Fe-Ni alloy/C composite nanofiber microwave absorbent, preparation method and application of absorbent

A technology of composite nanofibers and microwave absorbers, applied in the direction of fiber chemical characteristics, radiation-absorbing coatings, chemical instruments and methods, etc., can solve the problems of poor anti-oxidation and corrosion resistance, limit normal use, etc., and achieve improved microwave absorption The effect of performance, light weight and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The method for preparing the Fe-Ni alloy / C composite nanofiber microwave absorber provided by the invention mainly includes the preparation of the solution, the electrospinning process of the precursor fiber and its preoxidation and carbonization treatment. The specific steps are:

[0021] (1) Add a certain amount of polyacrylonitrile (PAN, average molecular weight 150,000) into an appropriate amount of solvent dimethylformamide (DMF), heat in a water bath at 50-70°C and magnetically stir for 2-5 hours until PAN is completely dissolved, Then add a certain amount of iron acetylacetonate and nickel acetylacetonate, and continue magnetic stirring at room temperature for 10-15 hours to obtain a uniform, transparent and stable spinning solution. The mass fraction of PAN in the spinning solution is 5-12% (preferably 6-10%), the mass fraction of iron acetylacetonate and nickel acetylacetonate is 4-13% (preferably 6-10%), and the rest is solvent DMF.

[0022] (2) Move the prep...

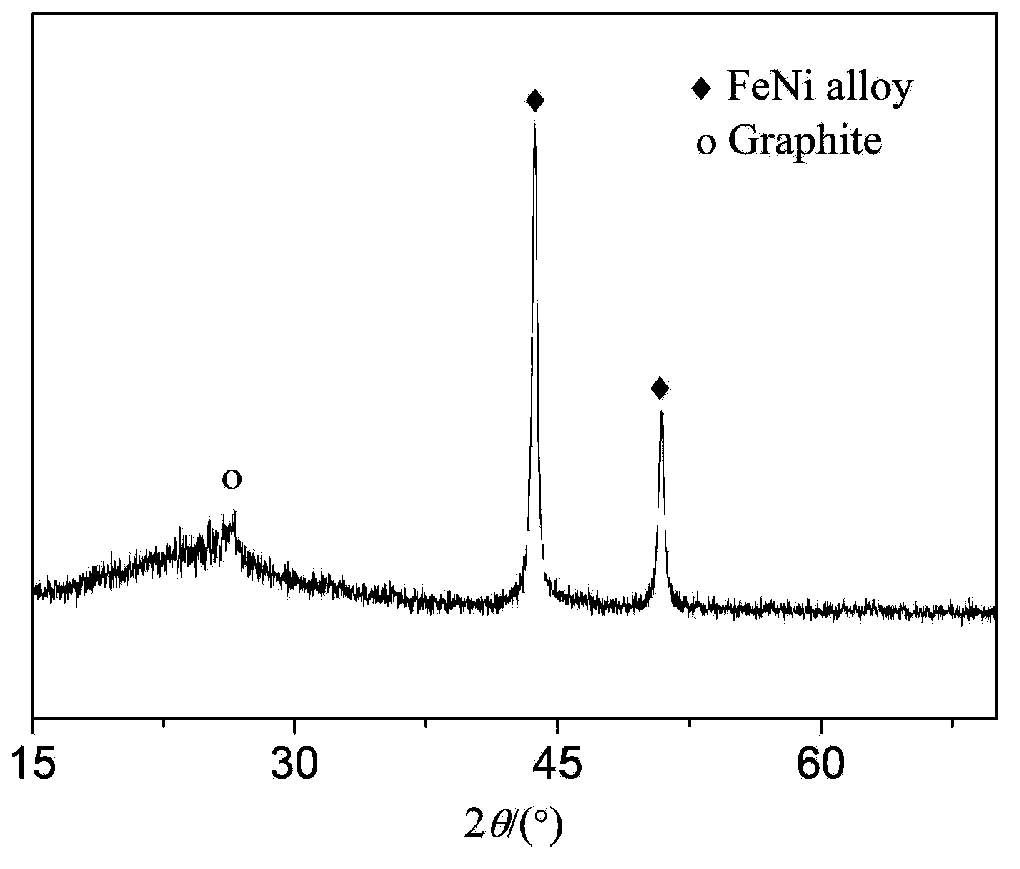

Embodiment 1

[0026] Add 0.7g of PAN into a conical flask containing 8.6g of DMF, heat in a water bath at 50°C and stir magnetically for 3h until PAN is completely dissolved, then add 0.5133g of iron acetylacetonate and 0.1867g of nickel acetylacetonate, and continue the magnetic Stir for 15 hours to obtain a uniform, transparent and stable spinning solution. The mass fraction of PAN in the spinning solution is 7%, the mass fraction of the metal salt is 7%, and the rest is the solvent DMF. The prepared spinning solution was moved into the electrospinning device, and the voltage was 12kV, the receiving distance was 23cm, the solution supply rate was 0.3mL / h, the spinneret diameter was 0.8mm, the ambient temperature was 20-25°C, and the humidity was Under the condition of 35-45%, electrospinning is carried out to make PAN / acetylacetonate iron-nickel composite precursor fiber, and the collected precursor fiber is put into an oven and dried at 80°C for 10h. The dried precursor fibers were pre-...

Embodiment 2

[0028] Basic process is the same as embodiment 1. The difference is: the carbonization temperature is 1000°C, and the average diameter of the obtained Fe-Ni alloy / C composite nanofiber is about 280nm; when the coating thickness is 1.9mm, the minimum reflection loss reaches –41dB, and the effective absorption bandwidth is 9.2 GHz, the frequency range is 8.8-18GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com