A locking mechanism for a movable mold on a die-casting machine or an injection molding machine

A locking mechanism and injection molding machine technology, applied in the field of injection molding or die-casting, can solve the problems of limiting the scope of application of die-casting machines and injection molding machines, deformation of the clamping surfaces of moving plates and fixed plates, and difficulty in guaranteeing product quality, so as to improve the casting function. and application range, reduce the driving force, improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

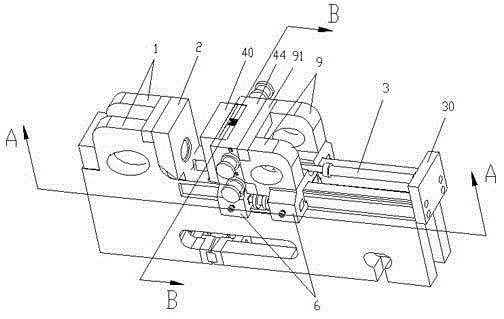

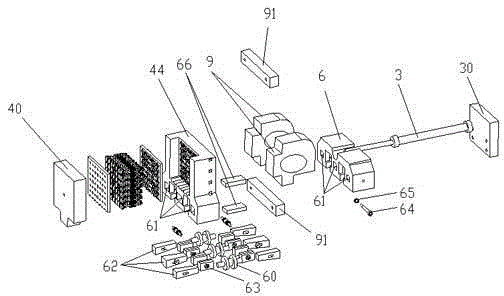

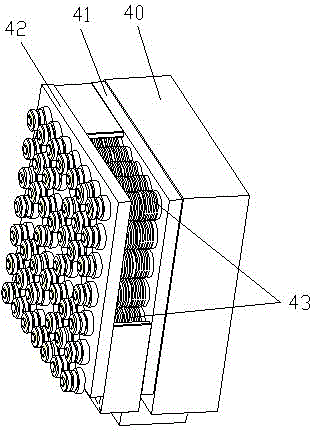

[0034] see Figure 1-2The locking mechanism of the movable mold on the die casting machine or injection molding machine of the present invention has a driving mechanism 3 that pushes the movable template 40 to move closer to or away from the fixed template 2 along the track 11 on the frame 1, and the movable The template 40 is installed on the sliding seat 44 , the ejecting end of the driving mechanism 3 is connected with the sliding seat 44 , and the driving mechanism 3 is fixed on the end of the frame 1 away from the fixed template 2 through the support 30 . The mold locking device 6 is provided below the sliding seat 44, and the mold locking device 6 and the sliding seat 44 are fixedly connected or integrally formed. And molded on the locking cavity 61 on the sliding seat 44, and the locking wedge 63 and the pushing wedge 62 located inside the locking cavity 61, the locking wedge 63 is close to the side wall of the track 11 Set, the pushing wedge 62 is located between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com