Drive shaft capable of preventing overload fracture

A transmission shaft and joint technology, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of large output torque of the transmission shaft, casualties, damage to the main equipment, etc., to improve productivity and safety. The effect of sex and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

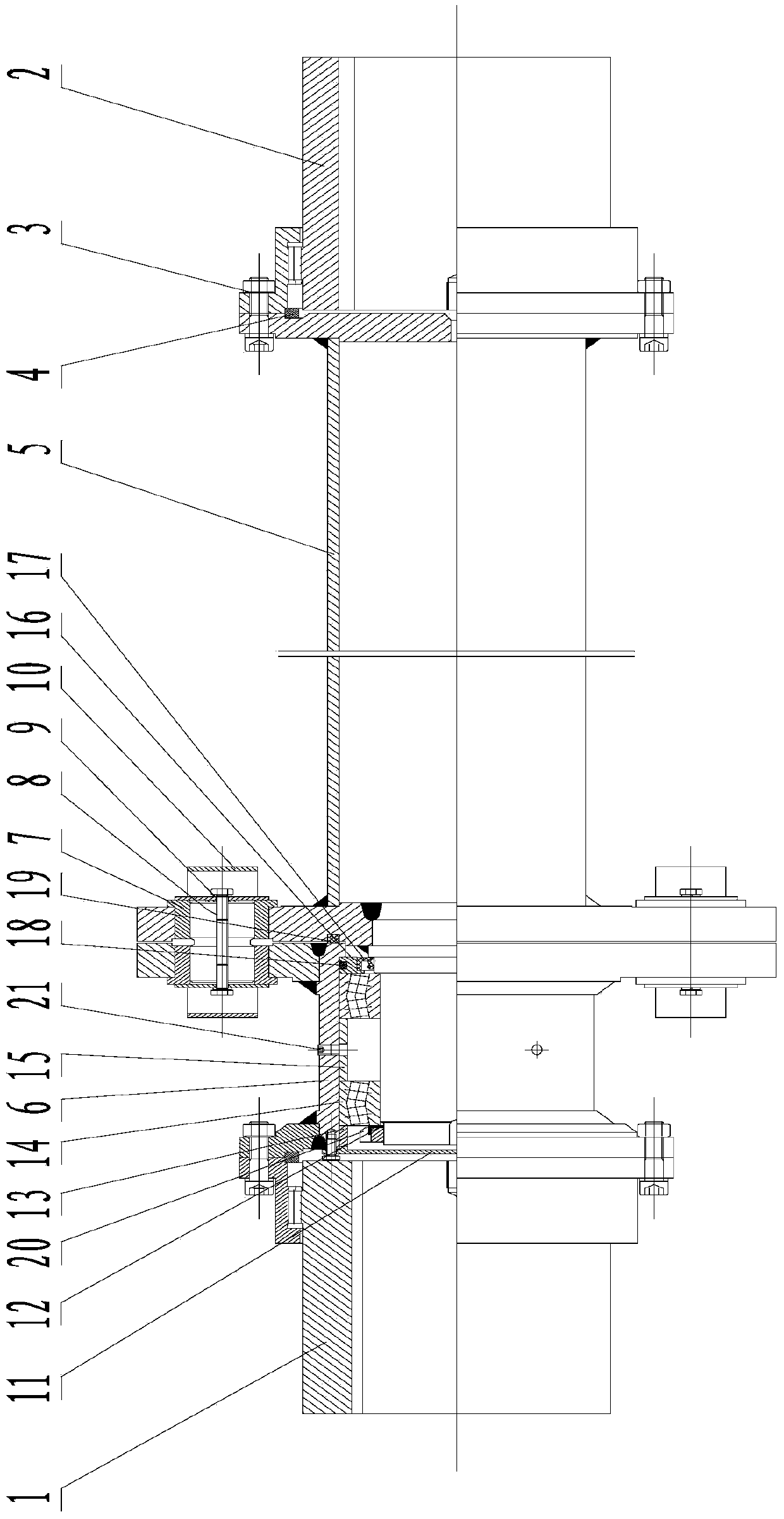

[0020] Such as figure 1 As shown, a transmission shaft for preventing overload fracture, comprising: half coupling one 1, half coupling two 2, connecting body one 5, connecting body two 6, sleeve 7 and safety pin 8; said half coupling The left end of device one 1 is connected with the input shaft of the gearbox with a key, and the right end of half coupling two 2 is connected with the output shaft of the main motor with a key, through the half coupling one 1 and Coupling half 2 realizes the transmission of torque from the main motor to the gearbox, and then drives the equipment to work; the right side of coupling half 1 is fixedly connected with connecting body 2 6 by bolts, so that the torque of connecting body 2 6 Can be transmitted to half coupling one 1, the left end of the connecting body one 5 is welded with a shaft head, and the shaft head of the connecting body one 5 can be inserted into the inner cavity of the right end of the connecting body two 6 to be axially fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com