Preparation method of membrane electrode of direct methanol fuel cell

A methanol fuel cell and membrane electrode technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of disorder of the catalytic layer, restricting the performance and function of the battery, and low structural controllability, and achieve mass transfer efficiency and catalyst. Utilize the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

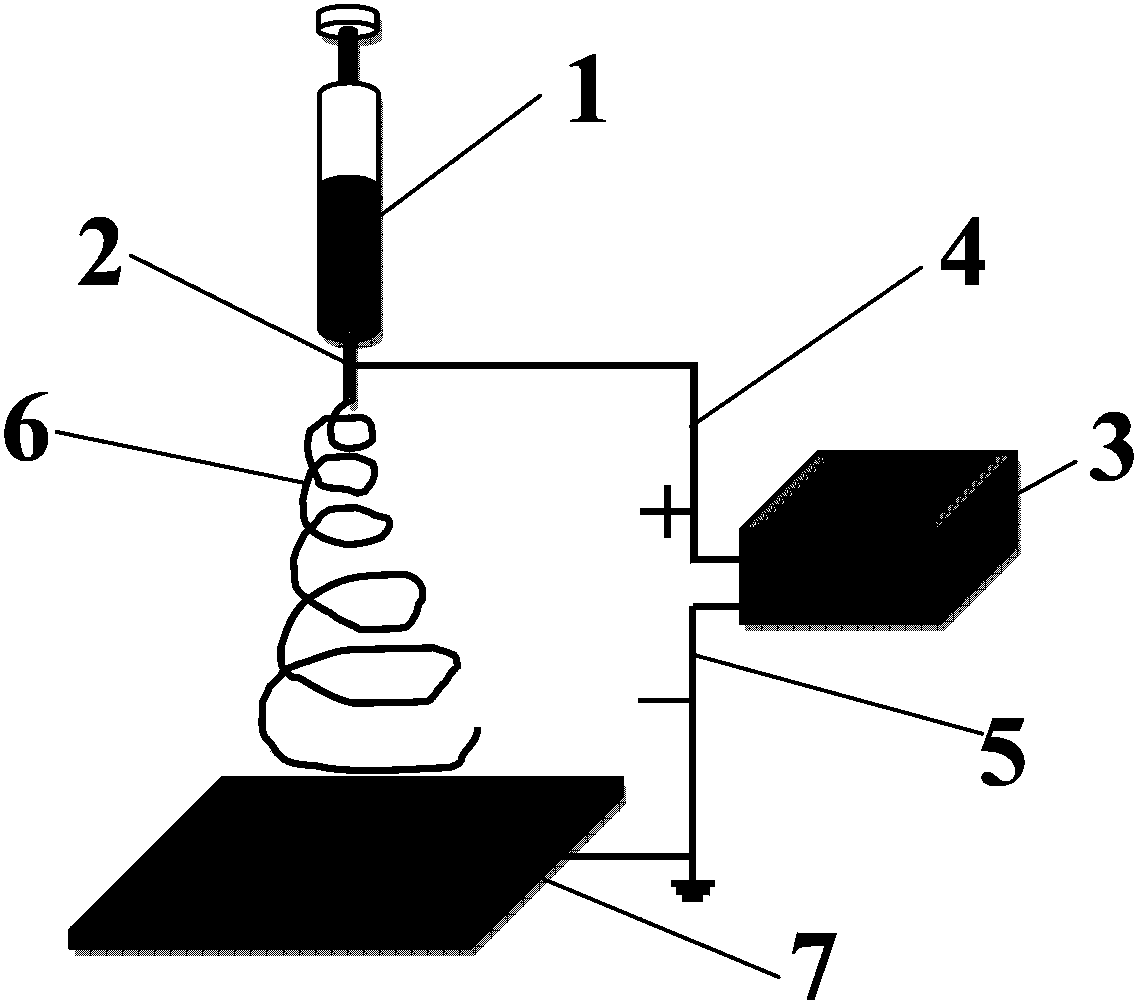

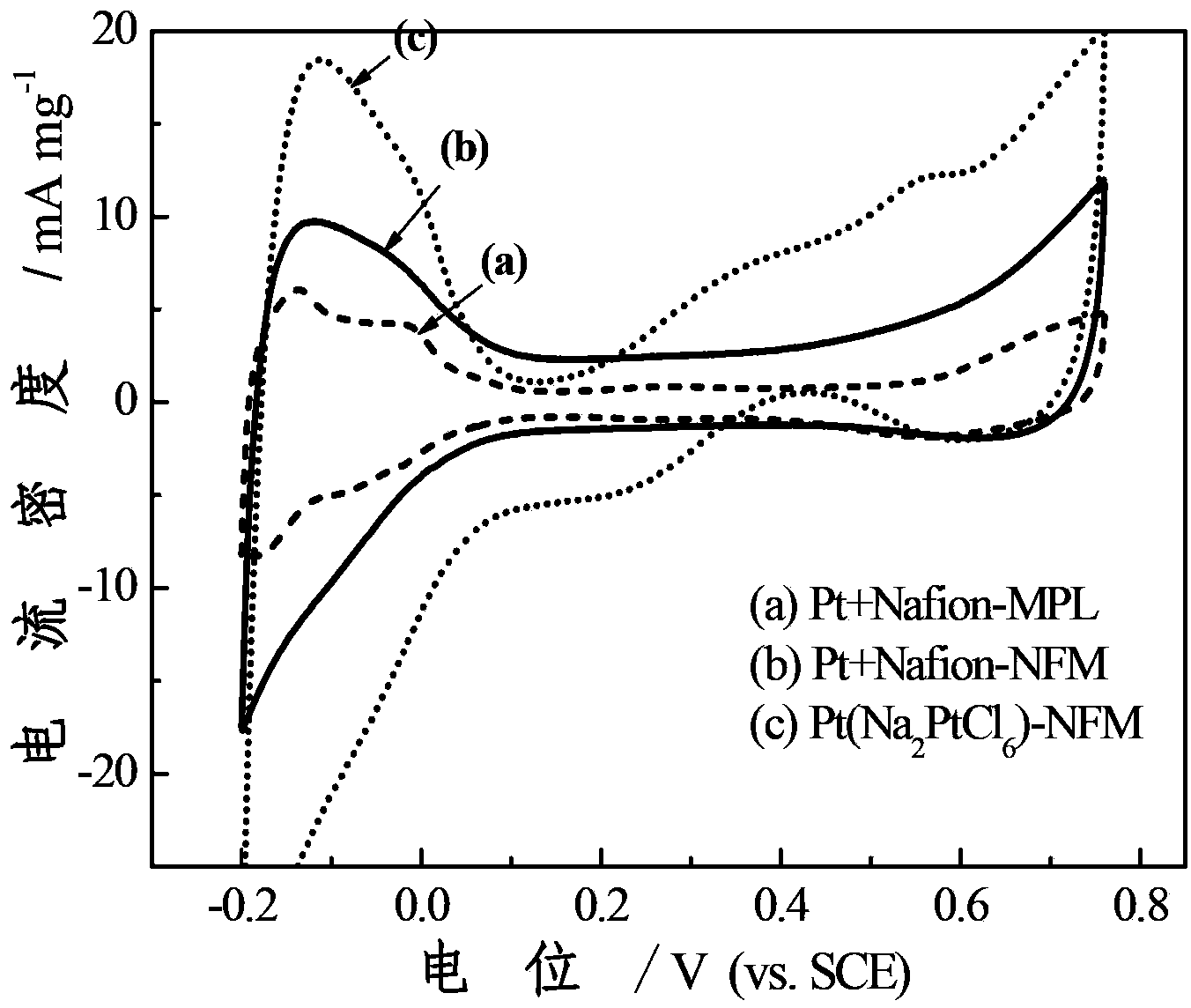

[0069] The Nafion / carbon powder mixed nanofiber network structure film was constructed by electrospinning technology, and then the commercial Pt catalyst was directly deposited on the surface to make the cathode membrane electrode of the direct methanol fuel cell.

[0070] 1. Weigh 133mg of Vulcan XC-72R activated carbon spheres and disperse them into 2g of DuPont's 5wt% Nafion resin solution (the solvent is a mixture of water and low-carbon alcohol, and the mass ratio of water to low-carbon alcohol is 58:42) In the process, after stirring for one hour, a homogeneous activated carbon slurry was obtained by ultrasonication at room temperature for 3 hours; the low-carbon alcohol could be isopropanol, butanol, ethanol or methanol.

[0071] 2. Weigh 0.8g of PVA (110kD) powder and disperse it into 9.2mL of deionized water, stir at 80°C for 24 hours to obtain a uniform 8wt% PVA solution.

[0072] 3. Weigh 834mg of 8wt% PVA solution and add it to the uniformly stirred activated carbo...

