Preparation of low-salt and low-viscosity polyacrylamide water-in-water dispersion by seed swelling method

A polyacrylamide and dispersion technology, which is applied in the field of water-soluble polymer dispersion synthesis, can solve the problems of high viscosity of water-in-water dispersion, unfavorable practical application, and increased system viscosity, so as to expand the scope of use and conditions of use , The degree of solution polymerization is low, and the effect of reducing the amount of inorganic salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example A1

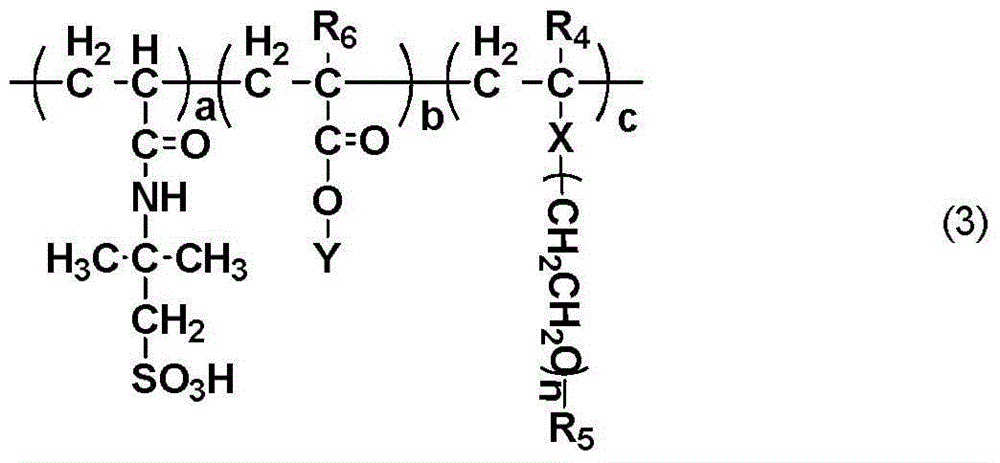

[0048] Synthesis Example A1 (Synthesis of Seed Polymer SP1)

[0049] In a glass reactor equipped with a thermometer, stirrer, nitrogen inlet tube and reflux condenser, add 15 g of (A-1), 7.5 g of (B-1), 2.5 g of (C-1) and 475 g of deionized water, while stirring, purging the reaction vessel with nitrogen, and raising the temperature to 47°C, then adding 7.5 mg of (I-1), keeping the reaction for 26 hours and then cooling to room temperature to obtain the seed polymer SP1.

Synthetic example A2-A12

[0050] Synthesis Examples A2-A12 (Synthesis of Seed Polymers SP1-SP12)

[0051] Prepare SP1-SP12 of the present invention according to the steps of Synthesis Example A1, and feed according to the ratio described in Table 2.

[0052] Table 2 The feed ratio and molecular weight of seed polymer SP

[0053]

Synthetic example B1

[0054] Synthesis Example B1 (Synthesis of Dispersion Stabilizer Stb1)

[0055] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, a nitrogen inlet tube and a reflux condenser, add 100 milliliters of deionized water, purging the reaction vessel with nitrogen while stirring, and raising the temperature to 75 ° C, and then 30 grams (F-4) and 7 grams (F-1) and 5 grams (C-1) and 80 ml of deionized water to make a mixed monomer aqueous solution, drop it into the reactor, and the dropping time is 2 hours , and dropwise 20 grams of 10% ammonium persulfate initiator solution simultaneously, the time of dropping is 5 hours, after dropwise, insulation reaction is cooled to room temperature for 5 hours, obtains dispersant Stb1, and its molecular weight is 15000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com