Mechanical arm

A technology of manipulators and racks, applied in manipulators, program-controlled manipulators, metal processing equipment, etc., can solve problems such as many defective products, low production efficiency, and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

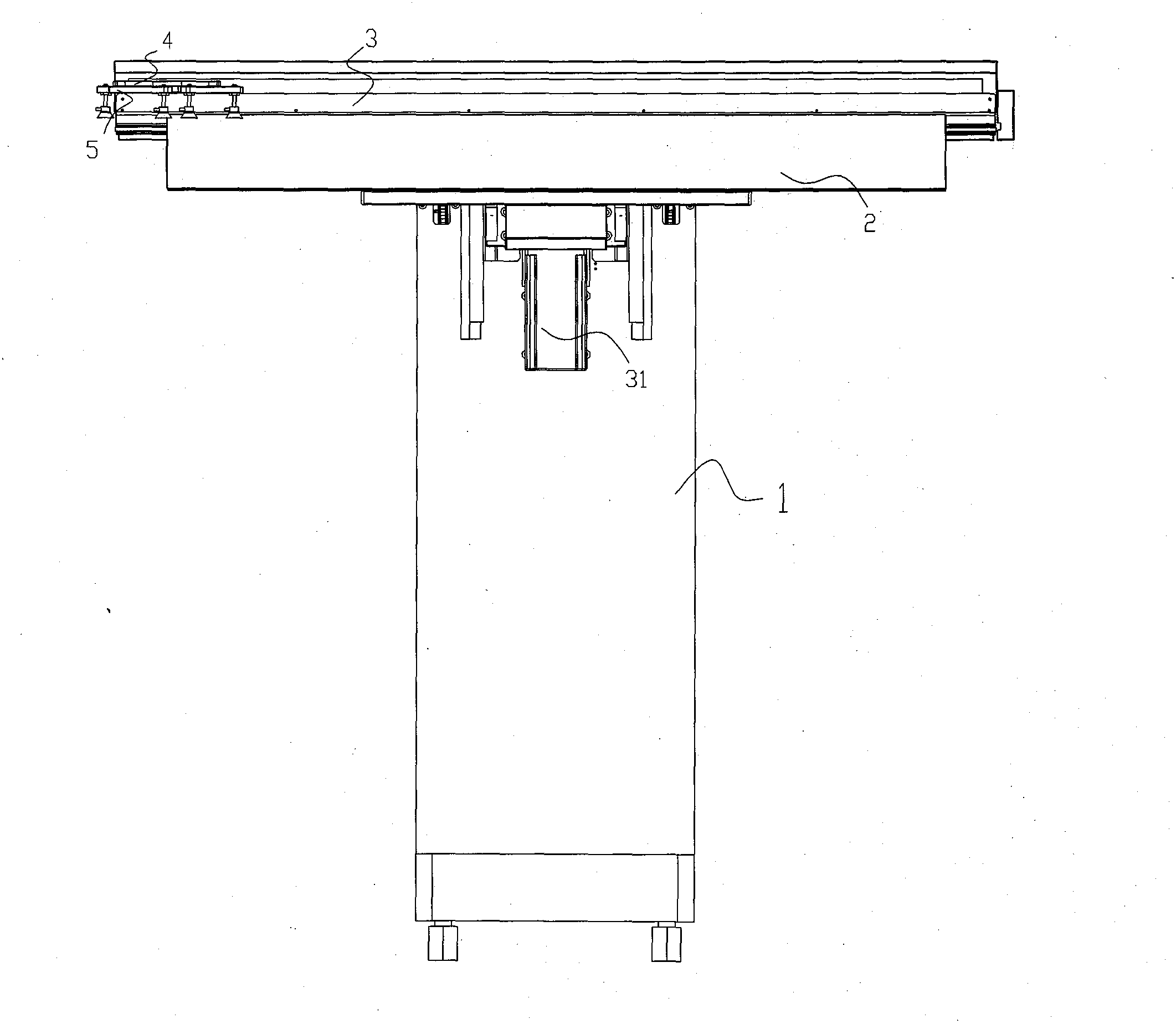

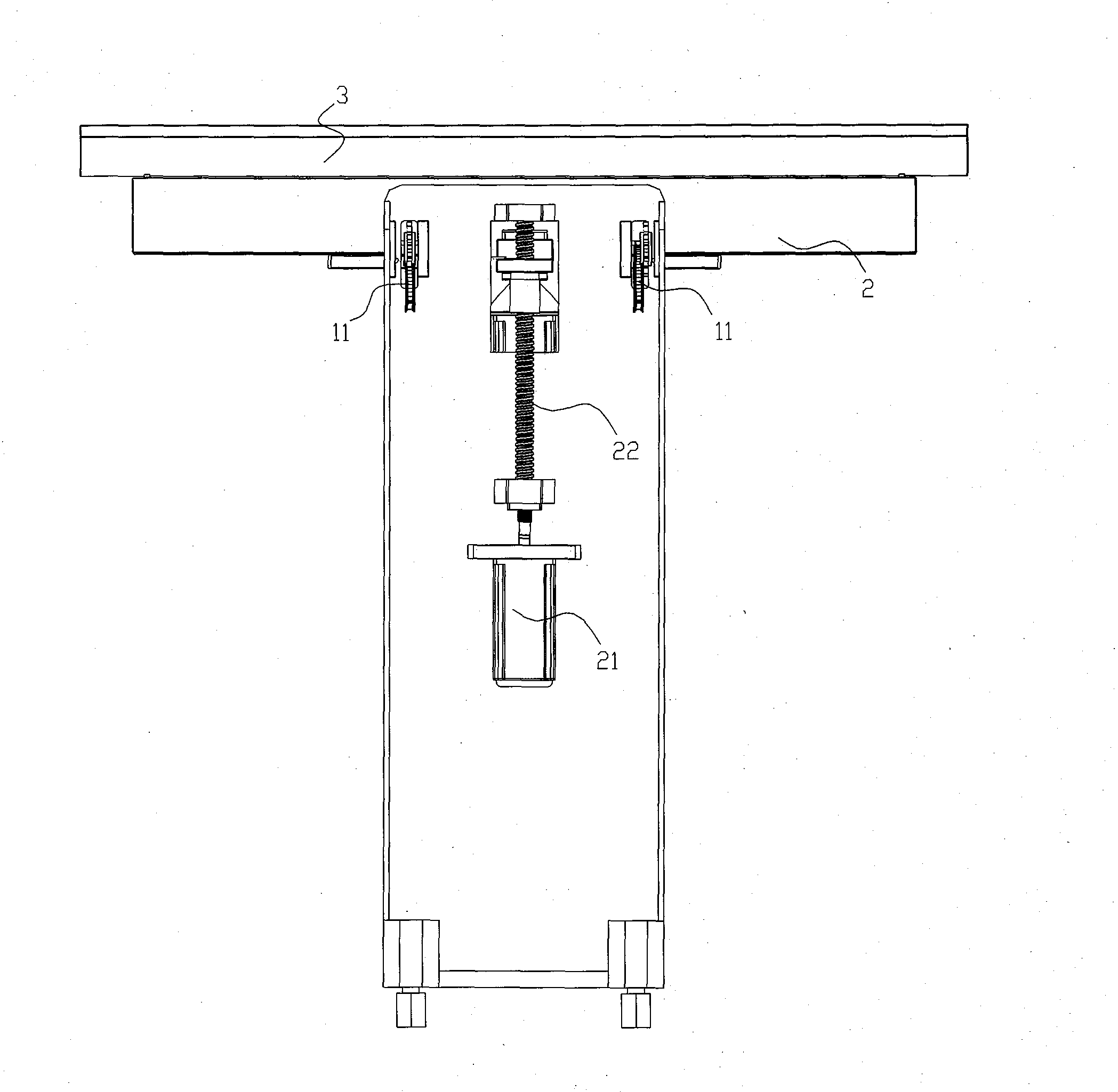

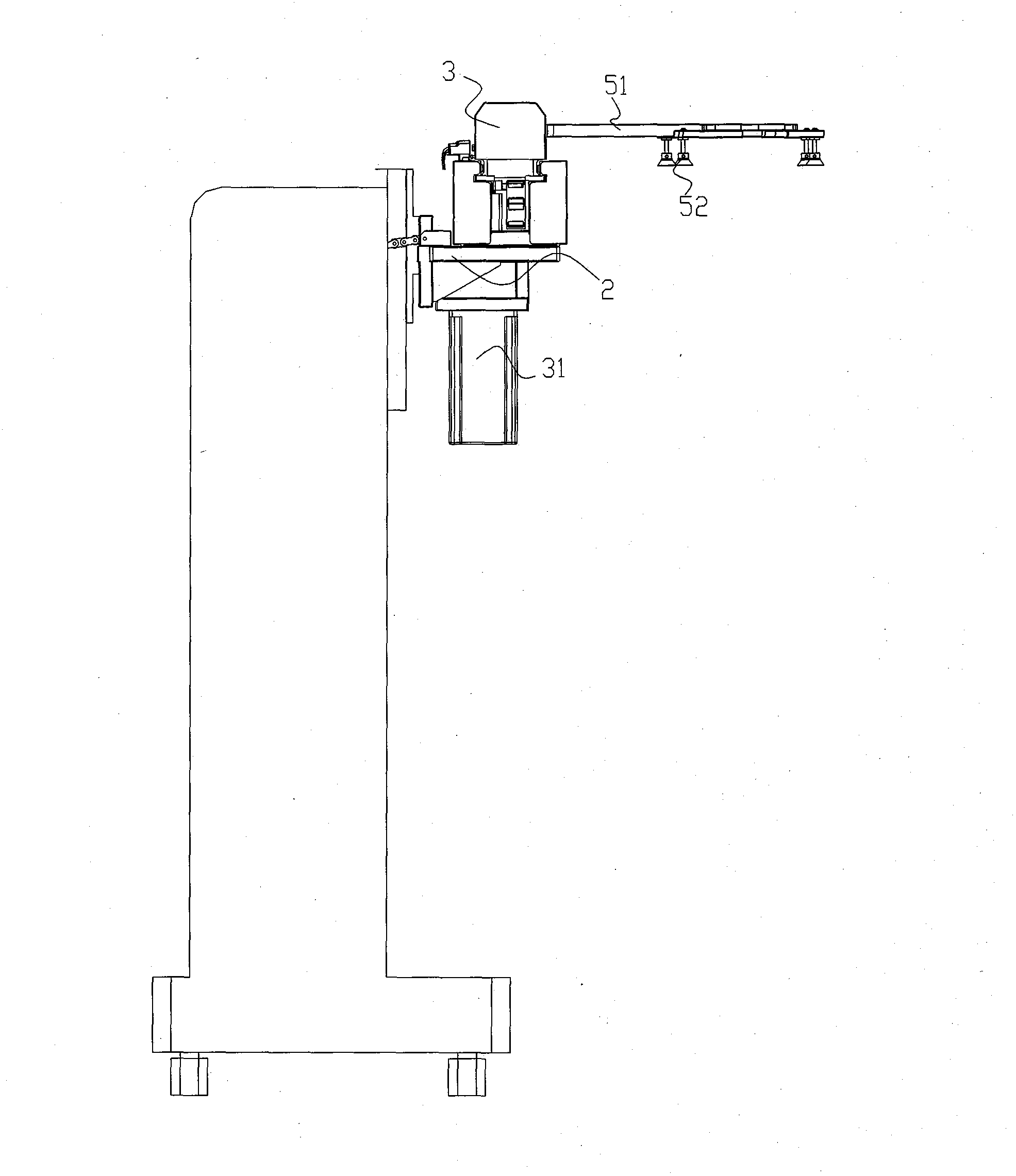

[0024] like figure 1 and 2 As shown, a manipulator according to a specific embodiment of the present invention includes a frame 1 as a base, a Z-axis motion assembly that can move up and down on the frame 1, and a Z-axis motion assembly that can move left and right. The X-axis motion component and the gripper 5 arranged on the X-axis motion component. The manipulator achieves the technical purpose of automatically grabbing and displacing objects through the up, down, left, and right movements of the Z-axis action component and the X-axis action component.

[0025] The Z-axis action assembly in this specific embodiment, figure 2 The display is relatively comprehensive, mainly composed of a Z-axis guide rail, a Z-axis slider 2 mounted on the guide rail and sliding along the guide rail, and a Z-axis servo motor 21 installed on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com