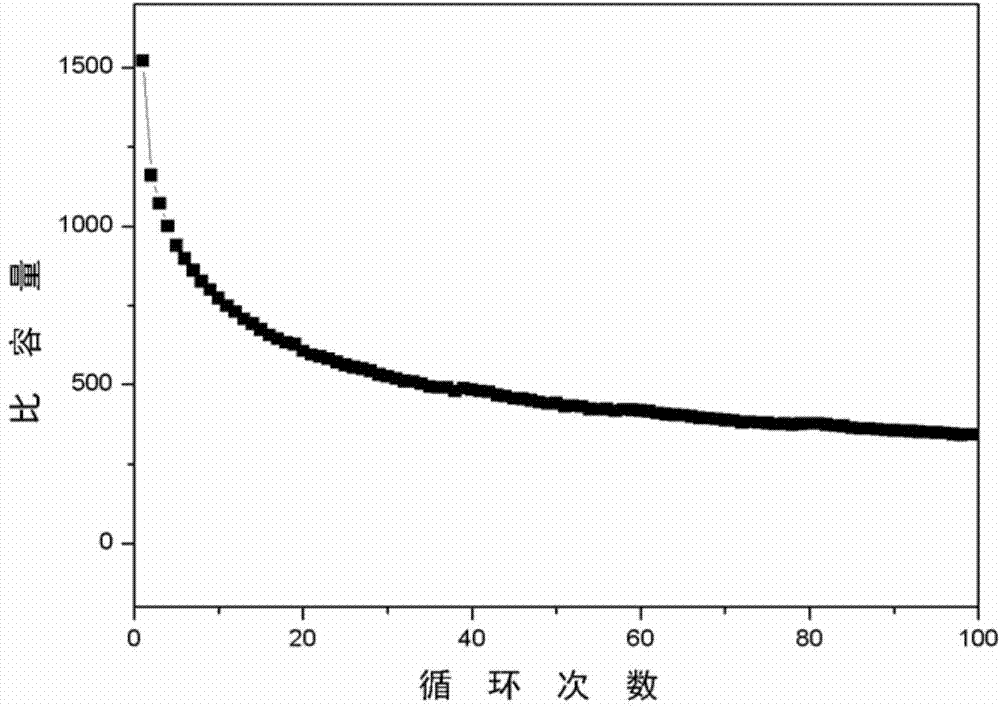

Embodiment 1

[0030] 1.046g Zn(NO 3 ) 2 4H 2 O and 0.432g terphenyl terephthalic acid are added to 30mL organic solvent dimethylformamide (DMF), and a certain amount of surfactant polyethylene glycol (PEG) is added thereto, and the surfactant polyethylene glycol (PEG ) accounted for 1% by weight of the precursor solution, and a certain amount of multi-walled carbon nanotubes was added to it, and the weight ratio of multi-walled carbon nanotubes to the multi-walled carbon nanotube-embedded mesoporous metal-organic framework composite material was 5%. The reaction precursor solution was isolated from the air and ultrasonically treated for 0.5h. After the precursor solution was mixed evenly, the precursor solution was transferred to a polytetrafluoroethylene-lined reactor by solvothermal method; the solution was heated from room temperature at 10°C / min Heated to 155°C and kept for 48 hours; after the solution was cooled to room temperature, the crystals were washed with dimethylformamide (D...

Embodiment 2

[0034] 1.668g Zn(NO 3 ) 2 ·6H 2 O and 0.222g of terephthalic acid are added to 30mL of organic solvent dimethylformamide (DMF), and a certain amount of surfactant polyethylene glycol (PEG) is added to it, and the surfactant polyethylene glycol (PEG) The amount of adding accounted for 2% by weight of the precursor solution, adding a certain amount of multi-walled carbon nanotubes to it, the amount of added multi-walled carbon nanotubes accounted for the weight of the multi-walled carbon nanotubes inlaid mesoporous metal organic framework composite material The ratio is 5%. The reaction precursor solution was isolated from the air and ultrasonically treated for 0.5h. After the precursor solution was mixed evenly, the precursor solution was transferred to a polytetrafluoroethylene-lined reactor by solvothermal method; the solution was transferred from Heating at room temperature to 110°C and keeping it for 24 hours; after the solution was cooled to room temperature, the crysta...

Embodiment 3

[0036] 1.046g Zn(NO 3 ) 2 4H 2 O and 0.432g terphenyl terephthalic acid are added to 30mL organic solvent dimethylformamide (DMF), and a certain amount of surfactant polyethylene glycol (PEG) is added thereto, and the surfactant polyethylene glycol (PEG ) accounted for 1% by weight of the precursor solution, and a certain amount of multi-walled carbon nanotubes was added to it, and the amount of multi-walled carbon nanotubes accounted for 1% of the multi-walled carbon nanotube-embedded mesoporous metal-organic framework composite. 30% by weight. The reaction precursor solution was isolated from the air and ultrasonically treated for 0.5h. After the precursor solution was mixed evenly, the precursor solution was transferred to a polytetrafluoroethylene-lined reactor by solvothermal method; the solution was transferred from Heating at room temperature to 155°C and keeping it for 48 hours; after the solution was cooled to room temperature, the crystals were washed with dimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com