Synthetic method of boceprevir intermediate

A synthesis method and compound technology, applied in the field of synthesis of boceprevir intermediates, can solve the problems of increasing production cost and post-processing cost, affecting product yield and production efficiency, long reaction time, etc., achieving low production cost, The effect of less reaction steps and simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

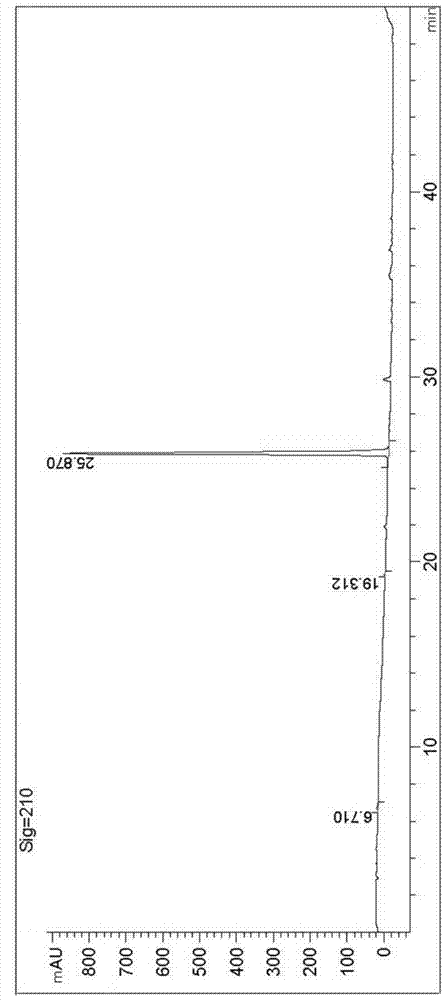

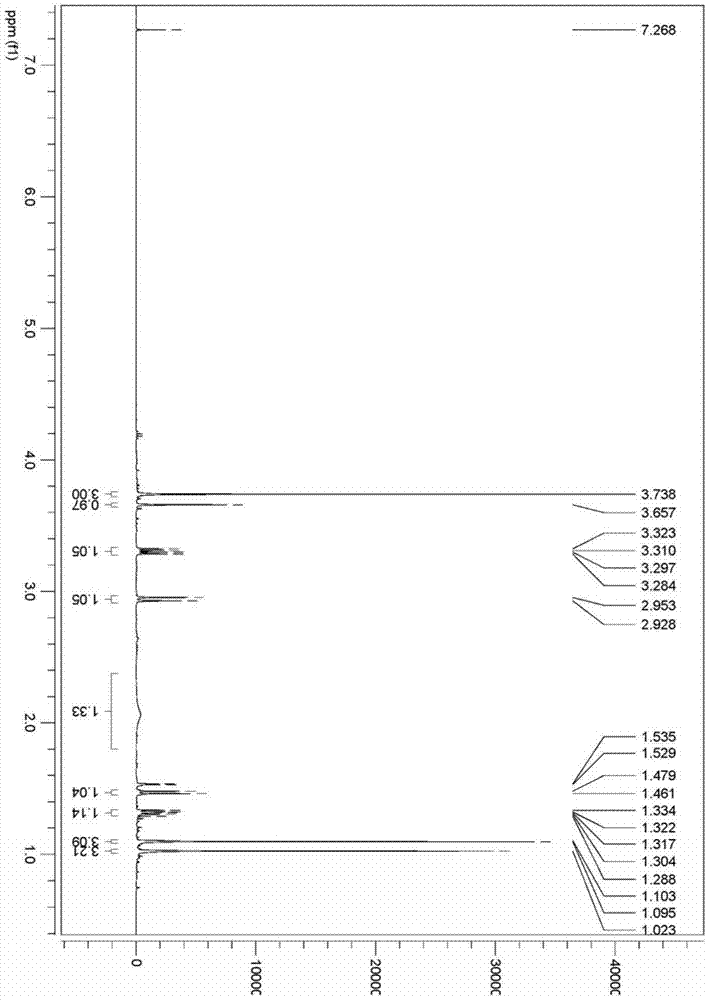

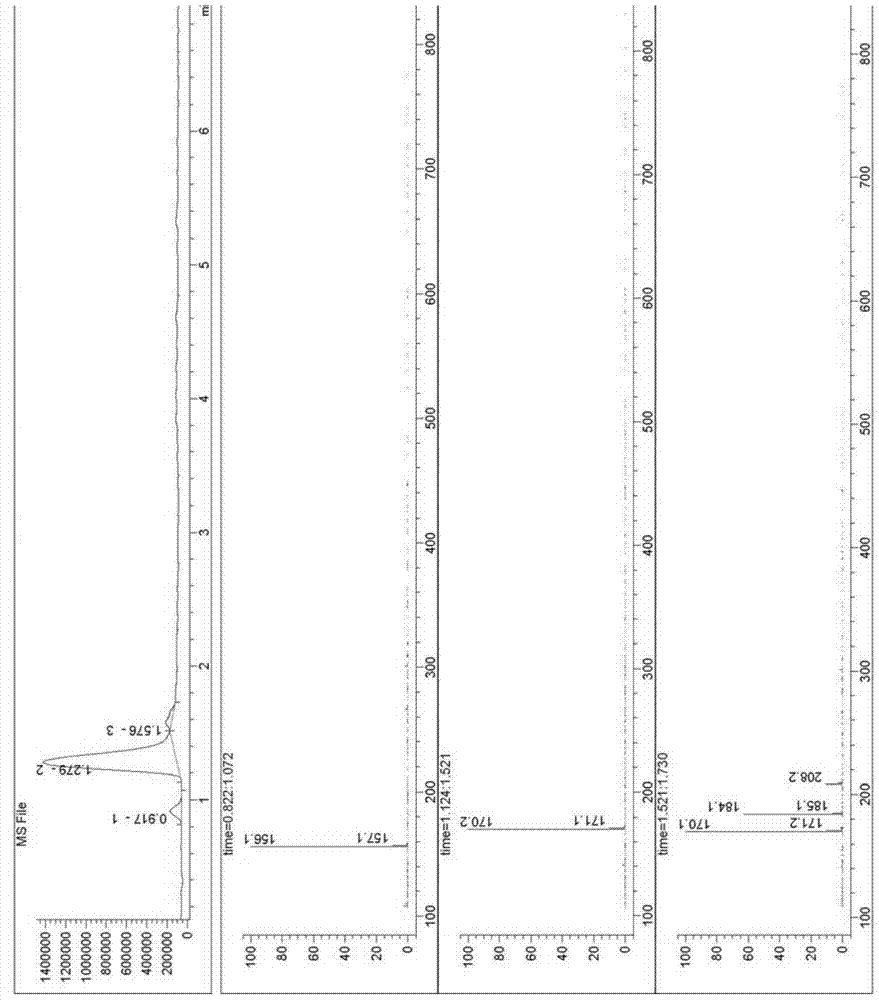

Embodiment 1

[0051] Add 300g of 6,6-dimethyl-3-azabicyclo[3.1.0]hexane hydrochloride into a 1L reaction flask and dissolve it in 200mL of methyl tert-butyl ether to form a reaction solution. Stir to dissolve and ice The salt bath was cooled to 5°C, and then 200 mL of water and 60 g of potassium carbonate were added. 112 g of di-tert-butyl dicarbonate dissolved in 150 mL of methyl tert-butyl ether was added to the reaction liquid, and the reaction was incubated at 20° C. for 3 hours until the reaction was complete. The reaction solution after the complete reaction was left to stand for liquid separation, and the organic phase was washed once with 300mL aqueous solution containing 15g of sodium bisulfate, left for liquid separation, and the organic phase was washed once with 300mL of water, and left for liquid separation again, and the organic phase was washed with 200g of sodium bisulfate Dry over sodium sulfate for 2 hours, concentrate methyl tert-butyl ether to dryness under vacuum at 40°...

Embodiment 2