Embodiment 2

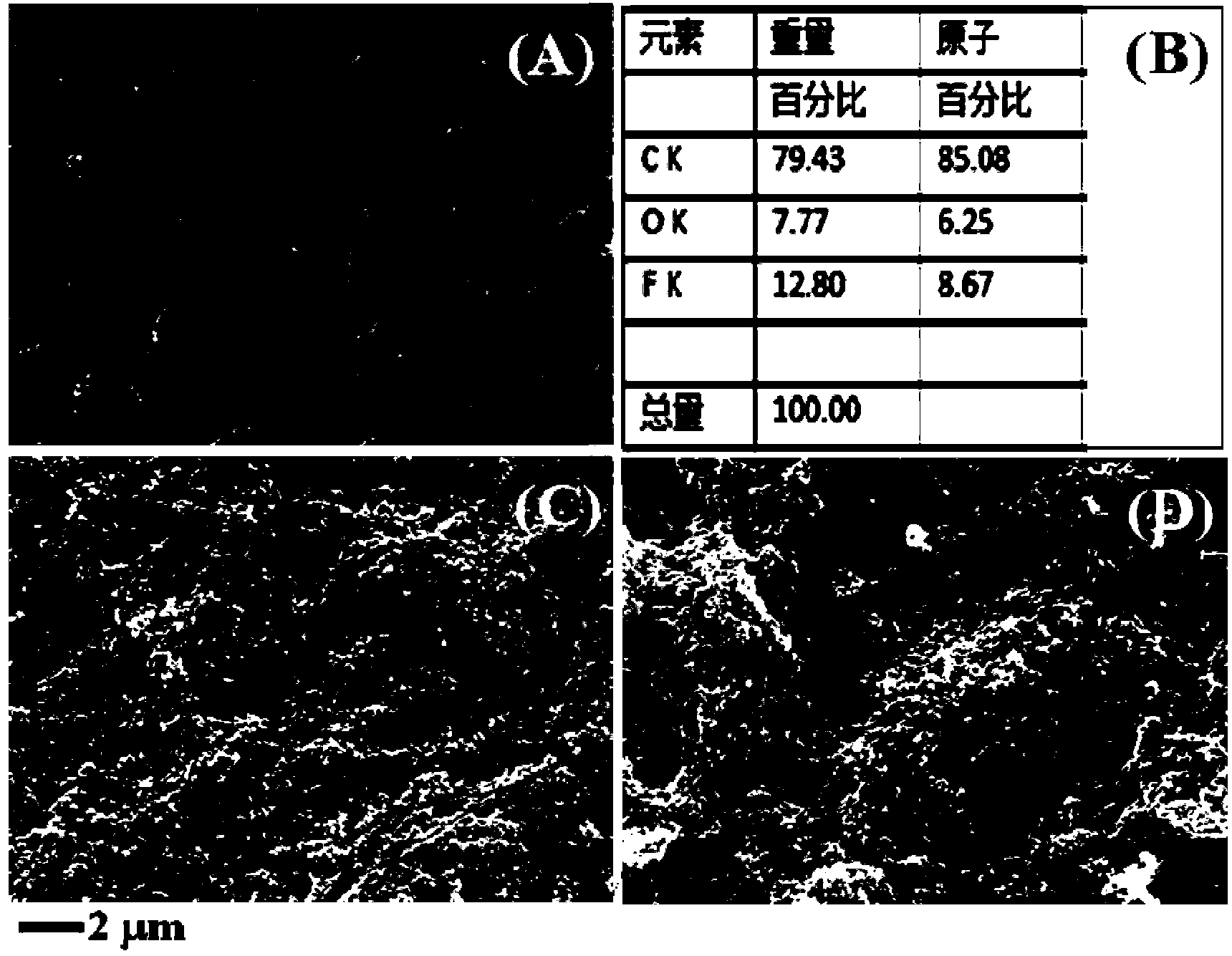

[0078] The Nafion / carbon powder mixed nanofiber network structure film was constructed by electrospinning technology, and then the surface was impregnated with Na 2 PtCl 6 Precursor + hydrogen reduction method to reduce catalyst to prepare cathode membrane electrode for direct methanol fuel cell.

[0079] 1. Prepare XC-72R / Nafion / PVA (4:3:2 by weight) nanofiber membrane according to steps 1-4 of Example 1.

[0080] 2. Weigh 28.6mg Na 2 PtCl 6 (Pt content 35wt%, Pt=10mg) powder, join 2mL isopropanol and water (volume ratio IPA:H 2 O=1:1) in the mixture, dissolved. Measure 200 μL of the above precursor solution with a micro-syringe and evenly drop it to 1×1 cm 2 The surface of the nanofibrous membrane was dried at room temperature.

[0081] 3. Transfer the nanofibrous membrane containing the precursor to a tube furnace, and pass N 2 / H 2 Mixed gas (hydrogen volume content 5%), according to 1 ℃.min -1 The heating rate was slowly raised to 120°C, kept for 2 hours, then sl...

Embodiment 3

[0086] The Nafion / carbon powder mixed nanofiber network structure film was constructed by electrospinning technology, and then the anode membrane electrode of direct methanol fuel cell was prepared by surface deposition of commercial PtRu catalyst.

[0087] 1. Prepare XC-72R / Nafion / PVA (4:3:2 by weight) nanofiber membrane according to steps 1-4 of Example 1.

[0088] 2. Weigh 10 mg of PtRu black and disperse it into 2.5 mL of deionized water, add 0.5 mL of 5wt% Nafion resin solution, sonicate at room temperature for 1 hour, add 3 mL of isopropanol, and continue to sonicate at room temperature for 1 hour to obtain a uniform catalyst slurry. Measure 300 μL of the above catalyst slurry through a micro-syringe and evenly drop it to 1×1 cm 2 On the surface of the gas diffusion layer, a PtRu+Nafion-MPL catalytic layer is formed (PtRu loading is 0.5mg.cm -2 ); also take 300 μL of the above catalyst slurry through a micro-syringe 2 On the surface of the nanofiber membrane, a PtRu+Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com