Multifunctional high and low temperature impulse testing box

An impact test chamber, high and low temperature technology, applied in laboratory appliances, program control in sequence/logic controllers, enclosures or chambers, etc., can solve the problems of high energy consumption, long debugging time, long adjustment time, etc. Achieve the effect of saving energy consumption, simple installation and operation, and easy online testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

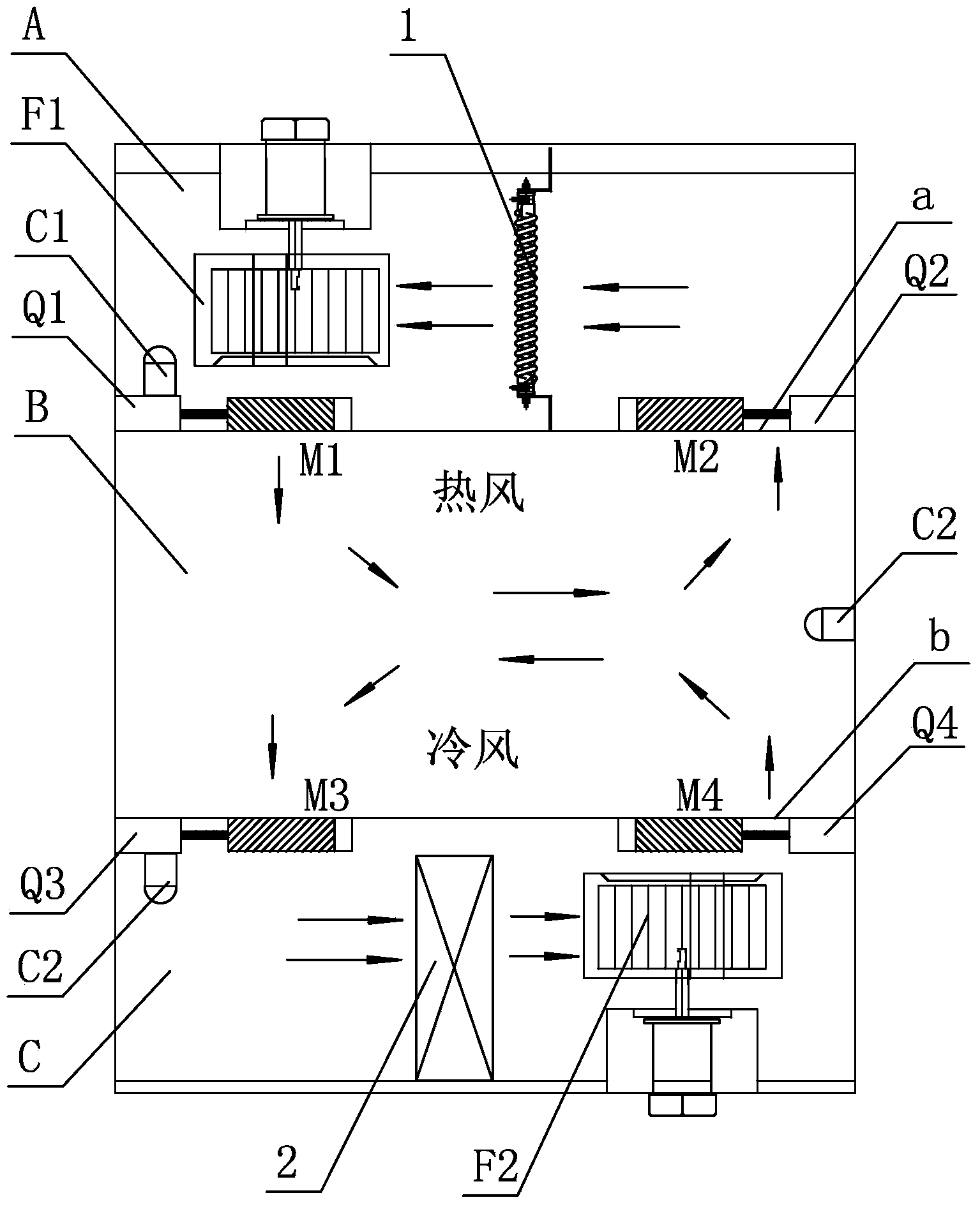

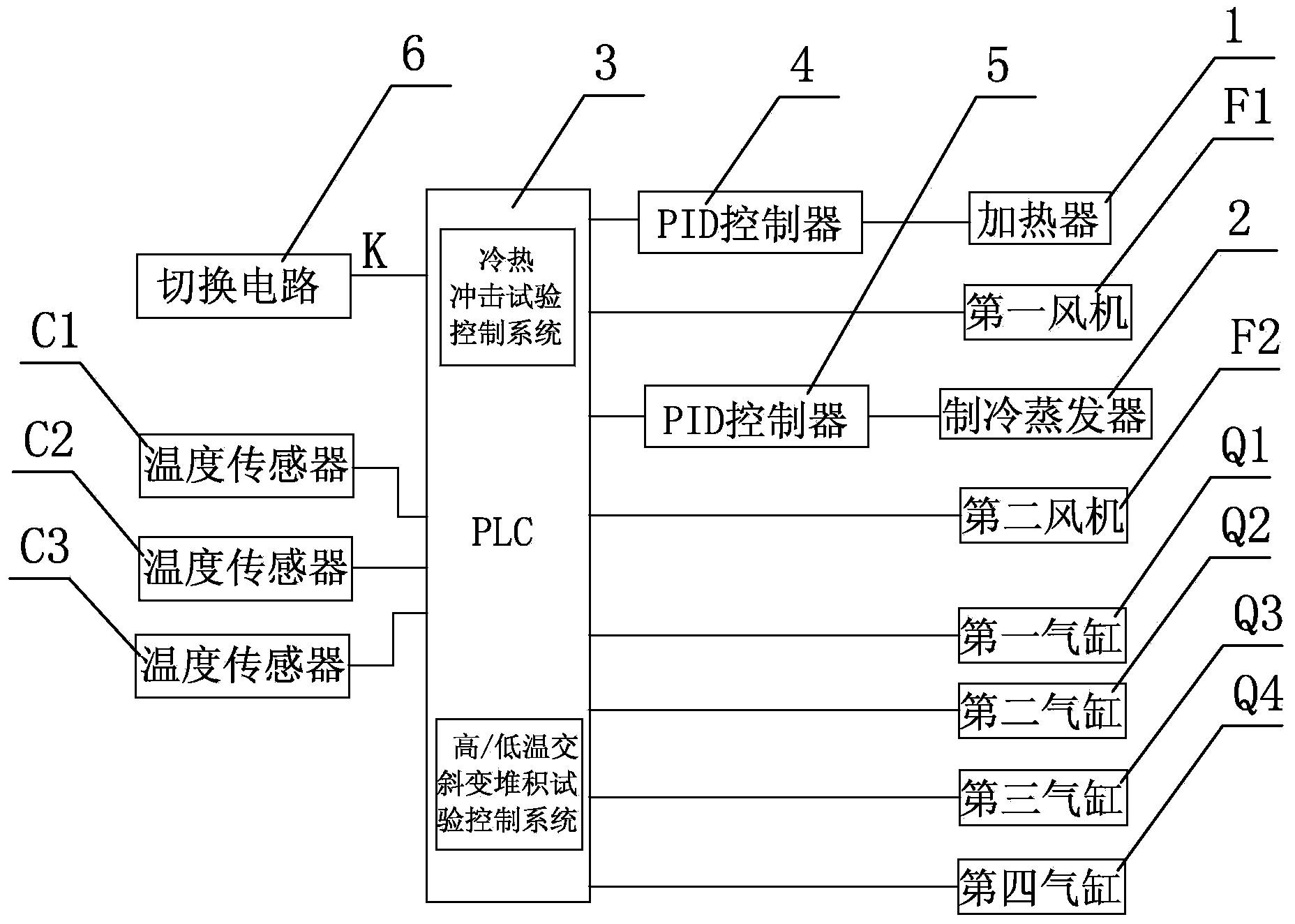

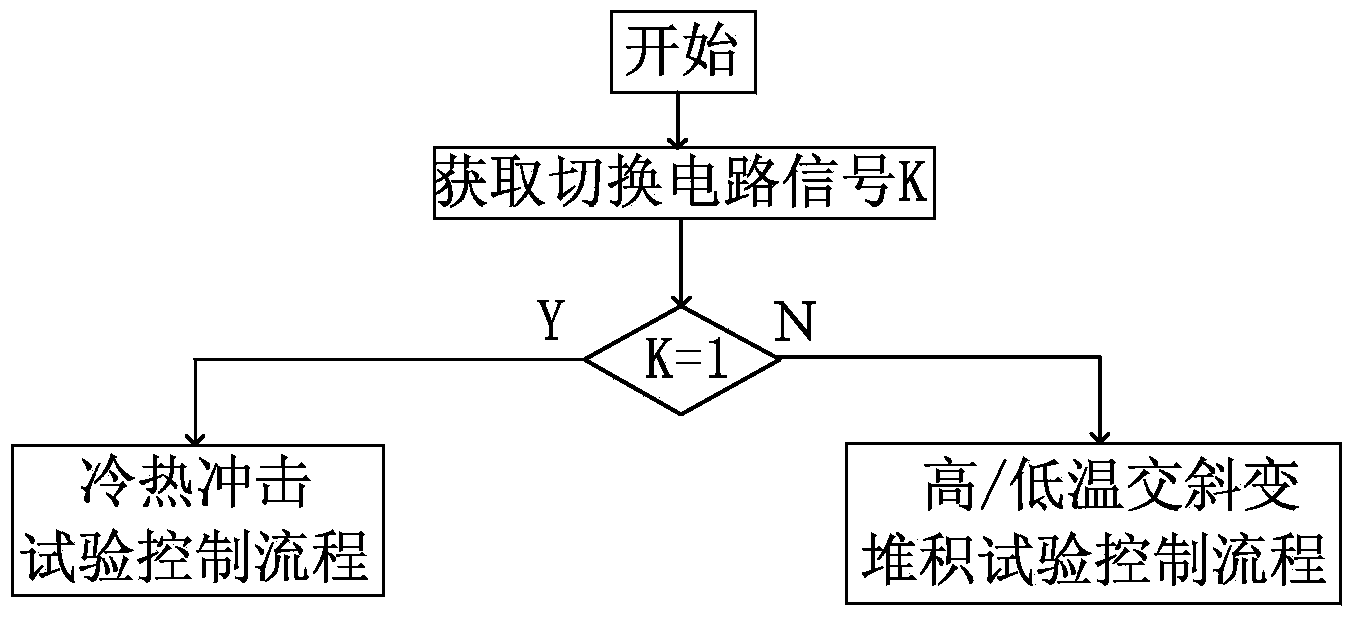

[0100] Such as figure 1 , 2 , 3, the present invention describes a multifunctional high and low temperature impact test chamber, which is composed of a heating zone A, a working zone B and a cooling zone C, and a heater 1 and a first fan F1 are arranged in the heating zone A, A refrigeration evaporator 2 and a second fan F2 are arranged in the cooling zone C, a first partition a is set between the heating zone A and the working zone B, and a second partition a is set between the cooling zone C and the working zone B. Two partitions b, one end of the first partition a is provided with a first damper M1, the other end of the first partition a is provided with a second damper M2, and one end of the second partition b is provided with a third damper M3, the other end of the second partition b is provided with a fourth damper M4, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com