Hole boring device

A boring and blind hole technology, applied in the direction of boring bars, turning equipment, tool holder accessories, etc., can solve the problems of easy vibration of the tool bar, decline in workpiece quality, chipping, etc., to achieve less vibration, increased strength, and reduced The effect of the broken knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

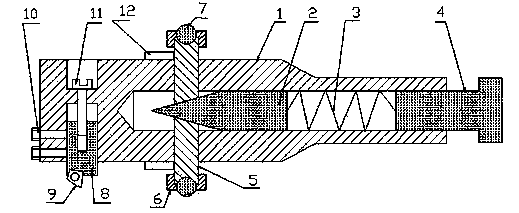

[0010] In the figure, this kind of boring device includes a cutter bar 1, a cone head rod 2, a spring 3, a top wire 4, a support column 5, a flange cap 6, a steel ball 7, a cutter seat 8, a cutter head 9, a bolt 10, an adjustment Screw mandrel 11, spring leaf 12, described a kind of boring device is provided with taper head rod 2 in the middle blind hole inner end of cutter bar 1 afterbody, and the front end of taper head rod 2 is a conical structure, and at cutter bar 1 waist A support column 5 is symmetrically installed on the top of the support column 5. The inner end of the support column 5 is a bevel-shaped structure. Vertical, the upper and lower ends of the support column 5 are respectively fixed with a steel ball 7 through the flange cap 6, and a spring leaf 12 is respectively fixedly installed on the knife bar 1 on the side of the support column 5, and one end of the spring leaf 12 is connected to the support column 5. The outer circle parts of the tool bar 1 are sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com