Polyurethane direct buried insulation pipe digital two-step filling operation line

A direct-buried thermal insulation pipe and polyurethane technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of not being able to place in place in time and accurately, hurting the worker's head, and breaking the wire rope, so as to reduce the number of cranes The effect of using, improving production efficiency and reducing hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

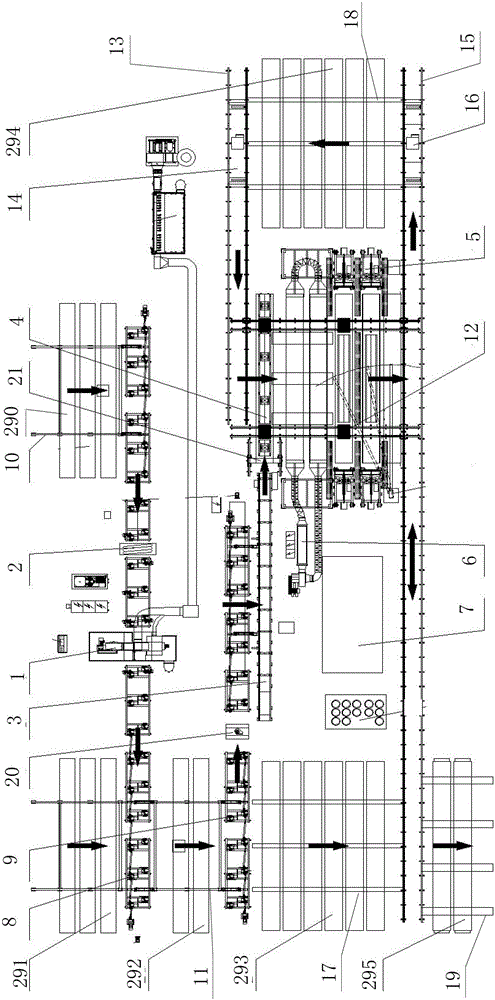

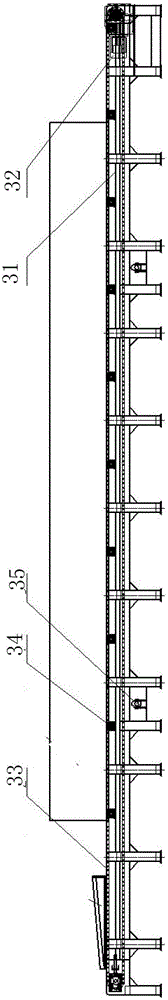

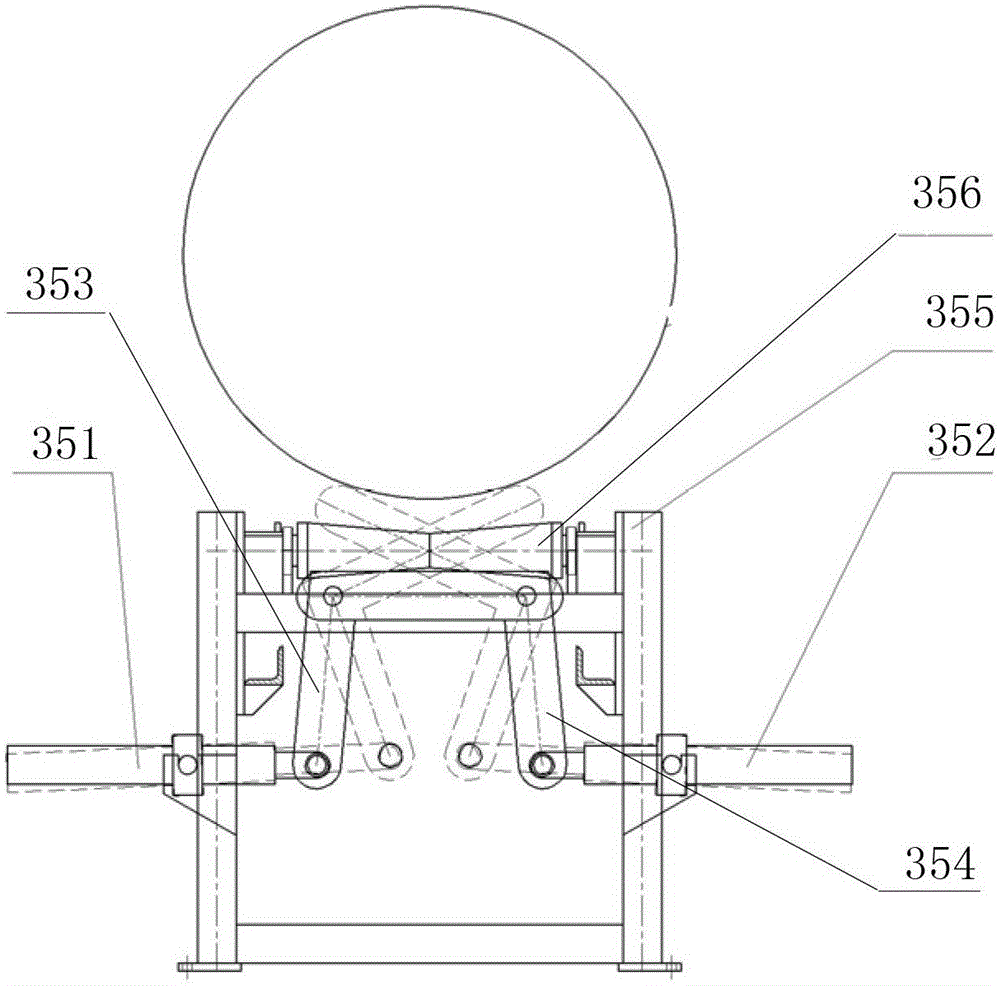

[0032] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a digital two-step filling operation line for polyurethane directly buried insulation pipes, including a steel pipe transmission unit, a rust and dust removal system 1, an intermediate frequency heating device 2, a pipe threading machine 3, a lifting and moving V-shaped box 4, and a blocking machine 5. The preheating device 6 before foaming and the polyurethane foaming unit 7; the steel pipe transmission unit is composed of a steel pipe transmission unit 8 for the derusting line and a steel pipe transmission unit 9 before passing through the pipe, the rust removal and dust removal system 1 and the intermediate frequency heating device 2 Installed in the middle position of the steel pipe transmission unit 8 of the derusting line, one end of the steel pipe transmission unit 8 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com