Ladle casting combined drainage device and method of manufacture and use

A ladle and drainage sand technology, which is applied to casting equipment, manufacturing tools, casting molten material containers, etc., can solve the problems of inconvenient production and use, complex structure of sand storage device, and high material consumption of shell, etc., to achieve novel conception, The effect of tight combination and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

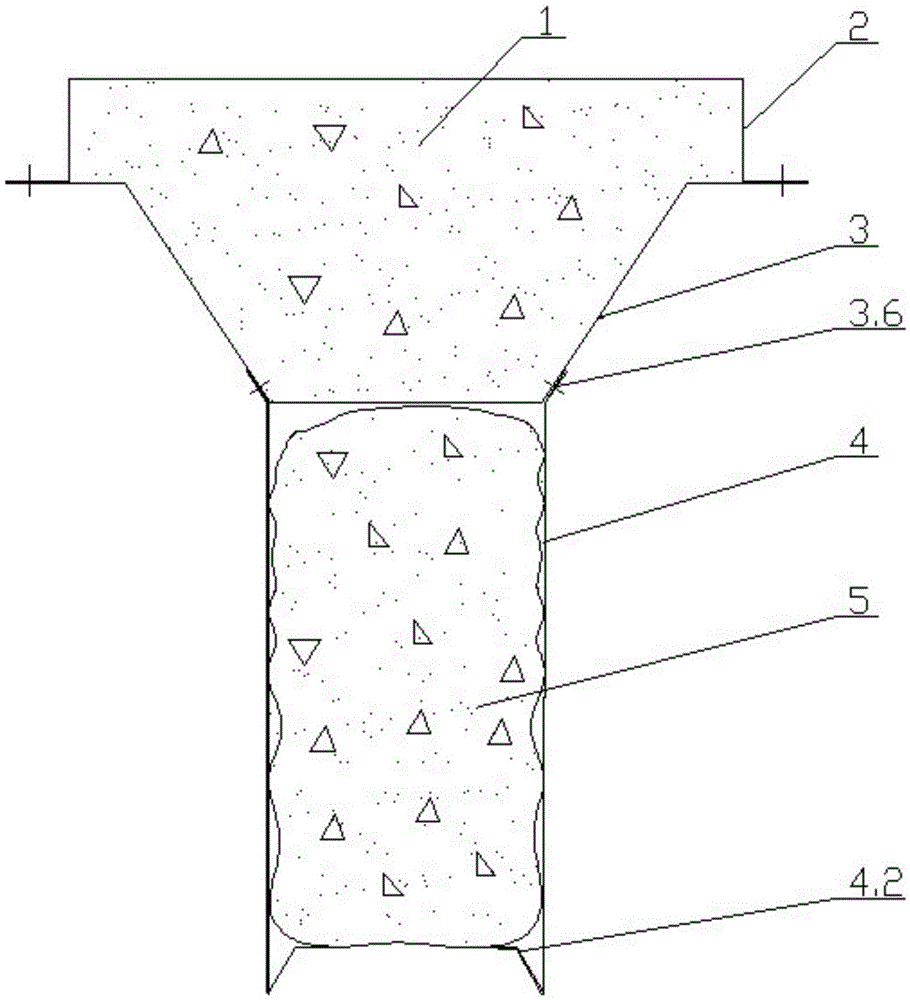

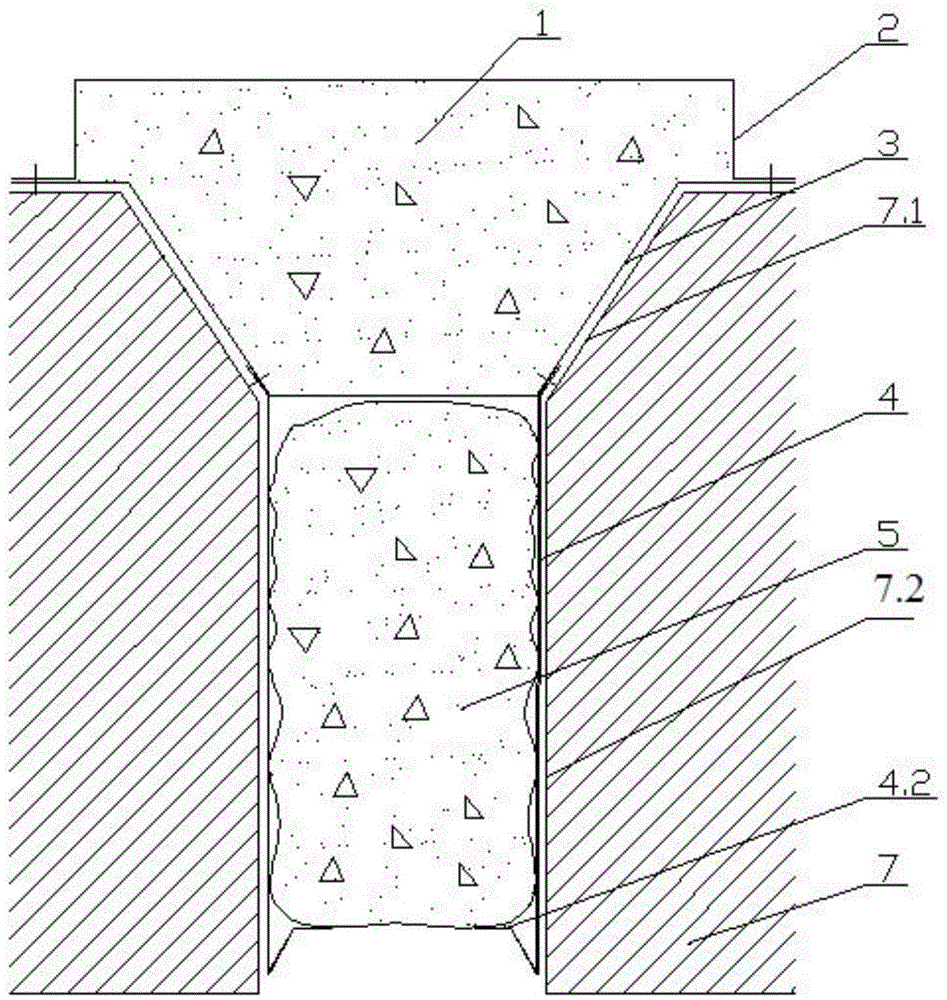

[0052] Depend on figure 1 , figure 2 It can be seen that the ladle casting combined drainage device is composed of a guide rod, a traction rope (not marked in the figure) and a drainage plug. The drainage plug is composed of the upper sand cylinder 2 and the lower sand cylinder 3, the fastening slats 4 and the lower drainage sand bag 5. The upper sand cylinder is a circular cylinder with a flat edge, and the diameter is larger than the upper mouth of the nozzle Diameter; the lower sand cylinder is a conical basin with flat sides, the diameter of the upper opening is equivalent to the inner diameter of the upper mouth of the nozzle, and the lower sand cylinder is consistent with the inner wall of the conical bucket of the nozzle; the diameter of the flat