Toothbrush

A technology for toothbrushes and handles, applied to brushes, brush bodies, household appliances, etc., can solve the problems of difficulty in covering soft resin, covering soft resin with a stable thickness, and achieve the effect of preventing defects and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

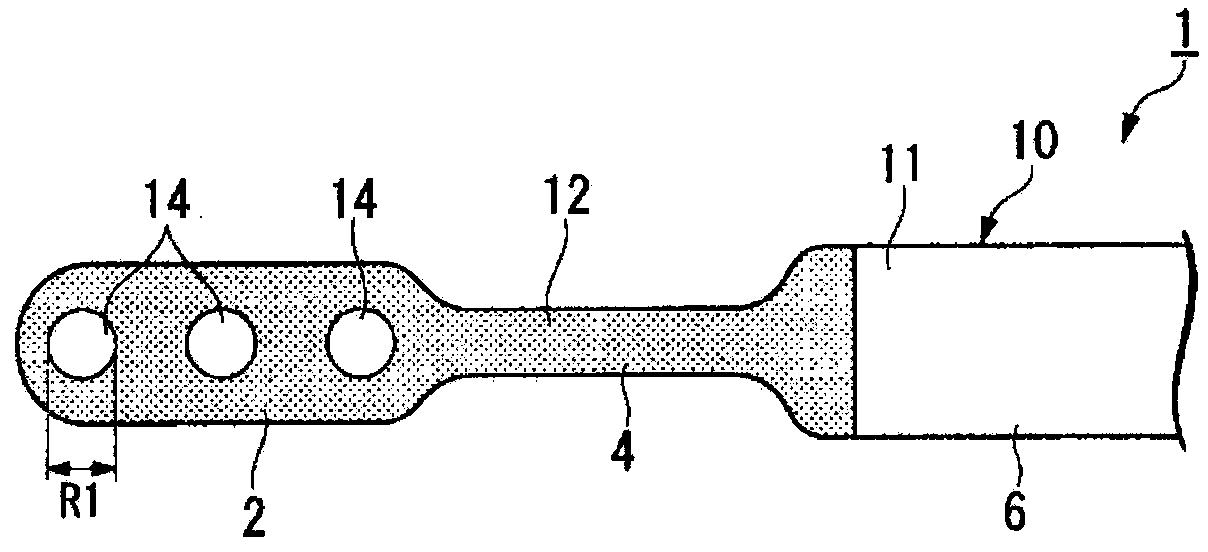

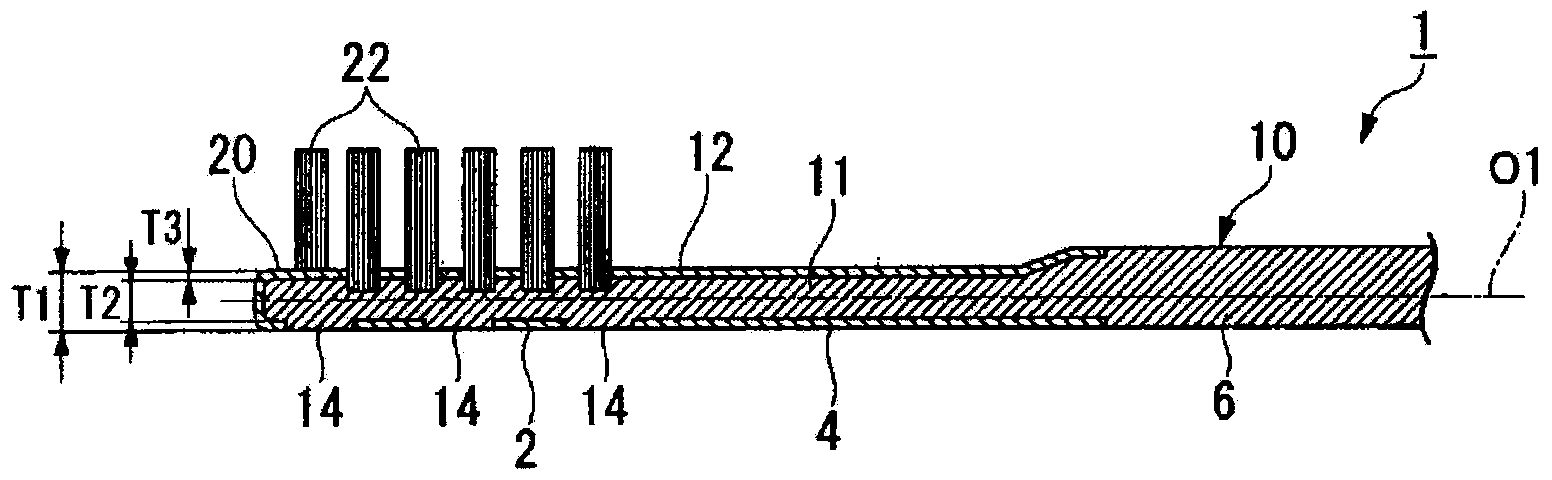

[0066] The following uses 1A~ Figure 1C The toothbrush according to the first embodiment of the present invention will be described.

[0067] Figure 1A ~ Figure 1C The toothbrush 1 shown has a handle body 10 and more than two hair bundles 22. The handle body 10 includes: a brush head 2, a neck 4 extending from the brush head 2, and a neck 4 extending from the neck 4. The handle portion 6; the hair bundle 22 is implanted on the flocking surface 20 of the brush head 2.

[0068] From the viewpoint of cleaning power, the number of bristle bundles 22 is preferably from 2 to 40, more preferably from 10 to 30.

[0069]The top view shape of the brush head 2 is a substantially rectangular shape extending from the head tip 21 to the neck 4, and its four corners are cut with curved lines. The neck portion 4 narrows from the base end of the brush head toward the handle portion 6 in a plan view, and then extends with substantially the same width, and then widens to be connected to the...

no. 2 approach

[0111] The following uses 2A~ Figure 2D The toothbrush according to the second embodiment of the present invention will be described. The same reference numerals are given to the same configurations as those of the first embodiment, and descriptions thereof will be omitted, and points different from those of the first embodiment will be mainly described. This embodiment differs from the first embodiment in the shape of the exposed portion and the position of the exposed portion.

[0112] The toothbrush 100 of this embodiment has the handle body 110 in which the coating layer 112 was formed in the surface of the base 111. As shown in FIG. On the bottom surface of the brush head 2, a substantially semicircular exposed portion 114 is formed near the top end 21 of the brush head, and a substantially quadrangular exposed portion 116 is formed near the base end of the brush head. In addition, a substantially rectangular exposed portion 118 extending in the axis O1 direction is fo...

no. 3 approach

[0120] The following uses 3A~ Figure 3D The toothbrush according to the third embodiment of the present invention will be described. The same reference numerals are given to the same configurations as those of the first embodiment, and descriptions thereof will be omitted, and points different from those of the first embodiment will be mainly described. This embodiment differs from the first embodiment in the shape of the exposed portion and the position of the exposed portion.

[0121] The toothbrush 200 of this embodiment has the handle body 210 in which the coating layer 212 was formed in the surface of the base 211. On the cover layer 212 , a substantially rectangular exposed portion 214 extending in the axial direction from the brush head 2 to the neck 4 is formed on the bottom surface.

[0122] Such as Figure 3D As shown, the exposed portion 214 is substantially in the same plane as the outer surface of the covering layer 212 .

[0123] In addition, no region where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com