Dispersion method of suspension bed hydrogenation water-soluble catalyst

A catalyst, water-soluble technology, applied in the petroleum industry, treatment with moving solid particles, control/regulation of hydrocarbon oil treatment, etc., can solve the problems of high water content of catalyst raw materials and difficult dispersion, and achieve lower water content and better dispersion effect. , the effect of simple foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

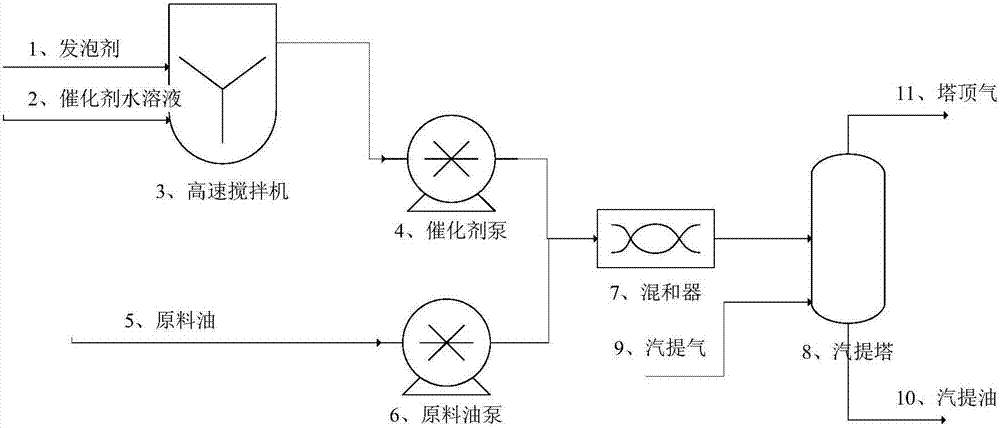

Method used

Image

Examples

Embodiment 1

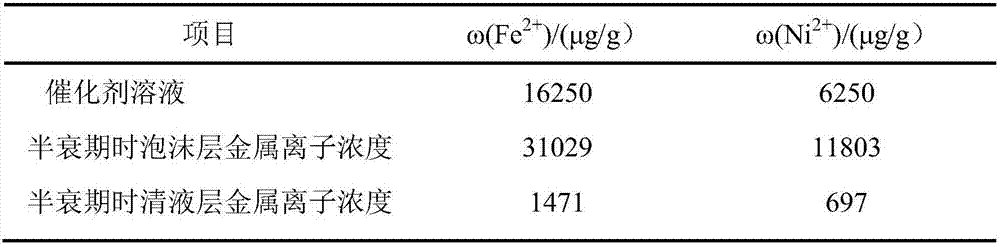

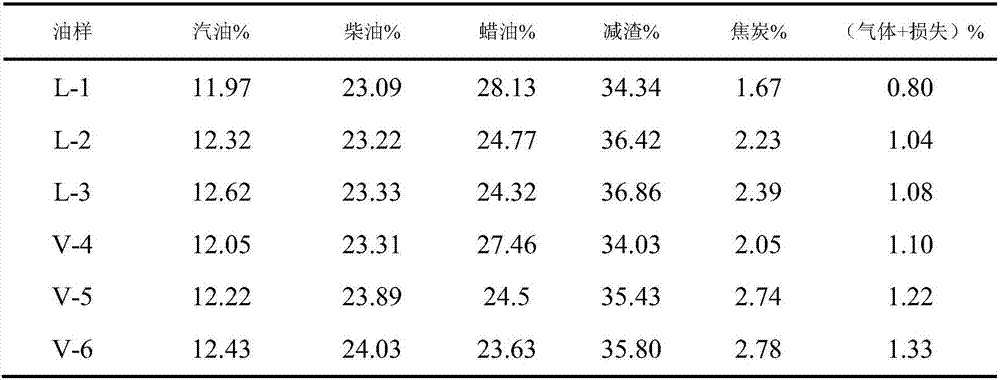

[0030] At 16250μg / g FeSO 4 and 6250 μg / g NiSO 4 Add sodium dodecylbenzenesulfonate / Tween 80 addition amount to the foaming agent combination of 5g / L in the prepared composite catalyst aqueous solution, under the condition that the rotating speed is 5000r / min and the stirring temperature is 25°C, After stirring for 60 seconds, it is divided into upper and lower layers. The upper layer is a catalyst dispersion system in a stable foam state, and the lower layer is a clear liquid; the metal ion concentration of the foam layer (upper layer) and the clear liquid layer (lower layer) is carried out by atomic absorption spectroscopy during the half-life of the microfoam. Analysis, the results are shown in Table 1, and Table 2 is the main product yield of the suspended bed hydrogenation reaction after the catalyst is dispersed in Liaohe normal slag and Venezuelan normal slag in different ways.

[0031] Table 1 Concentration of metal ions in different systems measured by atomic absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com