Shockproof packaging box of optical splitter

An optical splitter and packaging box technology, applied in the fiber mechanical structure and other directions, can solve the problems of the steel pipe and the packaging box falling off, the impact force is large, and it is easy to make mistakes, so as to avoid pulling or breaking the optical fiber and reducing the impact. strength and damage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

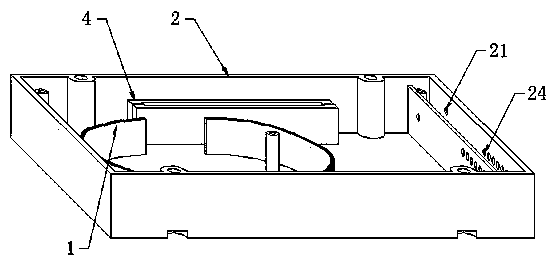

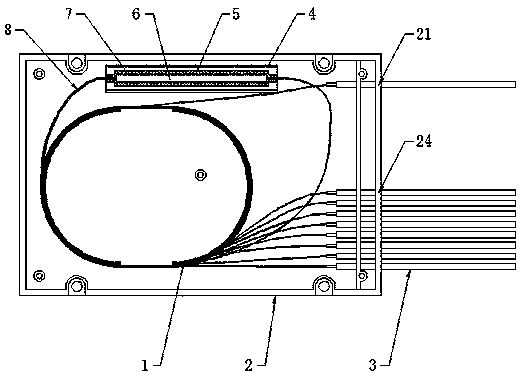

[0050] Such as Figure 1-2 As shown, the present invention creates a shockproof packaging box for an optical splitter, which includes a packaging box 2, an optical fiber inlet hole 21 is provided on the right end surface of the packaging box 2, and a row of optical fiber outlet holes 24 is provided on the right end surface of the packaging box 2; An optical fiber protection device 1 is provided at the center of the inner surface of the packaging box 2, and a mounting seat 4 is provided on the inner surface of the packaging box 2 near the optical fiber inlet hole 21. The mounting seat 4 is equipped with a steel pipe sleeve 5, and the steel pipe sleeve 5 A buffer and shockproof layer 7 is arranged between the interior and the planar optical waveguide splitter 6;

[0051] In actual use, such as figure 2 As shown, a single optical fiber is introduced from the optical fiber inlet hole 21, first wound around the optical fiber protection device 1, and then connected to the planar o...

Embodiment 2

[0054] In a preferred implementation situation, with respect to Example 1, such as Figure 3-5 As shown, the internal structure of the mounting seat 4 is vase-shaped, the size of the opening end of the upper end of the vase-shaped upper end is larger than the size of the bottom end, the upper end of the internal shape is an outer convex arc surface I41, and the middle section is an inner concave arc surface 42 , the bottom section is the convex arc surface II43; the outer shape of the above-mentioned steel pipe sleeve 5 is the convex arc surface III51, and the arc degree of the convex arc surface III51 and the concave arc surface 42 are kept co-operate.

[0055] In actual use, the steel pipe sleeve 5 needs to be installed in the inner cavity of the mounting base 4 . During the installation process, the outer convex arc surface III51 of the steel pipe sleeve 5 first contacts the outer convex arc surface I41 on the upper part of the mounting seat 4. Through extrusion, the inner...

Embodiment 3

[0058] In a preferred implementation situation, with respect to embodiment 2, such as Figure 6-8 As shown, the mounting base 4 is provided with more than three cover mounting bases 44 for mounting the cover plate 9, the width b of the above cover plate 9 is 6-10 mm, and the above cover plate 9 includes The rotating end 91 and the fixed end 93; the above-mentioned rotating end 91 is hinged with the cover mounting seat 44 through the rotating shaft 92, and the cross section of the rotating end 91 is arc-shaped; the above-mentioned fixed end 93 lower surface is installed with a The thimble 94 is used to rigidly fix the fixed end 93 , and the mounting base 4 is provided with a slot 45 matched with the thimble 94 .

[0059] The technical problem to be solved in Embodiment 3 is: the steel pipe sleeve 5 can be further tightened by providing the cover plate mounting seat 44 for installing the cover plate 9, so that the steel pipe sleeve 5 cannot be displaced regardless of the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com