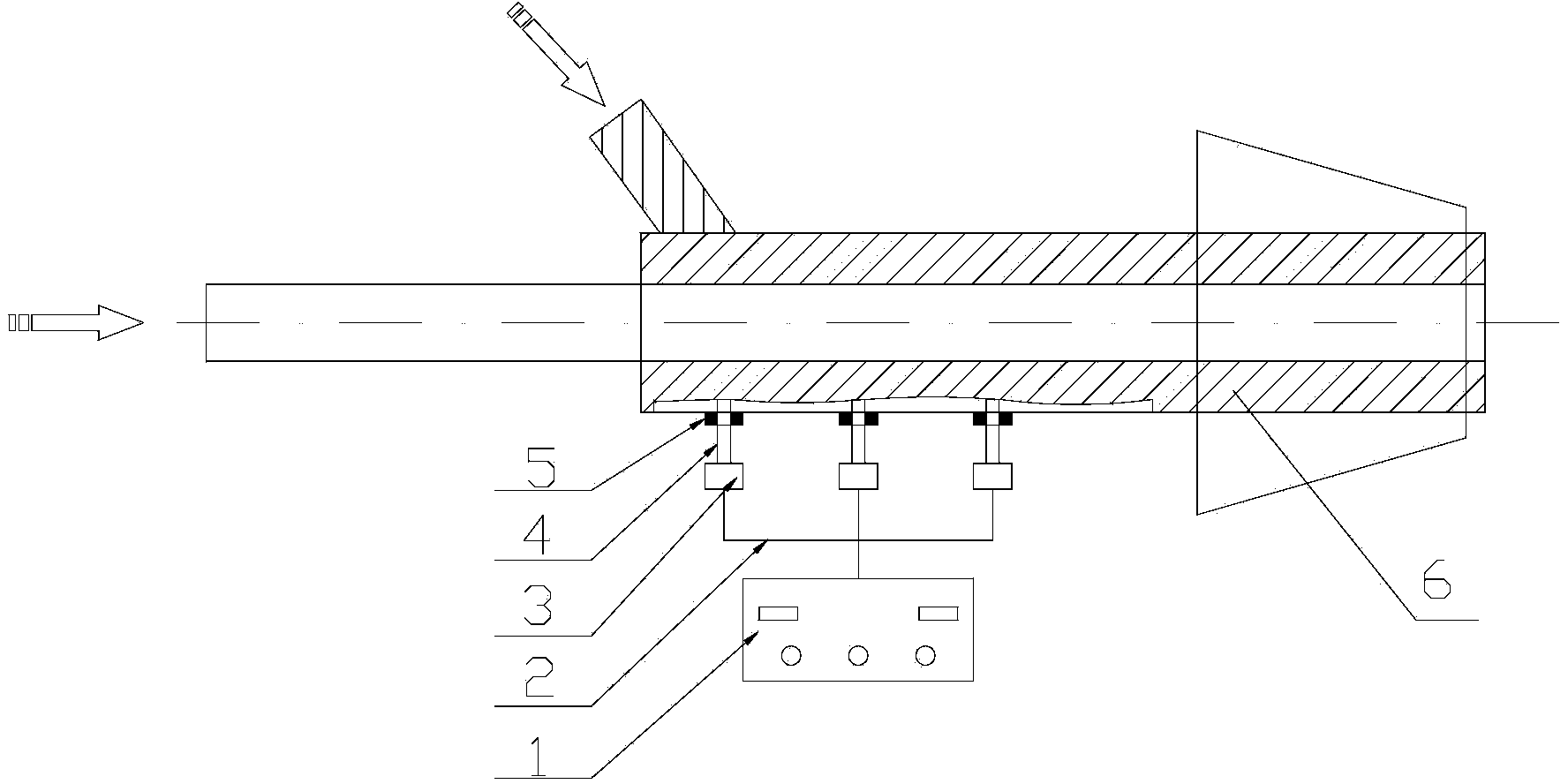

Device and method for preventing blockage of spray gun coke oven gas pipe of blast furnace

A technology of gas pipes and spray guns, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as pipeline blockages, and achieve the effects of preventing blockages, simple devices, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

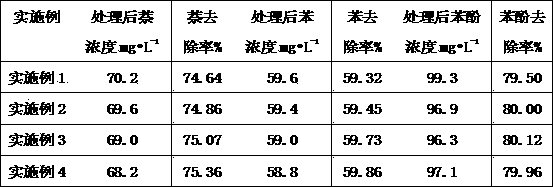

Embodiment 1

[0028] Insert an ultrasonic probe 4 with a diameter of 8 mm into the coke oven gas pipe 6 of the spray gun at 10 mm. The ultrasonic generator 1 sends a 30 kHz high-frequency signal, and the output ultrasonic electric power is 50 W. The ultrasonic transducer 3 is adjusted to a resonance state. The ultrasonic generator 1 Turn on once every 30 minutes, and run for 15 minutes each time.

Embodiment 2

[0030] Insert the ultrasonic probe 4 with a diameter of 10mm into the coke oven gas pipe 6 of the spray gun at 6mm, and the ultrasonic generator 1 sends out a 40kHz high-frequency signal, and the output ultrasonic electric power is 150W, and is adjusted to the resonance state by the ultrasonic transducer 3, and the ultrasonic generator 1 Turn on once every 25 minutes, and run for 10 minutes each time.

Embodiment 3

[0032] Insert the ultrasonic probe 4 with a diameter of 8mm into the coke oven gas pipe 6 of the spray gun at 15mm, and the ultrasonic generator 1 sends out a 40kHz high-frequency signal, and the output ultrasonic electric power is 150W, which is adjusted to resonance by the ultrasonic transducer 3

[0033] state, the ultrasonic generator 1 is turned on every 28 minutes, and runs for 15 minutes each time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com