Device and method for high-power laser heat management based on spray evaporation

A high-power laser, spray vaporization technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of high mobility requirements, liquid cooling heat dissipation power consumption, weight does not have advantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

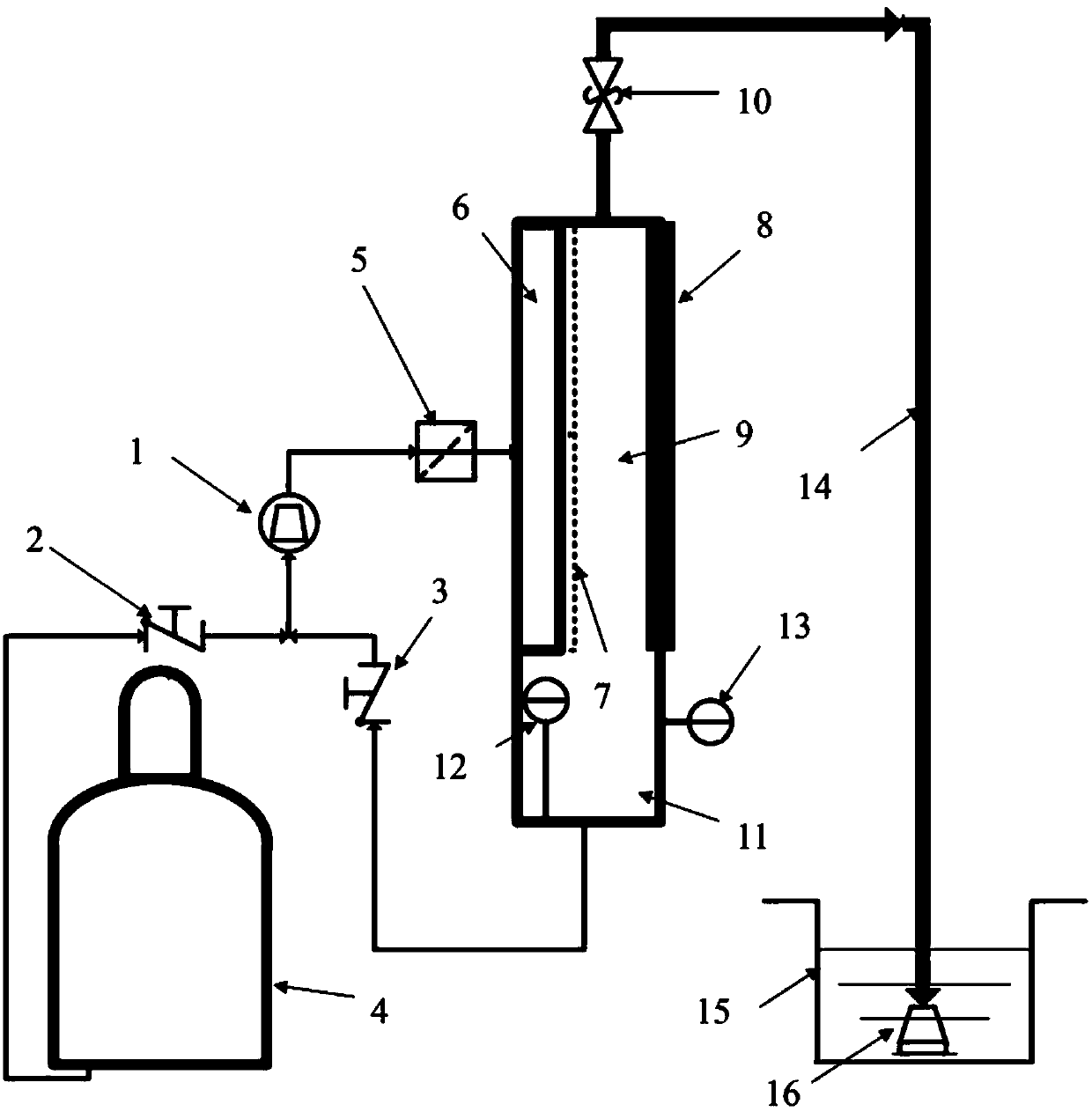

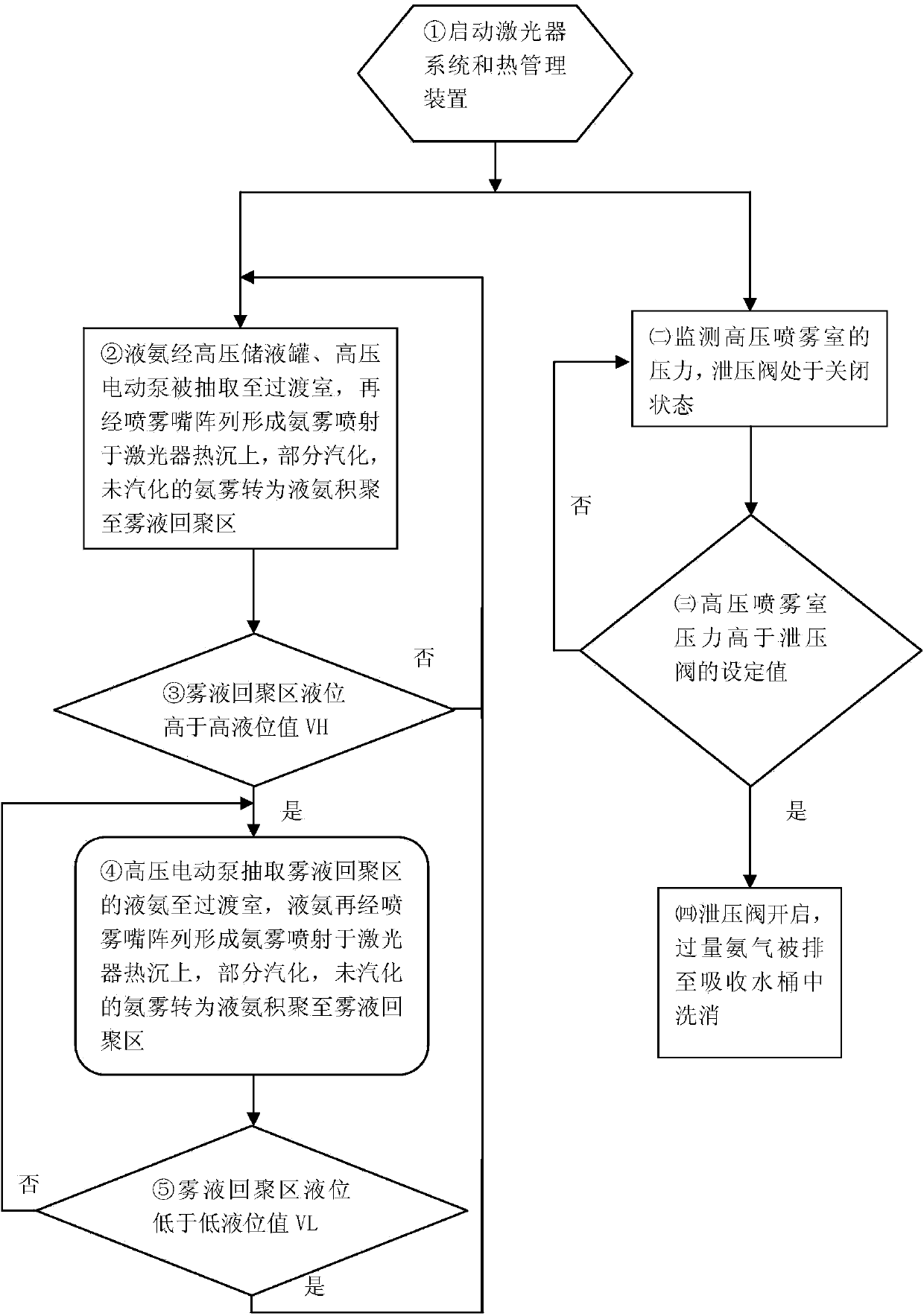

[0045] A high-power laser heat management device based on spray vaporization of the present invention, a laser heat sink 8 is provided on the high-power laser, and the microstructure of the heat dissipation surface of the laser heat sink 8 is a groove structure, which can enhance the heat exchange effect. Such as figure 1 As shown, the heat management device includes a high-pressure spray chamber 9 installed on the laser heat sink 8, and the high-pressure spray chamber 9 is provided with a refrigerant for converting liquid refrigerant into mist liquid droplets and spraying it on the laser heat sink 8. The spray nozzle array 7 and an air pressure sensor 13 on the upper surface, the mist-like liquid droplet refrigerant sprayed on the laser heat sink 8 is partially vaporized to form a gas refrigerant, which can increase the pressure in the high-pressure spray chamber 9, and the air pressure sensor 13 can measure in real time The pressure in the high-pressure spray chamber 9 is fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com