Grille type underground continuous wall construction outer mold and inner mold

An underground diaphragm wall and internal mold technology, which is applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of high bearing capacity requirements and complicated joints, and achieve high joint device strength, ensure continuity, and contact The effect of large compression and shear area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

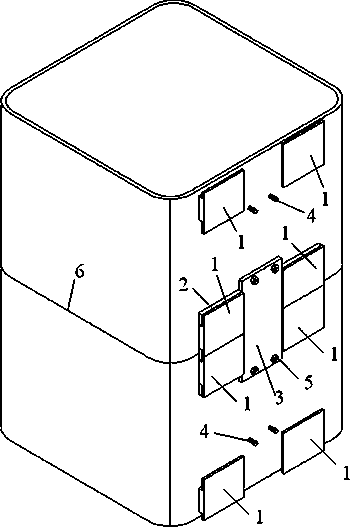

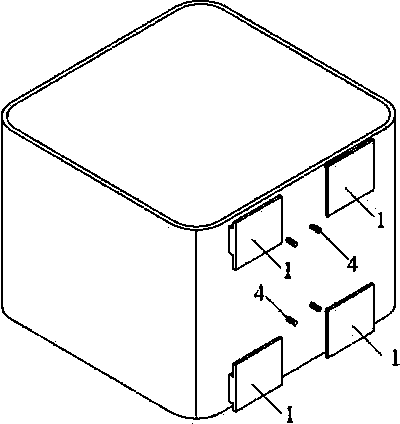

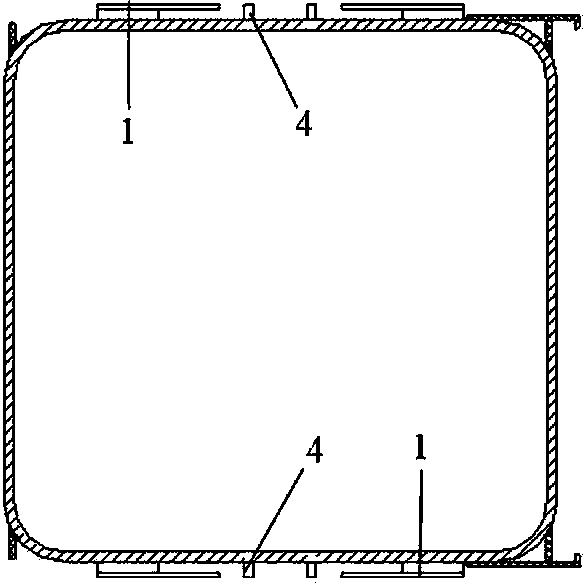

[0031] The present invention will be further described below in combination with the accompanying drawings (the guide rails are not drawn in all the three-dimensional drawings) and the embodiments.

[0032] The external formwork and internal formwork of the grid-type underground diaphragm wall of the present invention are mainly composed of three parts: a connecting plate assembly, clamps, fixed steel plates (including nuts) and screws.

[0033] The grid-type underground diaphragm wall construction external formwork of the present invention comprises a plurality of mouth-shaped outer molds arranged up and down, and a group of Connecting plate assembly, each group of connecting plate assemblies includes two symmetrically arranged connecting plates 1, the connecting plate 1 includes an outer plate 11 and an inner plate 12 arranged on the outer plate 11, the inner plate 12 is fixedly connected with the mouth-shaped outer mold, and the outer plate The longitudinal dimension of 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com