Permeation boosting heat-power conversion circulating device

A circulation device and thermal power conversion technology, which is applied in steam engine devices, energy-saving heating/cooling, lighting and heating equipment, etc., can solve the problems of high technical difficulty, low efficiency, easy cavitation and unit power cost, etc., so as to avoid technical difficulty big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

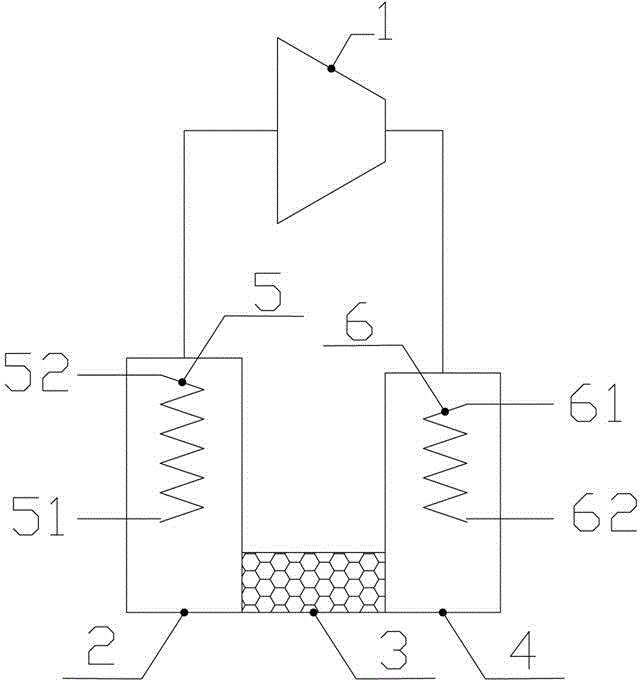

[0034] see figure 1 The working medium outlet of the expander 1 is connected to the working medium inlet of the condenser 2 through a pipeline, the working medium outlet of the condenser 2 is connected to one surface of the semi-permeable membrane module 3, and the other surface of the semi-permeable membrane module 3 is connected to the generator 4 The working medium inlet and the working medium outlet of the generator 4 are connected to the inlet of the expander 1 through pipes, the condenser 2 has a built-in cooling coil 5, and the generator 4 has a built-in heating coil 6;

