Simple flyer sticking and clamping special device and usage thereof

A special device and flying piece technology, which is applied in the field of positioning and clamping special device for flying pieces in laser-driven flying piece micro-forming, can solve problems such as low working efficiency, reduced impact forming effect, and flyer wrinkling, etc., to achieve Improve the accuracy of pasting position, ensure the same pasting, and improve the formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

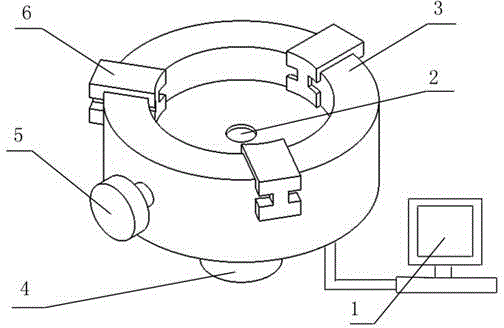

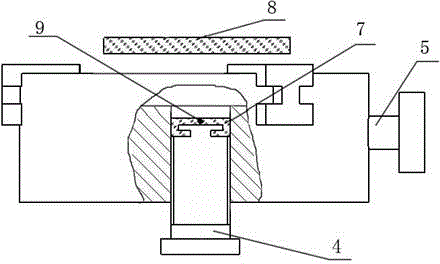

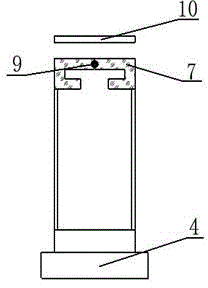

[0023] The details and working conditions of a simple special device for sticking and clamping flyers of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The structure of a simple flying piece sticking and clamping special device of the present invention is as follows: figure 1 As shown, its working principle is as follows figure 2 As shown, the device is set on a glass tank 3 for placing K9 glass, and a flyer tank 2 with a through-hole structure is arranged in the middle of the glass tank 3 . The device consists of K9 glass fixing system, flyer clamping and positioning system and pressure testing system.

[0025] The K9 glass fixing system includes at least three positioning blocks 6 arranged on the edge of the glass tank 3 (the present invention is only described in the case of three positioning blocks 6 ) and arranged on the outer wall of the glass tank 3 for adjusting the positioning blocks 6 to shrink Or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com