Combined treatment method of N, N-dimethylformamide (DMF) wastewater

A technology of dimethylformamide and a treatment method is applied in the field of environmental protection water pollution control, can solve the problems of low efficiency, difficult regeneration, secondary pollution and the like, and achieves the effects of economical treatment, avoiding secondary pollution and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

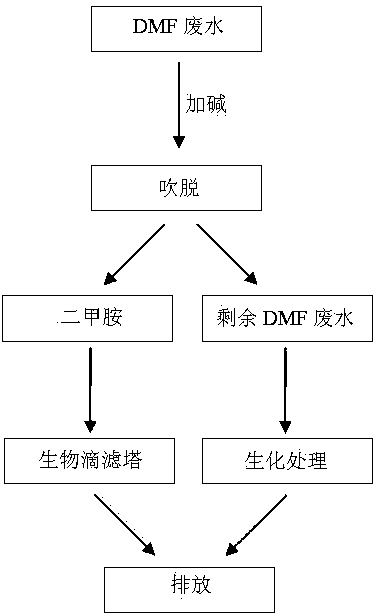

Method used

Image

Examples

Embodiment 1

[0028] 1. Take a certain volume of DMF wastewater, add 10g / L sodium hydroxide and enter the stripping tower, control the gas-liquid ratio to 1000:1, the reaction temperature is 25°C, the stripping reaction time is 1h, measure the TOC and DMF concentration, the experimental results are as follows:

[0029] project DMF (mg / L) TOC (mg / L) B / C Before blowing off 30186 28400 0.12 After blow off 16832 20500 0.34

[0030] 2. Biological trickling method: the residence time of dimethylamine gas in the tower is 60s, and the spray density of the spray liquid is 0.2m 3 / m 2 d, the reaction temperature is 25°C, air is introduced, and the device is operated for a period of time until the device is stable, and the concentration of dimethylamine at the inlet and outlet of the biological trickling filter is measured. The specific experimental results are as follows:

[0031] project Dimethylamine (mg / L) TOC (mg / L) before processing 985 ...

Embodiment 2

[0035] 1. Take a certain volume of DMF wastewater, add 20g / L sodium hydroxide and enter the stripping tower, control the gas-liquid ratio to 2000:1, the reaction temperature is 35°C, the stripping reaction time is 1.5h, measure the TOC of the wastewater before and after stripping and DMF concentration, the experimental results are as follows:

[0036] project DMF (mg / L) TOC (mg / L) B / C Before blowing off 30186 28400 0.12 After blow off 13510 16100 0.36

[0037] 2. Biological trickling method: the residence time of dimethylamine gas in the tower is 30s, and the spray density of the spray liquid is 0.25m 3 / m 2 d, the reaction temperature is 25°C, air is introduced, and the device is operated for a period of time until the device is stable, and the concentration of dimethylamine at the inlet and outlet of the biological trickling filter is measured. The specific experimental results are as follows:

[0038] project Dimethylamine (...

Embodiment 3

[0042] 1. Take a certain volume of DMF wastewater, add 30g / L sodium hydroxide and enter the stripping tower, control the gas-liquid ratio to 3000:1, the reaction temperature is 40°C, the stripping reaction time is 2h, measure the TOC and DMF concentration, the experimental results are as follows:

[0043] project DMF (mg / L) TOC (mg / L) B / C Before blowing off 30186 28400 0.12 After blow off 6737 14200 0.39

[0044] 2. Biological trickling method: the residence time of dimethylamine gas in the tower is 50s, and the spray density of the spray liquid is 0.2m 3 / m 2 d, the reaction temperature is 25°C, air is introduced, and the device is operated for a period of time until the device is stable, and the concentration of dimethylamine at the inlet and outlet of the biological trickling filter is measured. The specific experimental results are as follows:

[0045] project Dimethylamine (mg / L) TOC (mg / L) before processing 932 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com