Preparation method of corn peptide glycosylation product nano particles embedding lipid-soluble vitamins

A technology of fat-soluble vitamins and nanoparticles, applied in food science, food forming, application, etc., can solve the problems of low bioavailability, achieve the effects of improving solubility, good transparency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

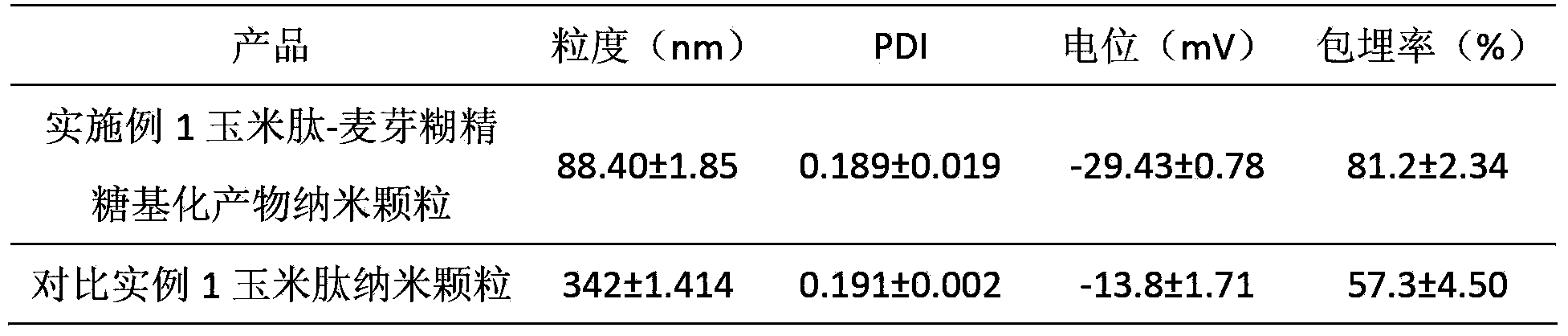

Embodiment 1

[0028] Dissolve 2g of corn peptide and 2g of maltodextrin in 20mL of 20mM, pH7.5 sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution, stir at 500rpm for 2h; / L sodium hydroxide to adjust the pH value to 7.5, stirred at 500rpm for 2h, and then freeze-dried; put the dry powder in a closed desiccator, and reacted for 4 days at a relative humidity of 79% and a temperature of 60°C; the obtained solid was dissolved in 40mL to In ionized water, stir at 500rpm for 2h, centrifuge at 10000rpm for 15min, take the supernatant, freeze-dry, and store the dried powder in a refrigerator at 4°C to obtain corn peptide‐maltodextrin glycosylation products, wherein the mass ratio of corn peptide to maltodextrin is 1 :1.

[0029] Dissolve 80mg of corn peptide‐maltodextrin glycosylation product in 19.2mL of deionized water, stir at 500rpm for 1, adjust pH5 with 0.1mol / L hydrochloric acid; dissolve 20mg of vitamin E in 10mL of absolute ethanol, stir at 500rpm for 30min; take 0.8 ...

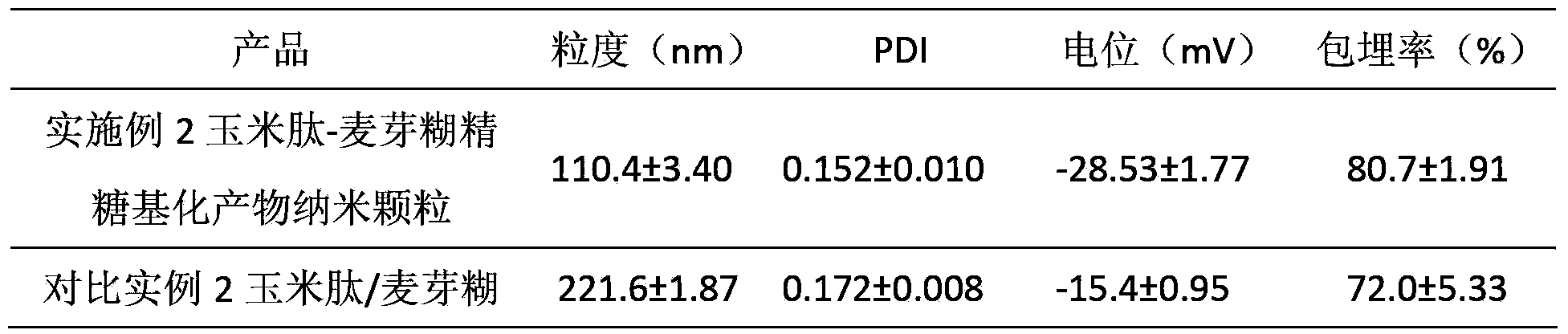

Embodiment 2

[0043] Dissolve 1 g of corn peptide and 1 g of maltodextrin in 20 mL of 10 mM, pH 7.5 sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution, stir at 500 rpm for 1 h; / L sodium hydroxide to adjust the pH to 7.5, stirred at 500rpm for 2h, and then freeze-dried; put the dry powder in a closed desiccator, and reacted for 5 days at a relative humidity of 79% and a temperature of 65°C; the obtained solid was dissolved in 20mL of deionized Stir in water at 500rpm for 2h, centrifuge at 10000rpm for 15min, take the supernatant and freeze-dry it, and store the dried powder in a refrigerator at 4°C to obtain corn peptide-maltodextrin glycosylation products, wherein the mass ratio of corn peptide to maltodextrin is 2:1.

[0044] Dissolve 120mg of corn peptide-maltodextrin glycosylation product in 19.0mL of deionized water, stir at 500rpm for 2h, adjust pH6 with 0.1mol / L sodium hydroxide; dissolve 50mg of vitamin D in 10mL of absolute ethanol, stir at 500rpm for 40min; Ta...

Embodiment 3

[0052] Dissolve 2g of corn peptide and 2g of maltodextrin in 20mL of 10mM, pH7.5 sodium dihydrogen phosphate-disodium hydrogen phosphate buffer, stir at 500rpm for 2h; / L sodium hydroxide to adjust the pH to 7.5, stirred at 500rpm for 2h, and then freeze-dried; put the dry powder in a closed desiccator, and reacted for 6 days at a relative humidity of 79% and a temperature of 55°C; the obtained solid was dissolved in 40mL of deionized In water, stir at 500rpm for 2h, centrifuge at 10000rpm for 15min, take the supernatant and freeze-dry, and store the dried powder in a refrigerator at 4°C to obtain corn peptide-maltodextrin glycosylation products, wherein the mass ratio of corn peptide to maltodextrin is 1:2.

[0053] Dissolve 60mg of corn peptide‐maltodextrin glycosylation product in 19.5mL of deionized water, stir at 500rpm for 1h, adjust pH5 with 0.1mol / L hydrochloric acid; dissolve 40mg of vitamin E in 10mL of absolute ethanol, stir at 500rpm for 35min; take 0.5 Add mL of v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com