Oil-in-water-type emulsion skin cosmetic

一种水包油型、化妆品的技术,应用在化妆品、化妆品配制品、梳妆用配制品等方向,能够解决得不到皱纹等问题,达到效果优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] Hereinafter, specific examples will be given to further describe the invention of the present application. The invention of the present application is not limited thereto. In addition, the compounding quantity in an Example is mass %.

[0122] Oil-in-water emulsified skin cosmetics (creams) of the formulations shown in "Table 1" or "Table 2" were prepared by a conventional method, and the following evaluation tests were conducted by 10 female judges.

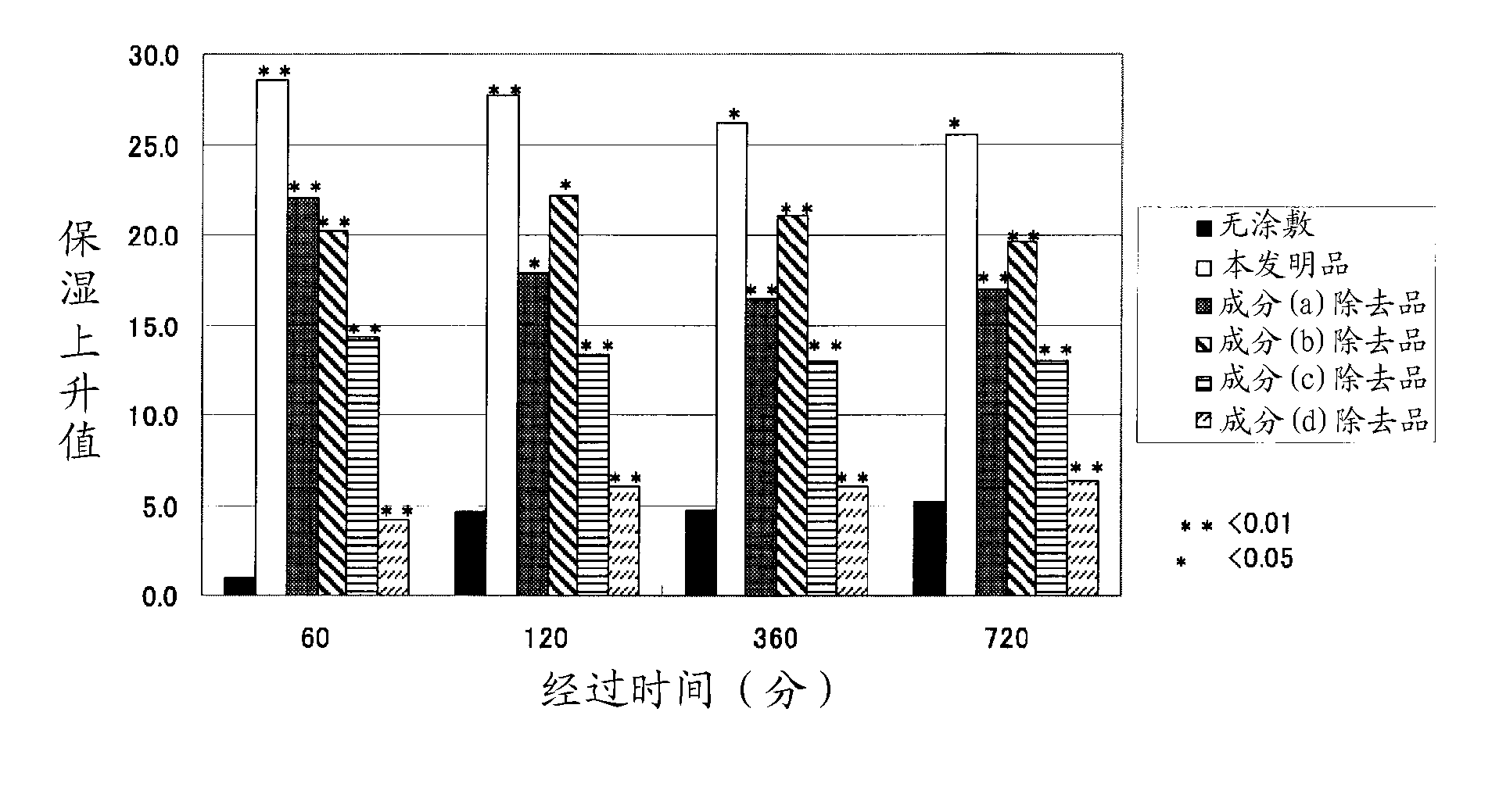

[0123] "Long-term moisturizing effect analyzed by instrument"

[0124] For the product samples (creams) of the oil-in-water emulsified skin cosmetics shown in "Table 1", the moisturizing effect was measured by instrumental analysis.

