Dispersion method of suspension bed hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, applied in the direction of hydrocarbon oil treatment control/regulation, treatment with moving solid particles, etc., can solve the large burden of steam stripping and demulsification, poor performance, easy aggregation and dispersing effect of larger droplets, etc. problem, to achieve the effect of good dispersion and simple foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

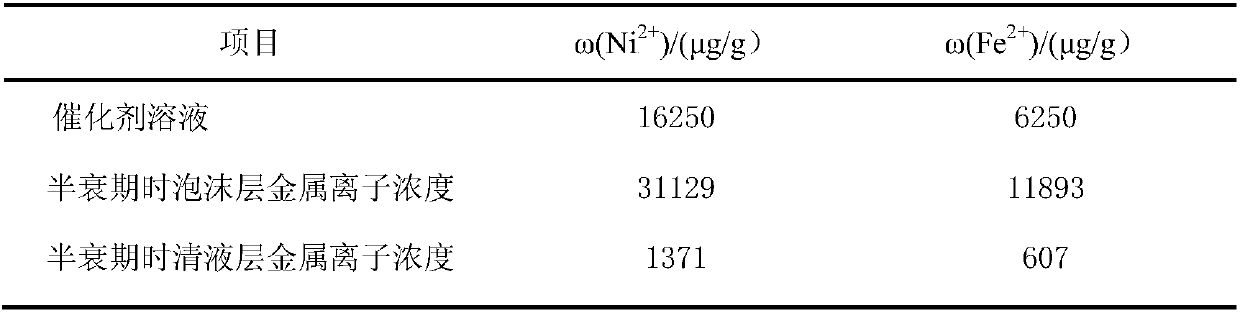

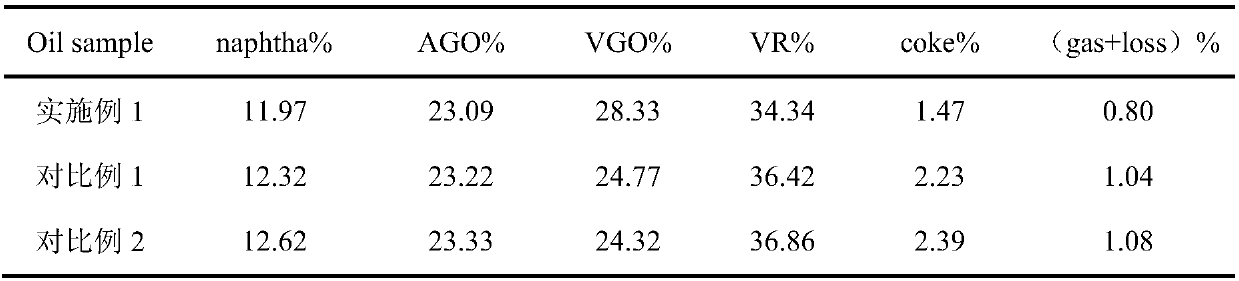

Embodiment 1

[0028] The suspended bed hydrogenation catalyst is composed of a water-soluble catalyst nickel sulfate solution and an oil-soluble catalyst iron naphthenate, the weight ratio of the water-soluble catalyst and the oil-soluble catalyst is 9:1, and the water-soluble catalyst is added into the water-soluble catalyst solution. Solution 2wt% foaming agent SDS, to obtain mixed solution A; Mixed solution A is placed under a high-speed mixer and stirred to make the foam rich, the speed of the high-speed mixer is 5000r / min, and the stirring time is 600 seconds to obtain a foam system; The soluble catalyst iron naphthenate is dissolved in 1wt% CTAB solution to obtain a mixed solution B. In the mixed solution B, the concentration of iron naphthenate is 5 wt%; the mixed solution B is added dropwise to the foam system to make it account for both 10% of the total volume, continue stirring after the dropwise addition to obtain a colloidal liquid foam. The colloidal liquid foam is added to the...

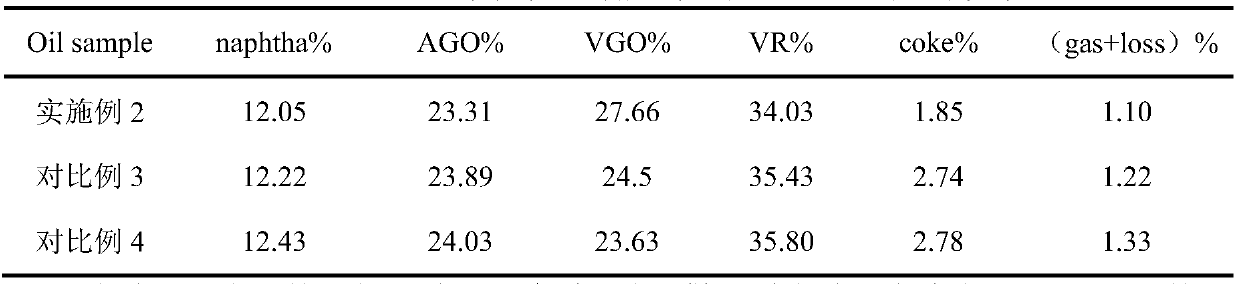

Embodiment 2

[0030] The suspended bed hydrogenation catalyst is composed of a water-soluble catalyst nickel sulfate solution and an oil-soluble catalyst molybdenum naphthenate. The weight ratio of the water-soluble catalyst to the oil-soluble catalyst is 4:1. The foaming agent SDBS of solution 1wt% is obtained mixed solution A; Mixed solution A is placed under the stirring of high-speed mixer, makes foam abundant, and rotating speed is 6000r / min, and stirring time is 700 seconds, obtains foam system; Oil-soluble catalyst ring Molybdenum alkanoate is dissolved in the Tween 80 solution of 1.5wt%, obtains mixed solution B, and in mixed solution B, the concentration of molybdenum naphthenate is 7.5wt%; In foam system, drop mixed solution B, make it account for two 20% of the total volume, continue to stir after the dropwise addition, to obtain a colloidal liquid foam. The colloidal liquid foam is added to the heavy oil raw material Venezuelan slag and stirred, and the resulting mixture enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com