Tool electrode assembly and grinding wheel repair machine

A tool electrode and repairing machine technology, which is applied in the field of grinding wheel repairing machines, can solve the problem of unrepairable waste grinding wheels, etc., and achieves the effects of improving repairing effect, reducing manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

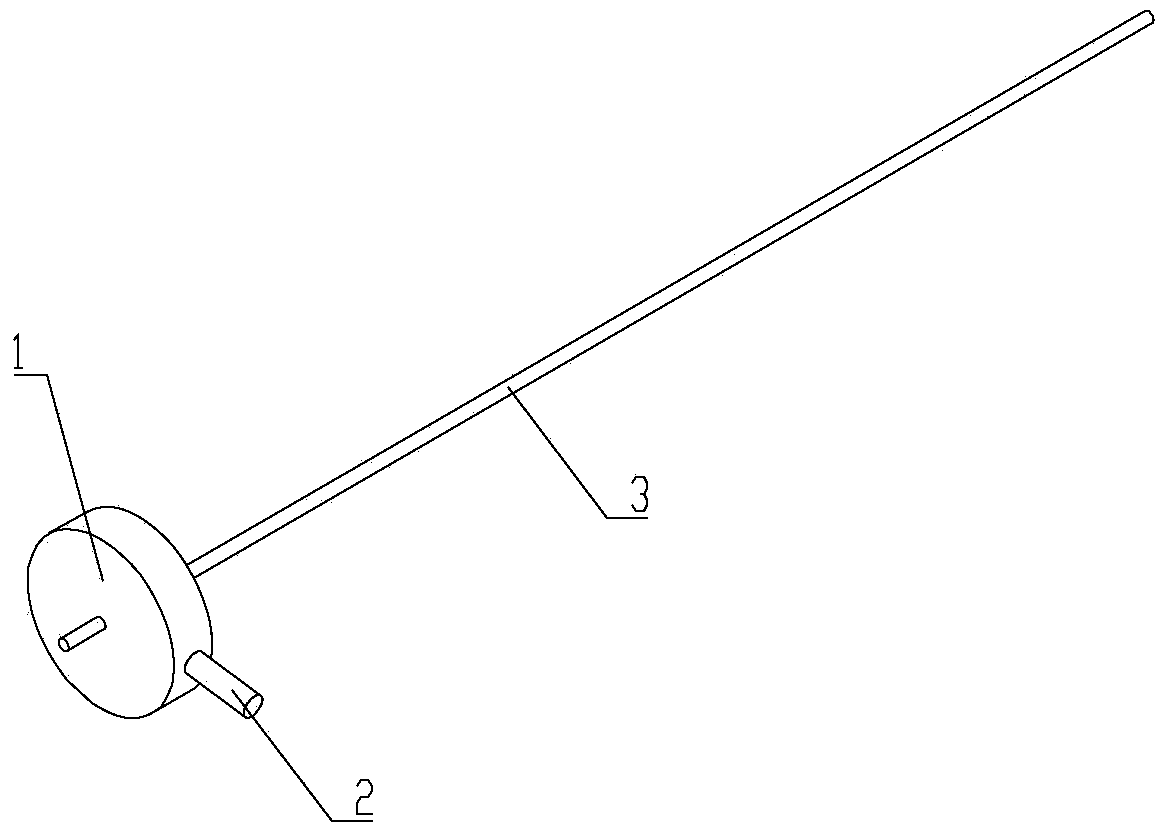

[0029] Embodiment 1 Tool electrode assembly

[0030] Such as figure 1 As shown, the tool electrode assembly of the present invention includes a fixing element 1, a screw 2 and a cylindrical tool electrode 3, the fixing element 1 is cylindrical, and a through hole is provided at the axis of the fixing element 1, and the through hole The inner diameter of the hole corresponds to the outer diameter of the tool electrode 3, and the fixed element 1 is also provided with a threaded hole perpendicular to the axis line of the through hole, the threaded hole communicates with the through hole, and the threaded hole is connected with the screw 2 The screw fit is used to fasten the tool electrode 3 inserted into the through hole. When in use, one end of the tool electrode 3 is inserted into the through hole of the fixing element 1, and then the screw 2 is screwed into the threaded hole, so that the screw 2 withstands the tool electrode 3 to fix it. In addition, the screw 2 is tightly A...

