Helical gear heading mold

A helical gear and upsetting technology, which is applied in the manufacture of tools, wheels, forging/pressing/hammering machinery, etc., can solve the problems of high manufacturing cost of helical gears, long processing cycle of helical gears, low processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

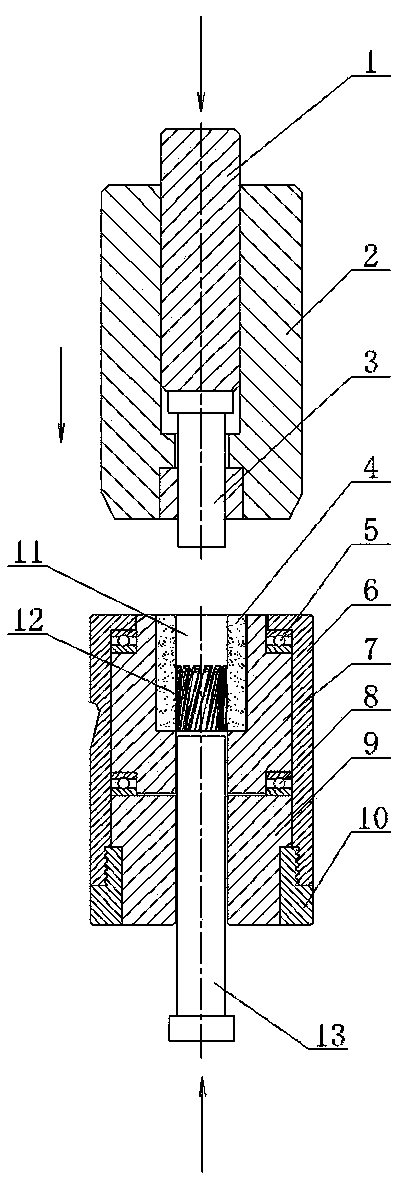

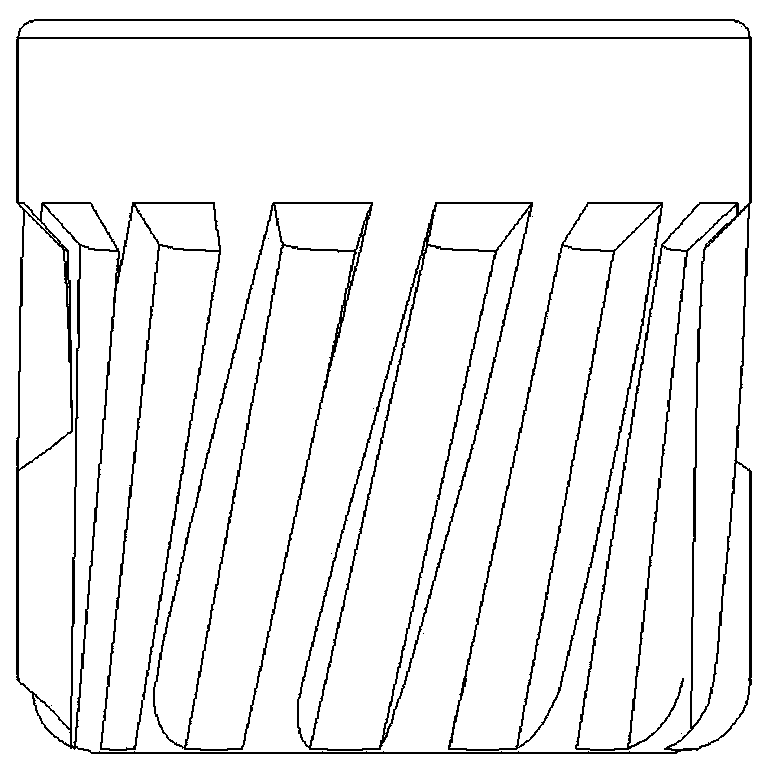

[0010] like figure 1 As shown, the helical gear upsetting mold of the present invention is composed of an upper die and a lower die, and the upper die includes an upper die cover 2 and a punch 3, and the punch 3 is movable up and down in the inner hole of the upper die cover 2, punching The top of the head 3 is provided with a push rod 1; the lower mold includes a lower mold cover and a rotary mold body 7, the lower mold cover is screwed by an upper sleeve 6 and a lower sleeve 10, and the rotary mold body 7 passes through the upper The plane bearing 5 and the lower plane bearing 8 are rotatably arranged in the inner cavity of the lower mold sleeve, the upper end surface of the upper plane bearing 5 is supported on the end surface of the inner hole of the upper sleeve 6, and the lower end surface of the lower plane bearing 8 is supported on the pad mold 9, The cushion mold 9 is fixed in the upper mold sleeve when the upper and lower sleeves are screwed tightly, and the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com