edge of the lower sand cylinder is the same as that of the upper sand cylinder. The outer diameters of the flat sides are equal, both of which are larger than the upper diameter of the nozzle. The upper sand cylinder is fixed...

Embodiment 2

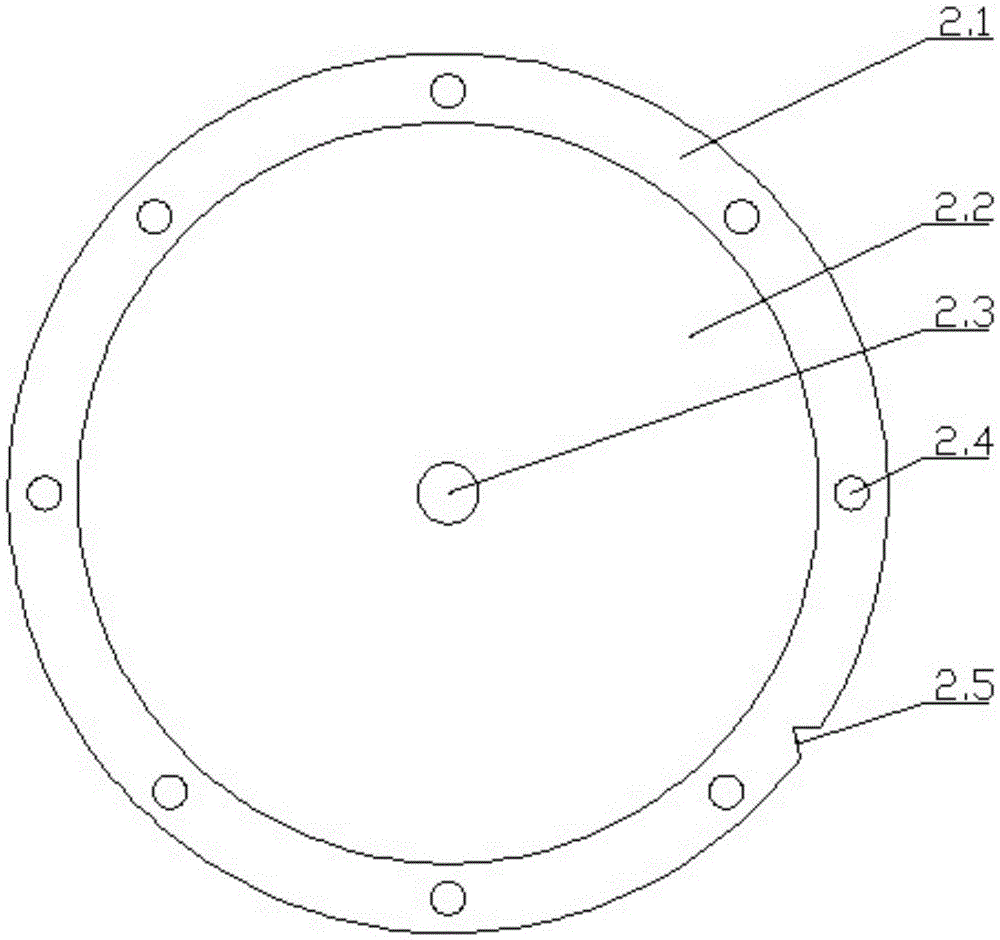

[0058] Depend on Figure 6 It can be seen that the center of the bottom 2.2 of the upper sand cylinder 2 is provided with a guide hole 2.3, the upper flat side 2.1 is provided with a through hole 2.4 and a gap 2.5, and the center of the lower sand cylinder 3 basin bottom 3.2 is correspondingly provided with a guide hole 3.3 and a lower flat side 3.1 Correspondingly, a lower through hole 3.4 and a lower notch 3.5 are arranged on the upper part, and a through hole (no serial number is marked) is arranged on the upper and lower sand cylinder walls. Drainage sand is placed in the soft metal mesh bag 6 that does not leak sand, and the metal mesh bag is placed in the synthetic cylinder of upper sand cylinder and lower sand cylinder. The weight of the cylinder is reduced, which is convenient for conveying; after the molten steel enters the ladle, the upper sand cylinder, the lower sand cylinder and the metal mesh bag are melted quickly, and the drainage sand is filled in the nozzle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com