System for recycling raw gas afterheat of coke oven

A waste heat recovery and waste gas technology, which is applied in the heating of coke ovens, coke ovens, steam generation methods using heat carriers, etc., can solve the problem of high temperature treatment, unsatisfactory use of heat exchangers, large external environmental impacts, and reduce accidents In order to ensure safe and normal operation, reduce the incidence of accidents, and promote the circulation of heat exchange medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

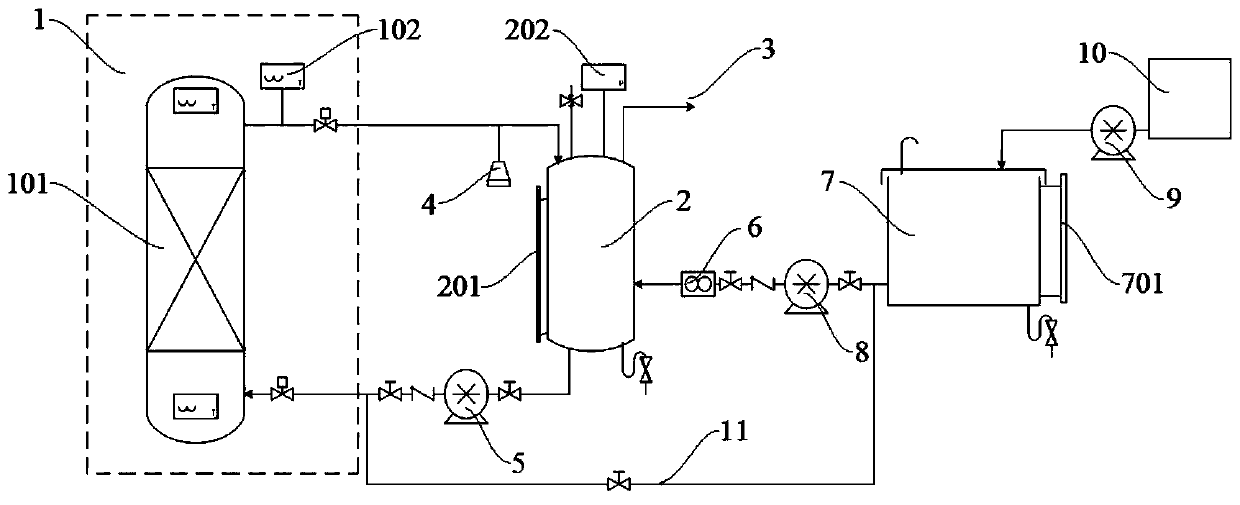

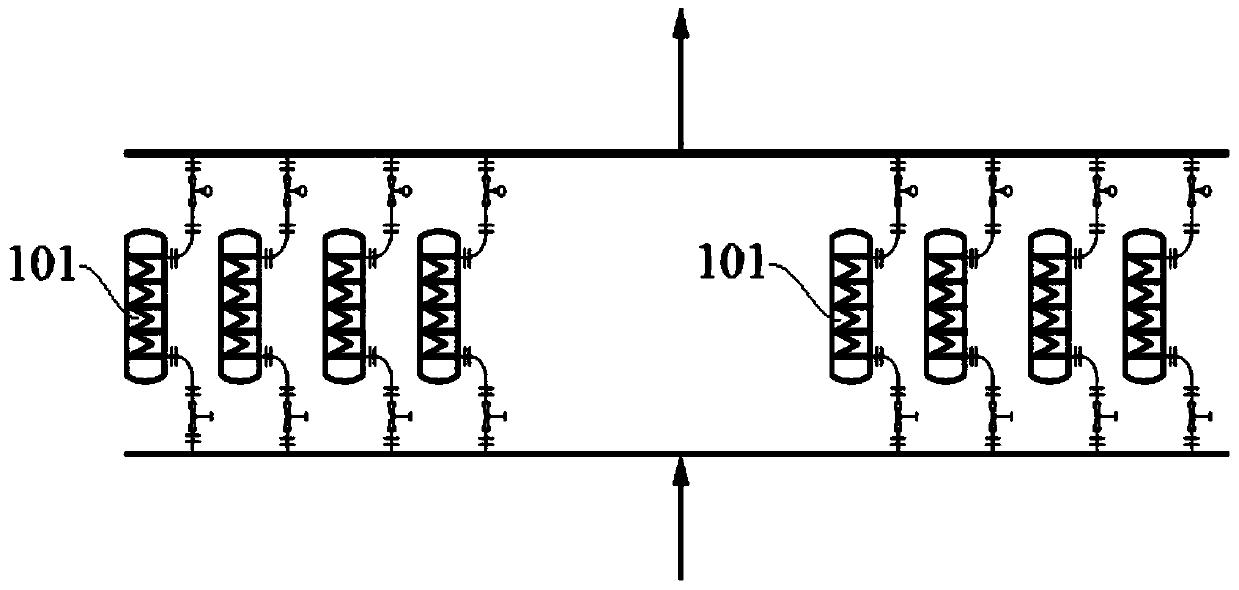

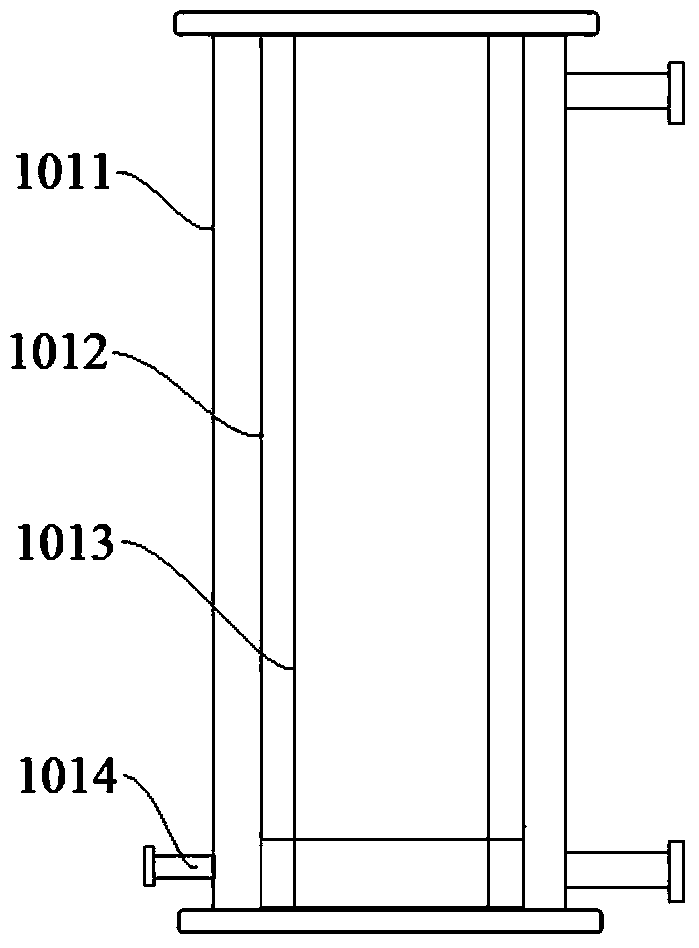

[0036] Combine figure 1 , figure 2 with image 3 , The waste heat recovery and utilization system of coke oven raw gas of this embodiment includes a heat exchange medium circulation system, a water supplement system and a detection control system, wherein:

[0037] The heat exchange medium circulation system includes heat exchanger group 1, steam drum 2 and forced circulation pump 5. The water inlet of heat exchanger group 1 is connected to the water outlet of steam drum 2 through forced circulation pump 5. The water outlet is connected with the water inlet of the steam drum 2, and the steam outlet 3 on the steam drum 2 is connected with the external steam pipe network, which can forcibly promote the circulation of the heat exchange medium to ensure uninterrupted steam generation, and the recovery rate can reach 30%. The recovered steam is merged into the existing coking steam pipe network and used, which reduces the energy consumption of the coking process and ensures the long-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com