High-efficient energy-saving microwave continuously-cooking and processing system for shellfish

A high-efficiency, energy-saving, processing system technology, applied in bivalve processing and other directions, can solve the problems of long processing time, low production efficiency, and a lot of labor, and achieve the effects of short heating time, quick effect, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

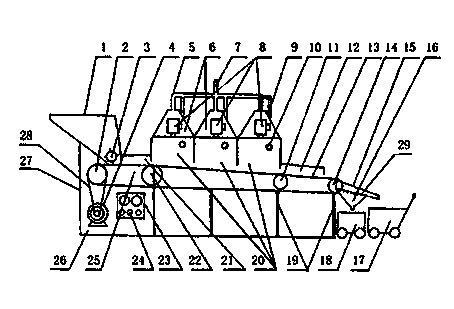

[0009] As shown in the accompanying drawings, the high-efficiency and energy-saving microwave shellfish belt-type continuous ripening processing system includes a feed hopper 1, a reduction drive main wheel shaft 2, a uniform discharge device 3, a low-speed motor 4, a heat dissipation pipe 5, a microwave bin 6, and a suction Pipe 7, microwave magnetron generator 8, exhaust pipe 9, exhaust port 10, supporting auxiliary wheel shaft 11, discharge attenuation bin 12, conveyor belt 13, driving auxiliary wheel shaft 14, diversion groove 15, juice collection funnel 16, Collection car 17, collection tank 18, outrigger 19, heating chamber 20, feeding attenuation bin 21, supporting auxiliary wheel shaft 22, switchboard 23, timing switch 24, platform 25, electric control bin 26, body 27, transmission belt 28, diversion Hole 29 is formed; body 27 is provided with platform 25, electric control bin 26, feed funnel 1, microwave bin 6 and heating chamber 20; The conveyor belt 13 is connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com