Processing method for increasing usability of burley tobacco

A processing method and technology of burley tobacco, applied in the fields of tobacco, application, and treatment of tobacco, can solve the problem of reducing the miscellaneous gas and irritation of burley tobacco, can not deal with the pungent feeling of burley tobacco, and can not effectively remove the smell of burley tobacco and other issues, to achieve the effect of improving the use value, significant effect and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add cold water into a stainless steel container and heat it with steam. When the water temperature reaches 85°C, add Burley tobacco. The weight ratio of Burley tobacco to water is 1:16. After soaking for 20 minutes, filter the Burley tobacco, add Luzhou-flavor 68° Wuliangye to the Burley tobacco leaves according to the solid-to-liquid ratio of 400:1, put it in a steamer, fumigate, and take out the Burley after 10 minutes Tobacco leaves are dried to a moisture content of 17-19%.

[0014] The obtained burley tobacco leaves are cut into uniform shredded tobacco on a shredding machine, and rolled into cigarettes for smoking evaluation according to the smoking evaluation requirements.

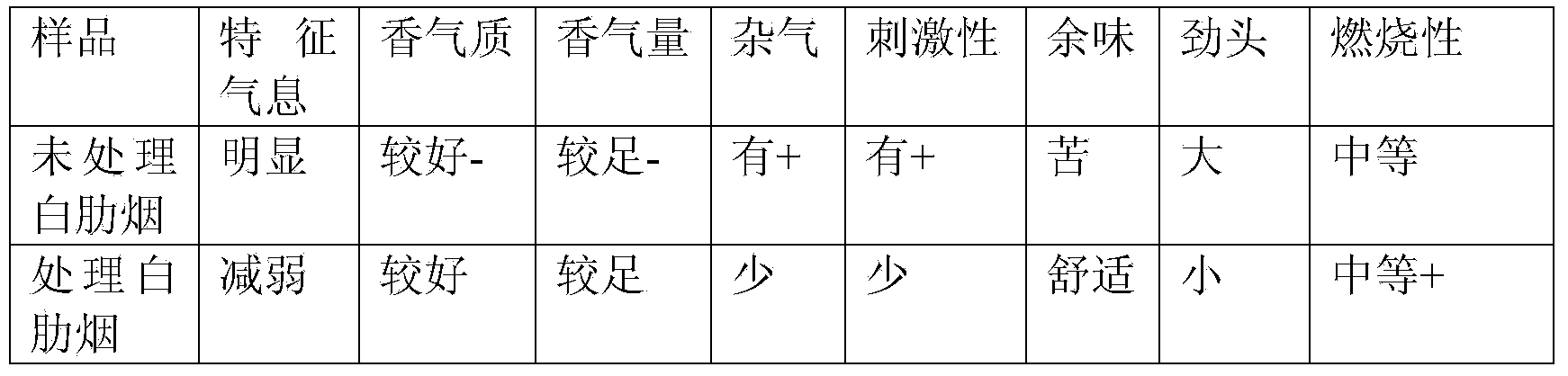

[0015] The results of the sensory evaluation and smoking evaluation of the samples showed that the smoke of the treated Burley tobacco was significantly weakened, the irritation of the burley tobacco was significantly reduced, the smoke was round, the taste was comfortable, and the aftertaste...

Embodiment 2

[0017] Add cold water into a stainless steel container and heat it with steam. When the water temperature reaches 85°C, add Burley tobacco. The weight ratio of Burley tobacco to water is 1:16. After soaking for 20 minutes, filter the Burley tobacco and add sauce-flavored 53° five-star Kweichow Moutai to the Burley tobacco leaves according to the weight ratio of solid-to-liquid ratio of 500:1, put it in a steamer, fumigate, and take it out after 10 minutes Burley tobacco leaves, dried to 17-19% moisture.

[0018] The obtained burley tobacco leaves are cut into uniform shredded tobacco on a shredding machine, and rolled into cigarettes for smoking evaluation according to the smoking evaluation requirements.

[0019] The results of sensory evaluation and smoking evaluation of the samples show that the irritating miscellaneous gas of the treated Burley tobacco is reduced, the smell of Burley tobacco is significantly weakened, the strength is reduced, the smoke is rich in aroma, an...

Embodiment 3

[0021] Add cold water into a stainless steel container and heat it with steam. When the water temperature reaches 95°C, add Burley tobacco. The weight ratio of Burley tobacco to water is 1:20. After soaking for 30 minutes, filter the Burley tobacco and add 53° Thirty Years Blue and White Porcelain Fen Wine to the Burley tobacco leaves according to the solid-to-liquid ratio of 300:1 by weight, put it in a steamer, fumigate, and take out the Burley after 15 minutes Tobacco leaves are dried to a moisture content of 17-19%.

[0022] The obtained burley tobacco leaves are cut into uniform shredded tobacco on a shredding machine, and rolled into cigarettes for smoking evaluation according to the smoking evaluation requirements.

[0023] The results of the sensory evaluation and smoking evaluation of the sample show that the irritating miscellaneous gases of the treated Burley tobacco are significantly reduced, the smell of the Burley tobacco is obviously weakened, the strength is li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com