Vacuum fireproof thermal-insulating and decorating integrated wall board

A fireproof insulation board, fireproof heat preservation technology, applied in the direction of covering/lining, building, building structure, etc., can solve the problems of the actual effect of heat preservation and heat insulation, the formation of cold and heat bridges, complex procedures and other problems, to achieve fireproof heat preservation and decorative effect Good, light and stable installation, different patterns and colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to express the present invention more clearly, the embodiments of the present invention will be further described below with reference to the accompanying drawings.

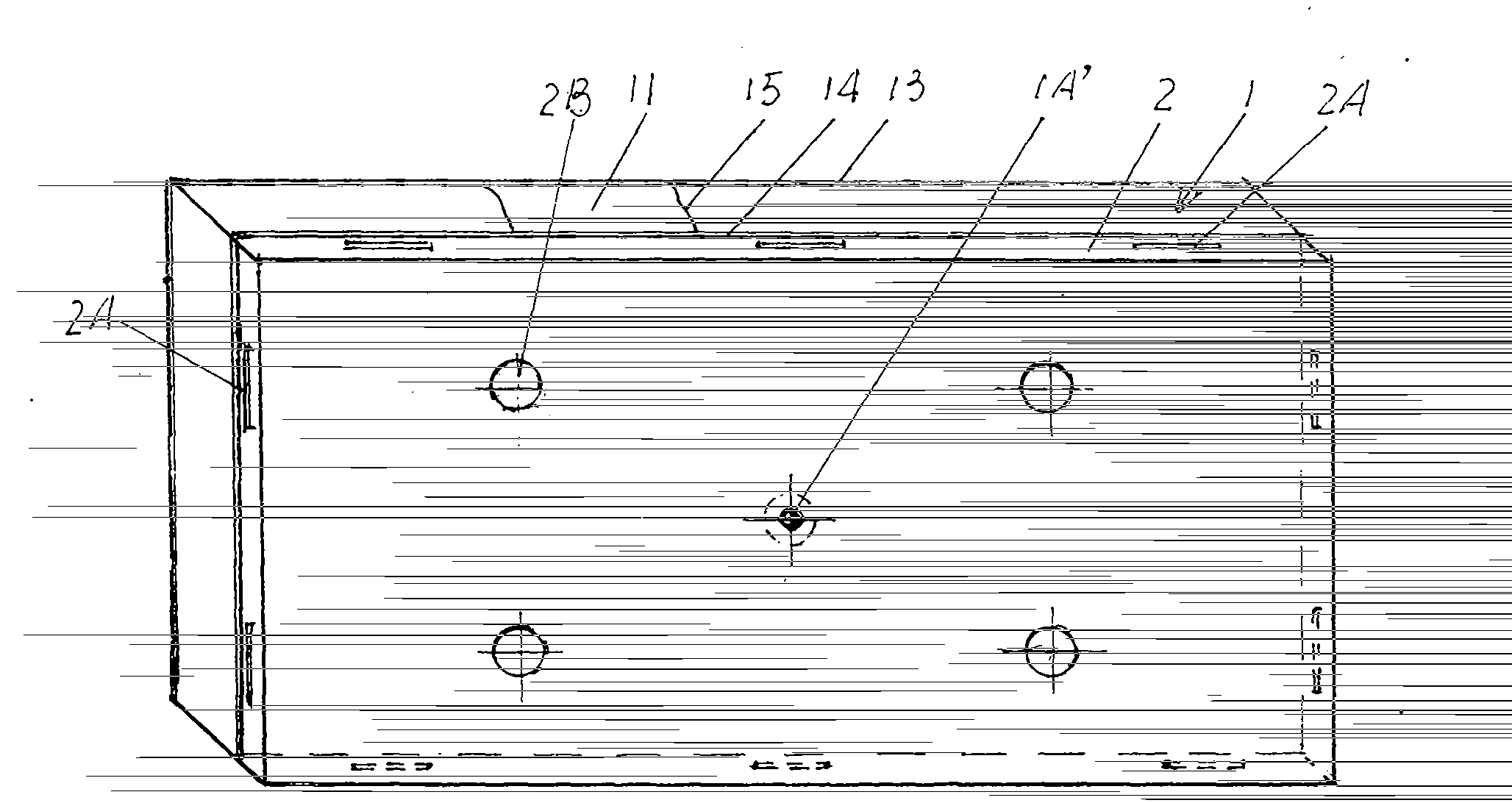

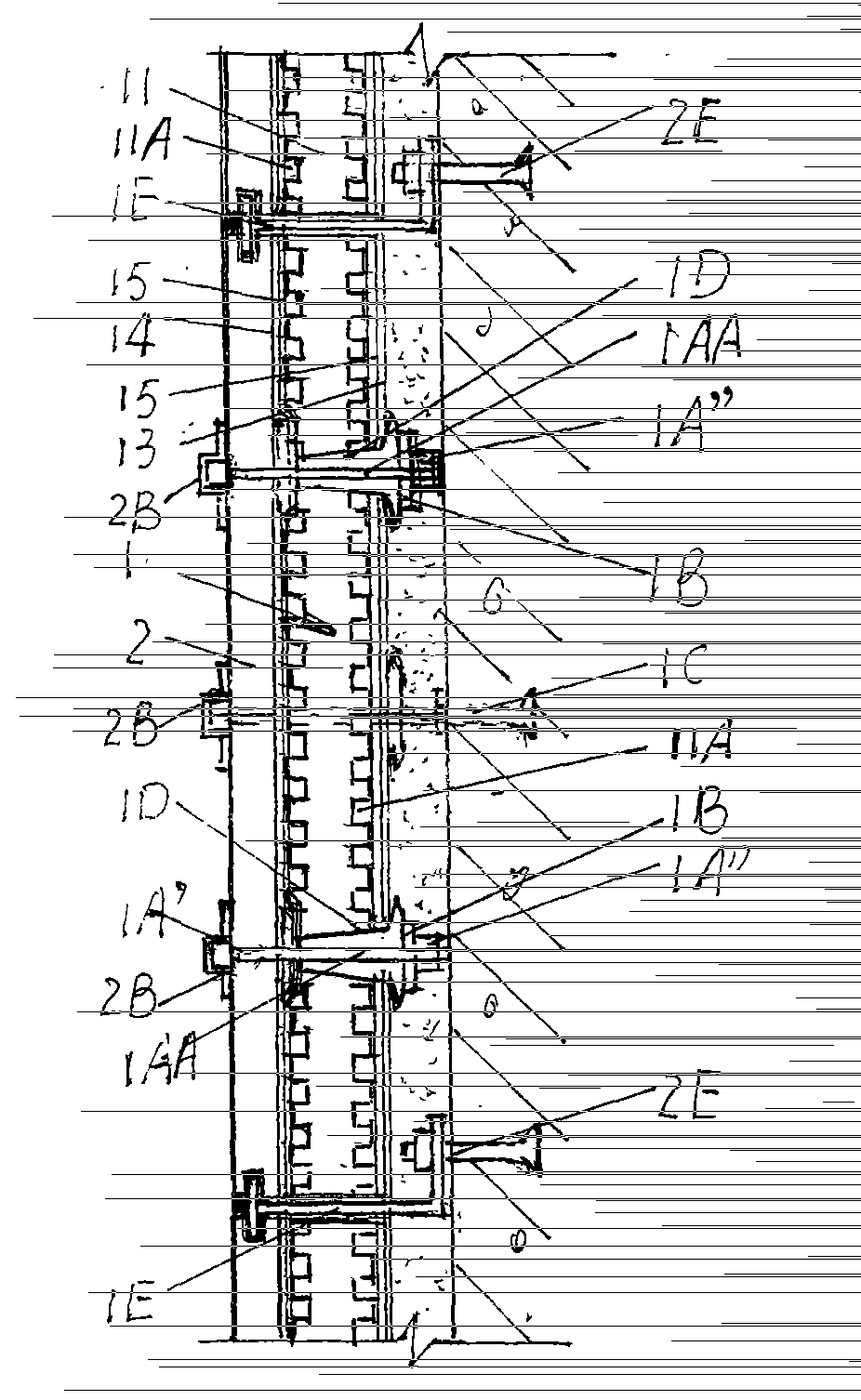

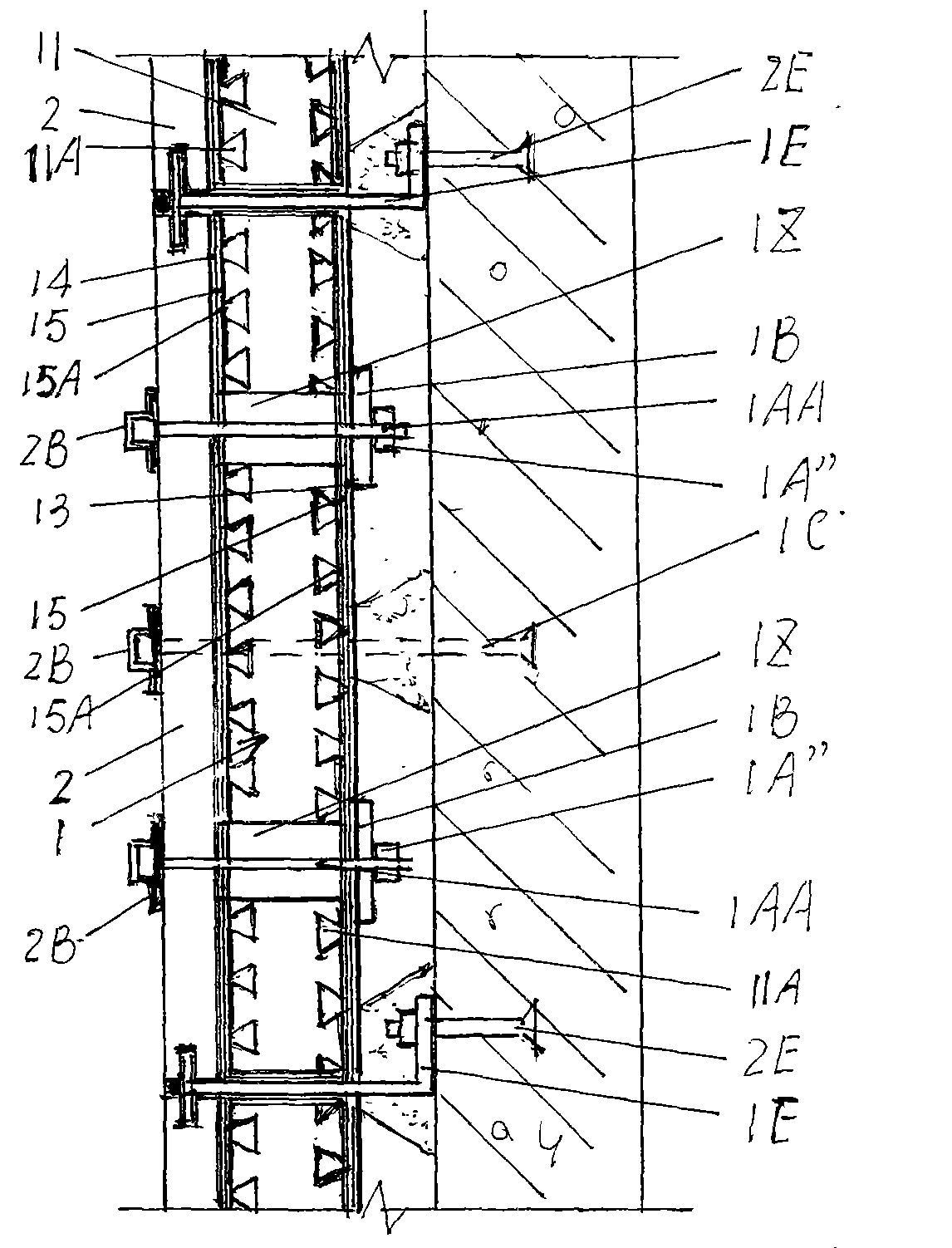

[0040] Example one of the present invention, such as Figure 1 ~ Figure 3 As shown, it is composed of a vacuum fireproof insulation board 1 and a surface veneer 2. The vacuum fireproof insulation board 1 is composed of a stuffy core insulation layer 11, a vacuum fireproof wrapping bag 15, an inner reflection layer 13 and an outer reflection layer 14. Or it is composed of a stuffy core insulation layer 11, a grid cloth 15A, a vacuum fireproof wrapping bag 15, an inner reflection layer 13 and an outer reflection layer 14; the grid cloth 15A is pasted on the stuffy core heat preservation The front and back sides of the layer 11; the vacuum fireproof insulation board 1 and the surface veneer 2 are fixed and composited as a whole by bolts.

[0041] Example two of the present invention, such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com