Embodiment 2

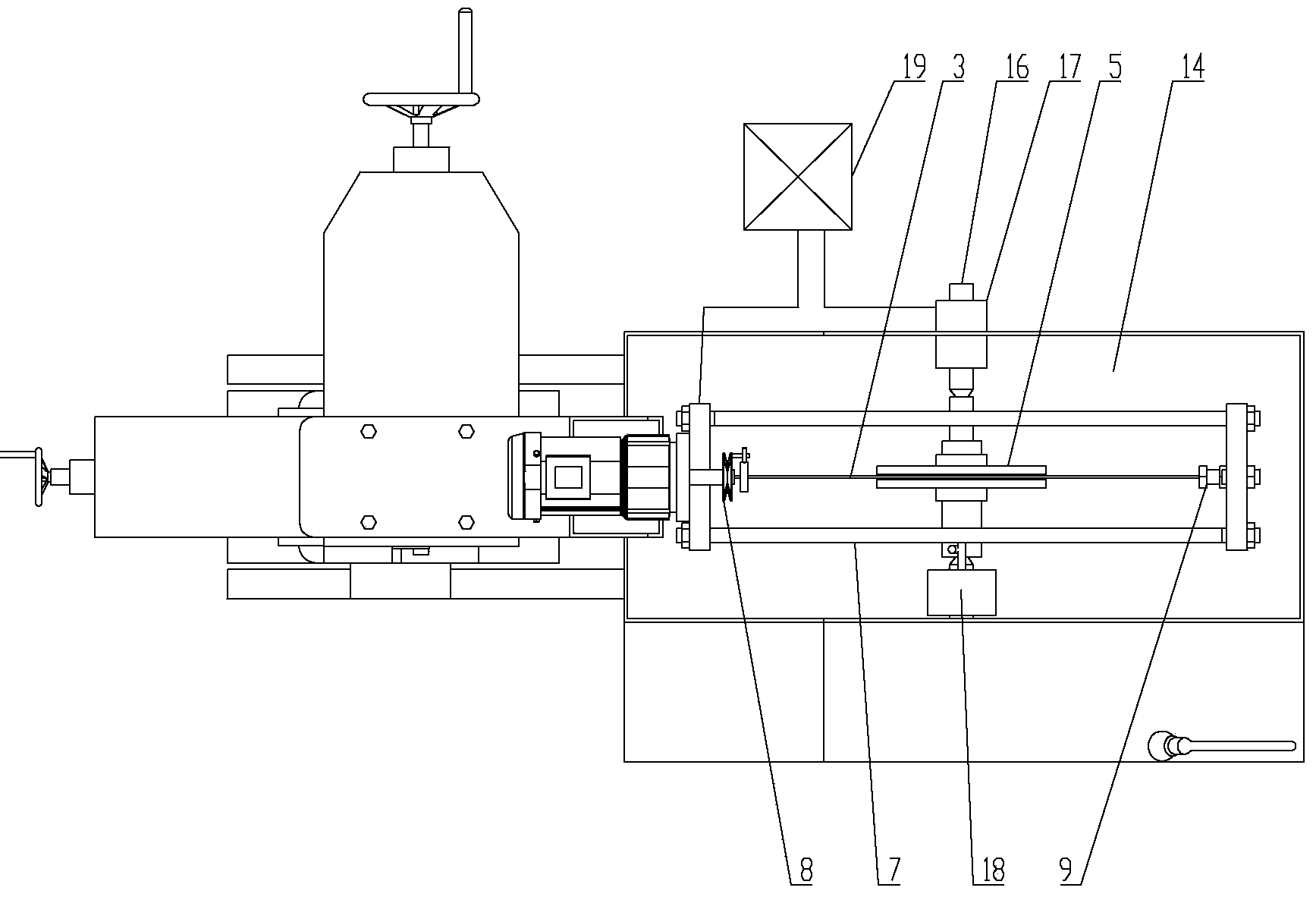

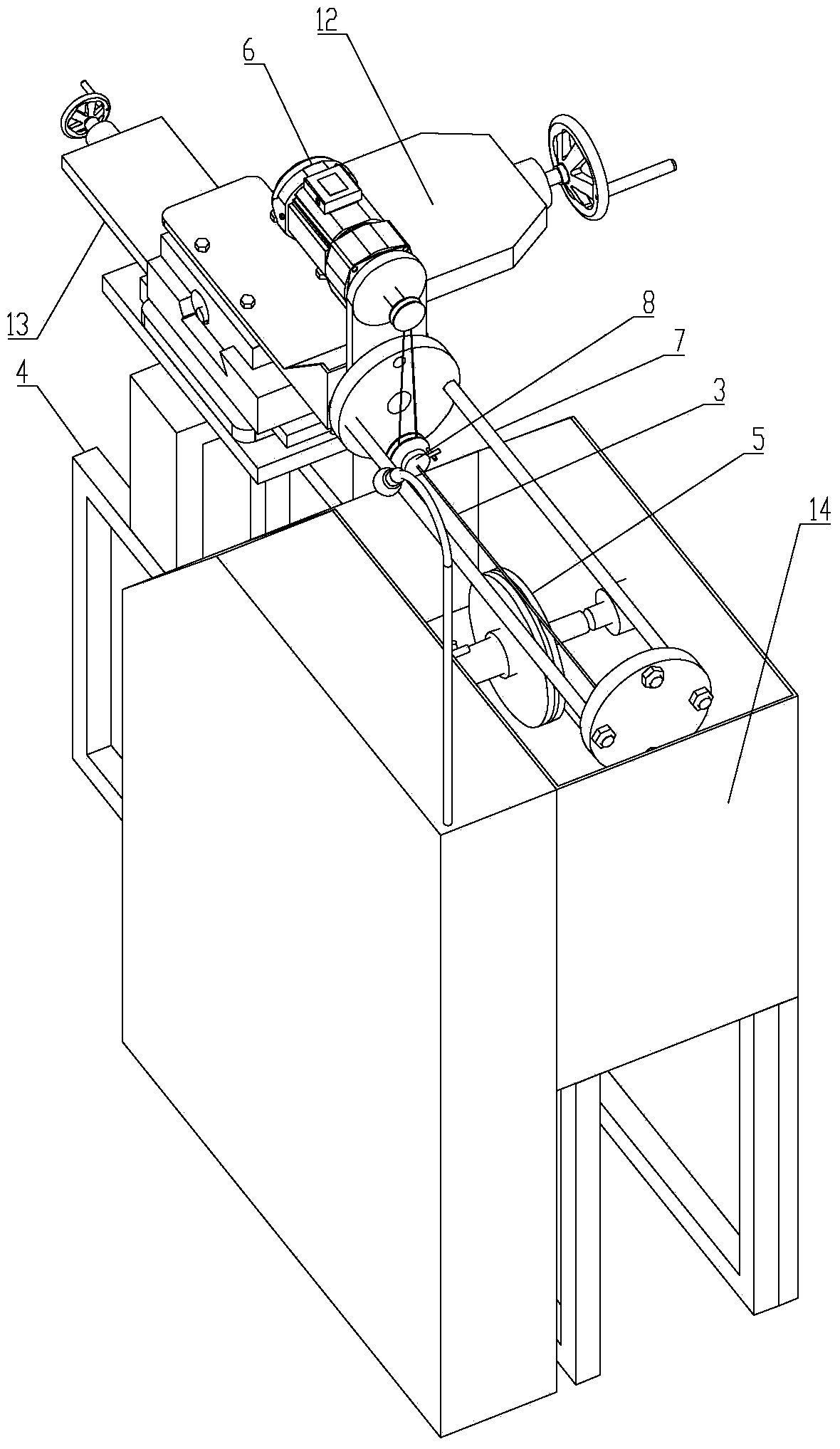

[0031] Embodiment 2 grinding wheel repairing machine

[0032] Such as Figures 2 to 9 As shown, the grinding wheel repairing machine of the present invention includes a frame 4, a feed adjustment device arranged on the frame 4 for controlling the relative movement between the tool electrode 3 and the grinding wheel workpiece 5, for clamping the tool electrode 3 and The clamping device of the grinding wheel workpiece 5 and the driving device for driving the tool electrode 3 and the grinding wheel workpiece 5 to rotate, also includes a pulse power supply 19, the anode of the pulse power supply 19 is connected to the tool electrode 3, and the cathode of the pulse power supply is connected to the grinding wheel workpiece 5; the driving device includes a motor A6 that drives the tool electrode 3 to rotate, and the clamping device includes a tool electrode 3 clamping device and a grinding wheel workpiece 5 clamping device, and the tool electrode 3 clamping device includes a cantilev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com