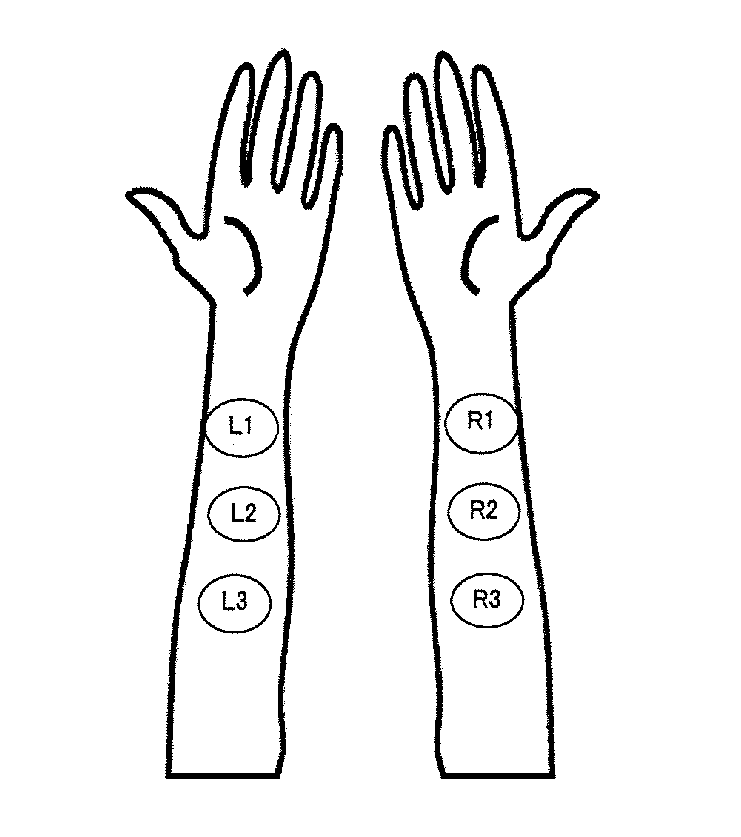

[0125] In the measurement of the moisturizing effect, a moisture meter Corneometer CM825 manufactured by Integral Co., Ltd. was used to measure figure 1 The indicated inner part of the forearm is used as the measurement site, and it is 9 cm per sample. 2 9 μl of the coated portion was ap...

Embodiment 5

[0196] [Example 5] Whitening & moisturizing cream (O / W type)

[0197] Composition Combination amount (mass%)

[0198] (1) stearyl alcohol 2.0

[0199] (2) Behenyl alcohol 1.0

[0200] (3) Hydrogenated polyisobutylene 6.0

[0201] (4) Dimethylpolysiloxane (1.5mPa?s) 7.0

[0202] (5) squalane 7.0

[0203] (6) Tripropylene glycol dipivalate 2.0

[0204] (7) 1,3-butanediol 5.0

[0205] (8) Component (D) Glycerin 10.0

[0206] (9) Dipropylene glycol 3.0

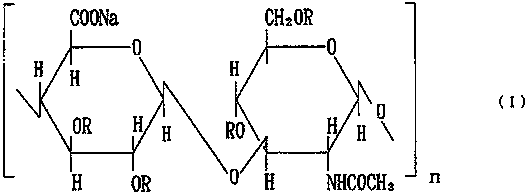

[0207] (10) Ingredient (A) Acetylated hyaluronic acid 0.005

[0208] Intrinsic viscosity: 200cm 3 / g, number of acetyl substitutions: 2.6

[0209] (11) Component (C) Dimethicone Crosspolymer / Dimethicone Blend

[0210] 25.0

[0211] (Cross-linked siloxane component: 3.0%)

[0212] Product name: 9045 Silicone Elastomer Blend [non-emulsifying cross-linked type

[0213] Silicone content 12%], manufactured by Toray Dow Corning Co., Ltd.

[0214] (12) Component (B) Polymethacryloyloxyethyl phosphorylcholine derivative

...

Embodiment 6

[0235] [Example 6] Emulsion

[0236] Composition Combination amount (mass%)

[0237] (1) Dimethylpolysiloxane (5mPa?s) 10.0

[0238] (2) Ingredient (C) Polysiloxane-11 / Decamethylcyclopentadiene

[0239] Siloxane mixture [content of component (C) 0.6%] 10.0

[0240] Product name: GRANCIL GCM-5 [non-emulsifying cross-linked silicone content 6%],

[0241] GRANT system

[0242] (3) Squalane 5.0

[0243] (4) Olefin oligomers 6.0

[0244] (5) Isotridecyl isononanoate 5.0

[0245] (6) Stearic acid PEG-20 0.3

[0246] Product name: EMALEX 820, manufactured by Japan Emaljung Co., Ltd.

[0247] (7) Sesquistearic acid sorbitan ester 0.1

[0248] Product name: NIKKOL SS-15V, manufactured by Nikko Chemikarzu Co., Ltd.

[0249] (8) Glyceryl monostearate (self-emulsifying type) 0.3

[0250] Product name: NIKKOL MGS-ASEV, manufactured by Nikko Chemikarzu Co., Ltd.

[0251] (9) Spices Appropriate amount

[0252] (10) Dipropylene glycol 1.0

[0253] (11) 1,3-butanediol 4.0

[025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com