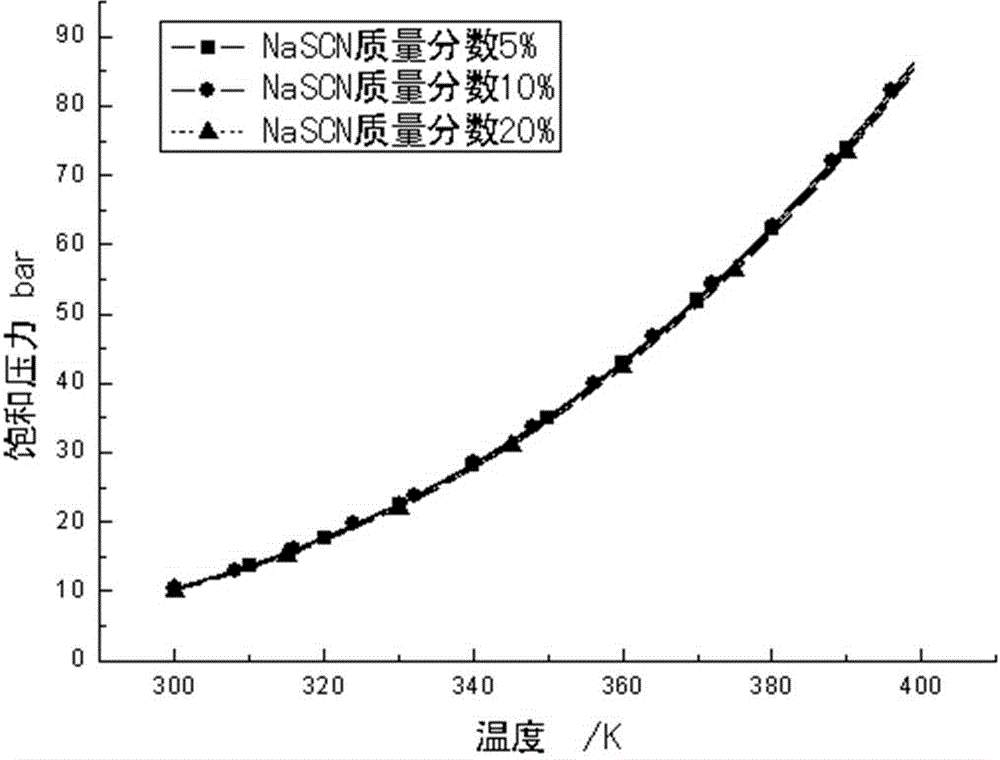

[0035] The circulating working fluid is ammonia (NH 3 ), the solution is ammonia-sodium bisulfate (NH 3 -NaSCN) solution, the solvent of the solution is ammonia (NH 3 ), the solutes are sodium bisulfate (NaSCN), ammonia (NH 3 ) is the circulating working fluid. The thermal fluid is heat transfer oil;

[0036] The temperature of the thermal fluid inlet 61 is 120°C and the temperature of the thermal...

Embodiment 2

[0044] The structure of the device is the same as in Embodiment 1.

[0045] The circulating working fluid is ammonia (NH 3 ), the solution is ammonia-sodium bisulfate (NH 3 -NaSCN) solution, the solvent of the solution is ammonia (NH 3 ), the solutes are sodium bisulfate (NaSCN), ammonia (NH 3 ) is the circulating working fluid. The thermal fluid is heat transfer oil;

[0046] The temperature of the thermal fluid inlet 61 is 140°C and the temperature of the thermal fluid outlet 62 is 120°C;

[0047] The temperature of the cooling water inlet 51 is 20°C, and the temperature of the cooling water outlet 52 is 30°C;

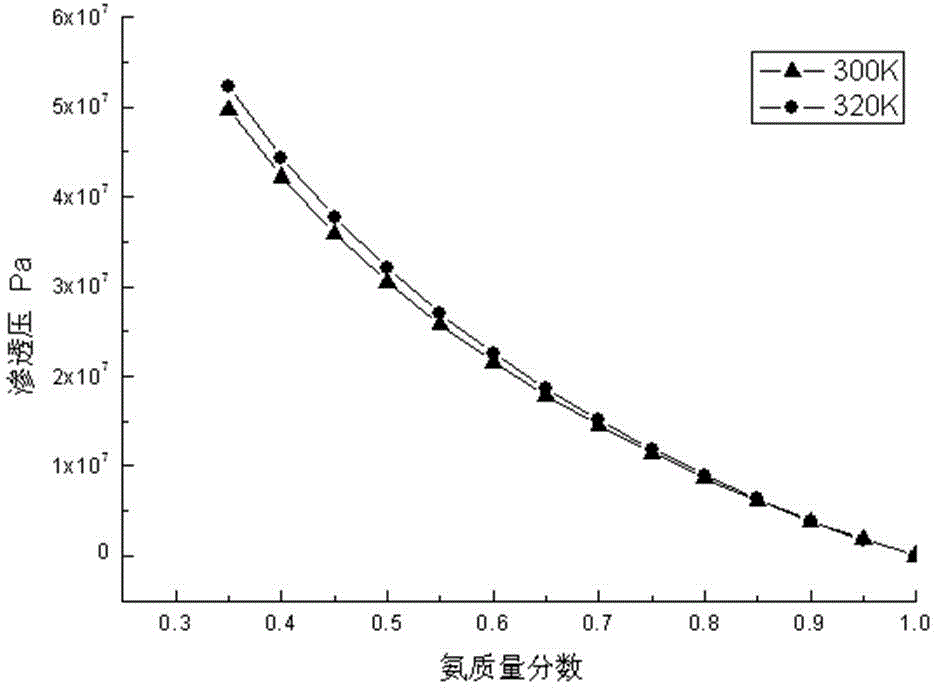

[0048] Generator 4 surface solution temperature is 120°C, NH 3 The mass fraction of is 50% (corresponding to 50% solute concentration);

[0049] At the junction of generator 4 and semi-permeable membrane module 3, the solution temperature is 27°C, NH 3 The mass fraction of is 60% (corresponding to 40% solute concentration). According to literature [5], at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com