Battery anode, preparation method thereof and lithium ion battery using the same

A lithium-ion battery, cathode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of low charging upper limit voltage, unstable charging system, poor cycle performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

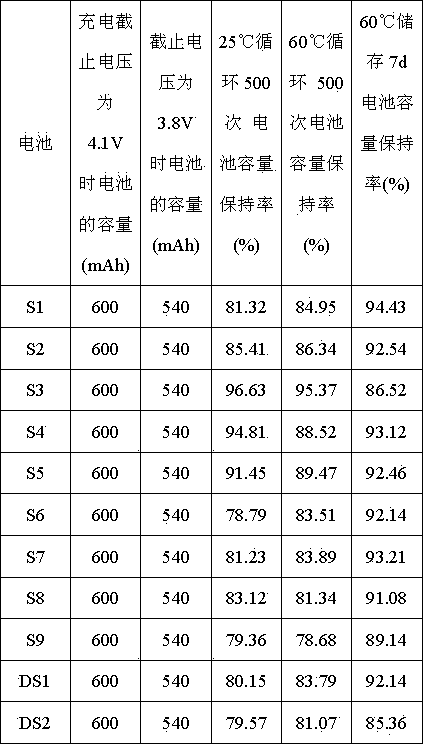

Examples

preparation example Construction

[0028] The preparation method of the negative electrode can adopt a conventional preparation method. For example, the negative electrode can be obtained by mixing the negative electrode material with a solvent, coating and / or filling on the conductive substrate, drying, and rolling or not rolling. Wherein, the solvent can be selected from N-methylpyrrolidone (NMP), dimethylformamide (DMF), diethylformamide (DEF), dimethylsulfoxide (DMSO), tetrahydrofuran (THF) and One or more of water and alcohol. The amount of the solvent can make the paste have viscosity and fluidity, and can be coated on the conductive substrate. Generally speaking, based on the weight of the negative electrode active material, the content of the solvent is 50-150% by weight, preferably 70-120% by weight. The content of the negative electrode active material and the binder is 40-70% by weight of the total weight of the negative electrode slurry, preferably 45-60% by weight. The amount of the solvent can ...

Embodiment 1

[0033] This example illustrates the positive electrode provided by the present invention, the lithium ion battery containing the positive electrode, and the preparation method thereof.

[0034] (1) Preparation of positive electrode

[0035] Mix and stir 100 g of N-methylpyrrolidone and 3 g of polyvinylidene fluoride until the viscosity of the mixture changes less than 3% within 10 minutes, and then add 3 g of microspherical superconducting carbon black with a particle size of 6.5 μm and stir. The viscosity of the mixed solution changed less than 3% within 10 minutes, and finally 90 grams of positive active material was added, wherein the positive active material contained 5 wt % of layered nickel cobalt lithium aluminate (the median particle size of the particles was 7.27 μm, D 10 =4.93μm,D 50 =7.27μm,D 90 = 11.03 μm) and 95 wt% olivine-type lithium ferrous phosphate (the median particle size is about 750 nm, D 10 =532nm, D 50 =750nm, D 90 =1030nm), stir for 2.5 hours unt...

Embodiment 2

[0042] This example illustrates the positive electrode provided by the present invention, the lithium ion battery containing the positive electrode, and the preparation method thereof.

[0043] The positive electrode slurry, battery positive electrode, negative electrode slurry, battery negative electrode and battery were prepared in the same manner as in Example 1, except that the positive electrode active material contained 8 wt % of layered nickel cobalt lithium aluminate and 92 wt % of olive Lithium ion secondary battery S2 is prepared by using stone-type lithium ferrous phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com