Method for preparing polyetherketone foaming material by using supercritical CO2

A foaming material, polyether ketone technology, applied in the field of materials, to achieve the effect of high cell density, simple foaming process, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

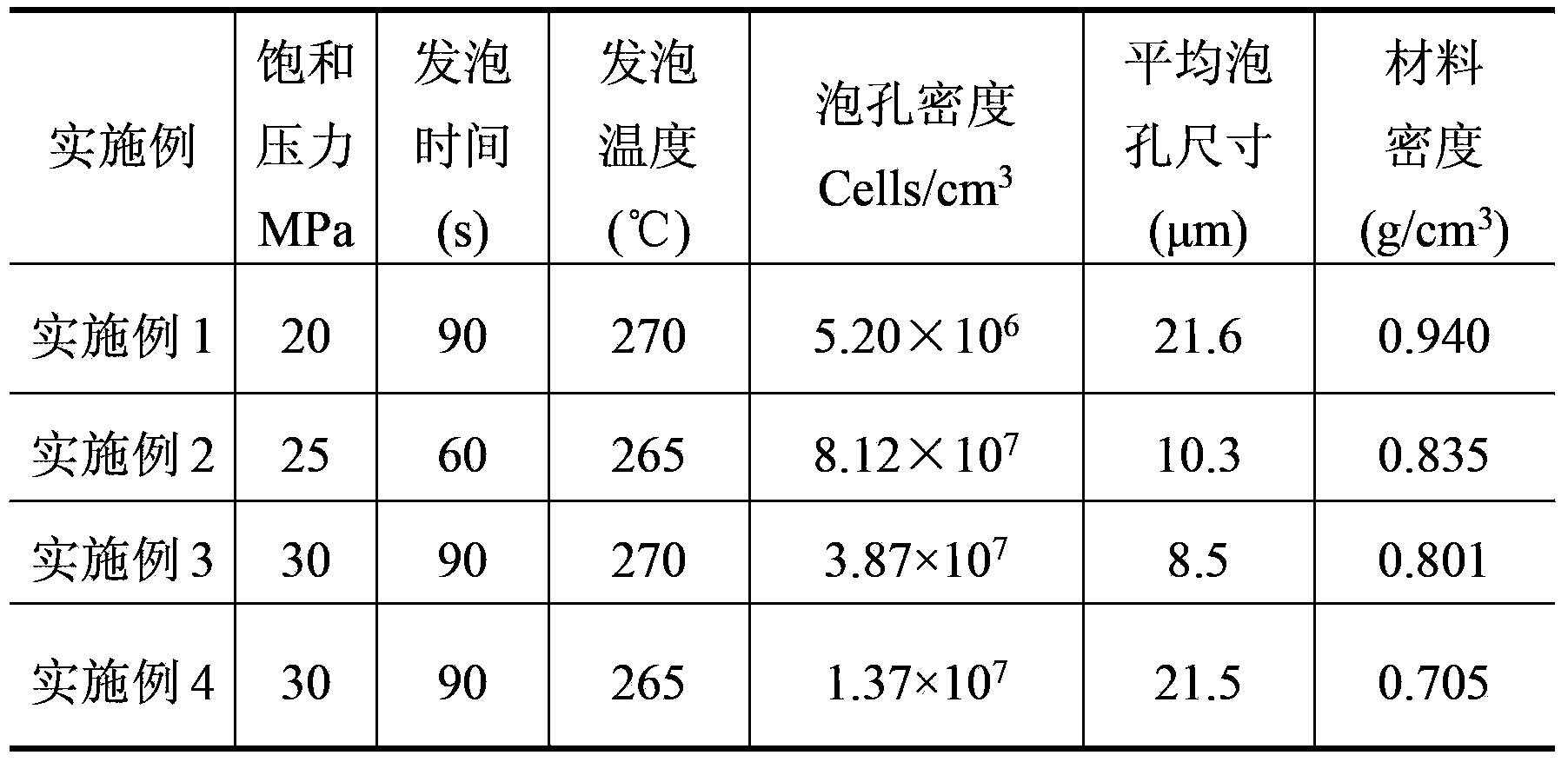

Embodiment 1

[0023] (1) Add 14g of PPEK fine powder evenly into the mold, put it into a muffle furnace to melt and plasticize for 60 minutes, and then mold a 3mm PPEK sheet on a flat vulcanizing machine;

[0024] (2) Place the sheet obtained in step (1) in an autoclave, and pass through supercritical CO 2 Perform saturation, the saturation pressure is 20MPa, the saturation temperature is 50°C, and a saturated PPEK sheet is obtained after 60 minutes;

[0025] (3) Put the sheet obtained in step (2) into an oil bath at a temperature of 270°C and foam for 90 seconds to obtain a PPEK foam sheet.

[0026] The density of the PPEK foam sheet prepared above is 0.940g / cm 3 ,

[0027] The average cell size of the PPEK foam sheet can reach 21.6 μm, the cell size distribution is relatively uniform, and the cell density is large, reaching 5.20×10 6 Cells / cm 3 .

Embodiment 2

[0029] (1) Evenly add 12g of PPEK fine powder into the mold, put it into a muffle furnace to melt and plasticize for 60min, and then mold a 2mm PPEK sheet on a flat vulcanizing machine;

[0030] (2) Put the sheet obtained in step (1) into an autoclave, and pass through supercritical CO 2 Perform saturation, the saturation pressure is 25MPa, the saturation temperature is 50°C, and a saturated PPEK sheet is obtained after 60 minutes;

[0031] (3) Put the sheet obtained in step (2) into an oil bath at a temperature of 265°C and foam for 60 seconds to obtain a PPEK foam sheet.

[0032] The density of the PPEK foam sheet prepared above is 0.835g / cm 3 , the average cell size can reach 10.3μm, and the cell density can reach 8.12×10 7 Cells / cm 3 .

Embodiment 3

[0034] (1) Evenly add 12g of PPEK fine powder into the mold, put it into a muffle furnace to melt and plasticize for 60min, and then mold a 2mm PPEK sheet on a flat vulcanizing machine;

[0035] (2) Put the sheet obtained in step (1) into an autoclave, and pass through supercritical CO 2 Carry out saturation, the saturation pressure is 30MPa, the saturation temperature is 50°C, and the saturated PPEK sheet is obtained in 70 minutes;

[0036] (3) Put the sheet obtained in step (2) into an oil bath at a temperature of 270°C and foam for 90 seconds to obtain a PPEK foam sheet.

[0037] The density of the PPEK foam sheet prepared above is 0.801g / cm 3 , the average cell size can reach 8.5μm, and the cell density can reach 3.87×10 7 Cells / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com