Method for producing naphthenic base refrigerating machine oil base oil by using coal tar oil

A technology for refrigerating machine oil and coal tar, which is applied in the petroleum industry, processing hydrocarbon oil, hydrogenation process, etc. It can solve the problems of long process, unprepared refrigerating machine oil, and high quality, and achieve high quality and extend the hydrogenation industry chain , The effect of broadening the source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

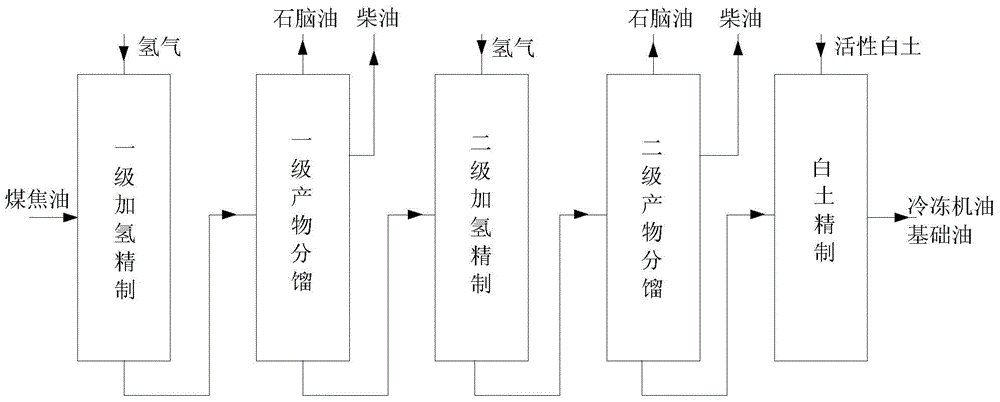

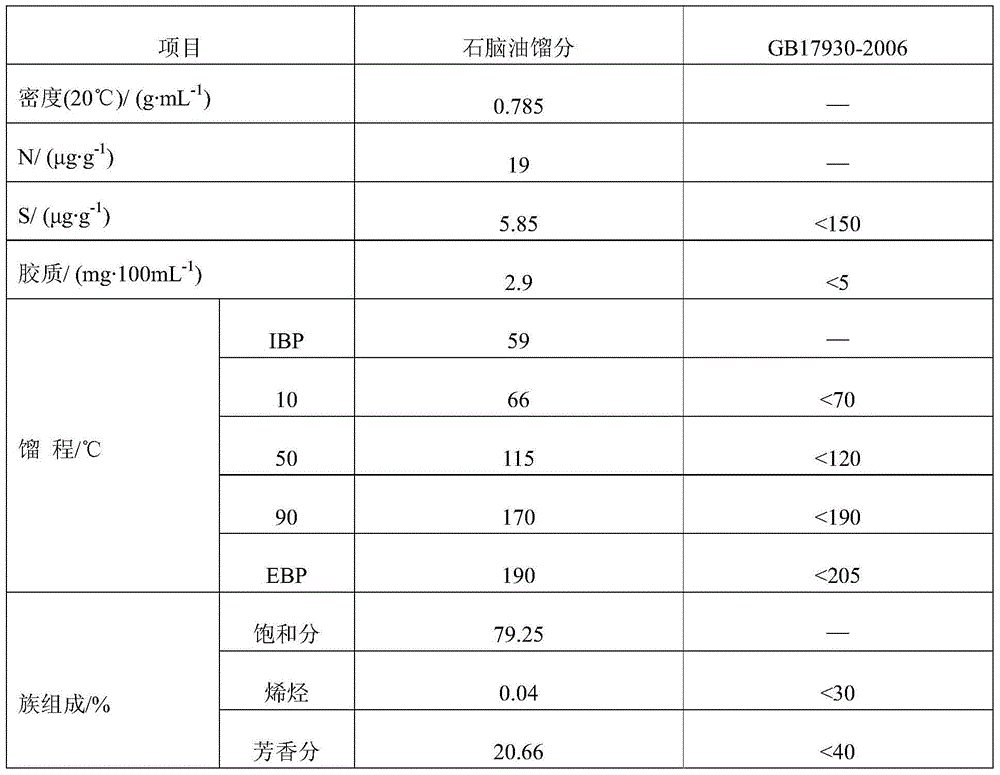

[0036] In this embodiment, the medium and low temperature coal tar produced in the coal pyrolysis process is used as raw material to prepare naphthenic refrigerating machine oil base oil, and the method is realized by the following steps:

[0037] (1) Primary hydrotreating of coal tar

[0038]Mix medium and low temperature coal tar and hydrogen into the primary hydrogenation reactor for primary hydrogenation refining. The reaction temperature is 370°C, the reaction pressure is 14MPa, the hydrogen-oil volume ratio is 1000:1, and the liquid volume space velocity is 0.3h -1 , to obtain a first-grade coal tar hydrorefining product;

[0039] The primary hydrotreating catalyst used in this example is the TK-561 catalyst developed by TOPSOE (http: / / www.topsoe.com / products / CatalystPortfolio.aspx), which uses aluminum oxide as a carrier and has a catalytic activity of The content of molybdenum trioxide in the metal is at least 20wt%, the content of nickel oxide is at least 5wt%, the t...

Embodiment 2

[0059] In this example, the reaction temperature of step (1) is 380°C, the reaction pressure is 15MPa, the volume ratio of hydrogen to oil is 800:1, and the liquid volume space velocity is 0.4h -1 , to obtain the primary coal tar hydrorefining product; in step (3), the residual oil fraction is mixed with hydrogen and then carried out in the secondary hydrogenation reactor for secondary hydrorefining, the reaction temperature is 360 ° C, and the reaction pressure is 15 MPa , the volume ratio of hydrogen to oil is 800:1, and the liquid volume space velocity is 0.8h -1 . The other steps were the same as in Example 1 to obtain refrigerating machine oil base oil, the yield of which is shown in Table 4, and the properties of the obtained refrigerating machine oil base oil were shown in Table 5.

Embodiment 3

[0061] In this example, the reaction temperature of step (1) is 370°C, the reaction pressure is 14MPa, the volume ratio of hydrogen to oil is 1000:1, and the liquid volume space velocity is 0.3h -1 , the primary hydrotreating catalyst used is the FZC-41A catalyst produced by Shandong Gongquan Chemical Co., Ltd. (http: / / www.gqcat.com.cn / Chinese / ProductList.asp?PID=25), and the primary Coal tar hydrorefining product; in step (3), after mixing the residual oil fraction with hydrogen, carry out secondary hydrofining in the secondary hydrogenation reactor, the reaction temperature is 360°C, the reaction pressure is 13MPa, and the volume of hydrogen oil The ratio is 800:1, and the liquid volume space velocity is 0.7h -1 , the secondary hydrorefining catalyst used is the FV-1 catalyst of China Petrochemical Corporation (http: / / www.sinopec.com / products_services / for_business / catalysts / ). The other steps were the same as in Example 1 to obtain refrigerating machine oil base oil, the yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com