[0055]Add 300g of 6,6-dimethyl-3-azabicyclo[3.1.0]hexane hydrochloride into a 1L reaction flask and dissolve it in 200mL of ethyl acetate to form a reaction solution. Stir to dissolve and cool down in an ice-salt bath to 0°C, then 200 mL of water and 46 g of potassium carbonate were added. 112 g of di-tert-butyl dicarbonate dissolved in 150 mL of ethyl acetate was added to the reaction liquid, and the reaction was incubated at 10° C. for 3 hours until the reaction was complete. The reaction solution after the complete reaction was left to stand for liquid separation, and the organic phase was washed once with 300mL aqueous solution containing 15g of sodium bisulfate, left for liquid separation, and the organic phase was washed once with 300mL of water, and left for liquid separation again, and the organic phase was washed with 200g of sodium bisulfate Dry over sodium sulfate for 2 hours, concentrate ethyl acetate to dryness under vacuum at 35°C, add 200 mL of n-heptane and con...

Embodiment 3

[0059] Add 300g of 6,6-dimethyl-3-azabicyclo[3.1.0]hexane hydrochloride into a 1L reaction flask and dissolve it in 200mL of dichloromethane to form a reaction solution. Stir to dissolve and cool down in an ice-salt bath to 0°C, then 200 mL of water and 36.6 g of potassium carbonate were added. 112 g of di-tert-butyl dicarbonate dissolved in 150 mL of dichloromethane was added to the reaction liquid, and the reaction was maintained at 10° C. for 3 hours until the reaction was complete. The reaction solution after the complete reaction was left to stand for liquid separation, and the organic phase was washed once with 300mL aqueous solution containing 15g of sodium bisulfate, left for liquid separation, and the organic phase was washed once with 300mL of water, and left for liquid separation again, and the organic phase was washed with 200g of sodium bisulfate Dry over sodium sulfate for 2 hours, concentrate dichloromethane to dryness under vacuum at 35°C, add 200 mL of n-hepta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com