Production method of oxygen-free copper pipe for electric vacuum component

A technology of oxygen-free copper tube and production method, which is applied in the field of non-ferrous metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

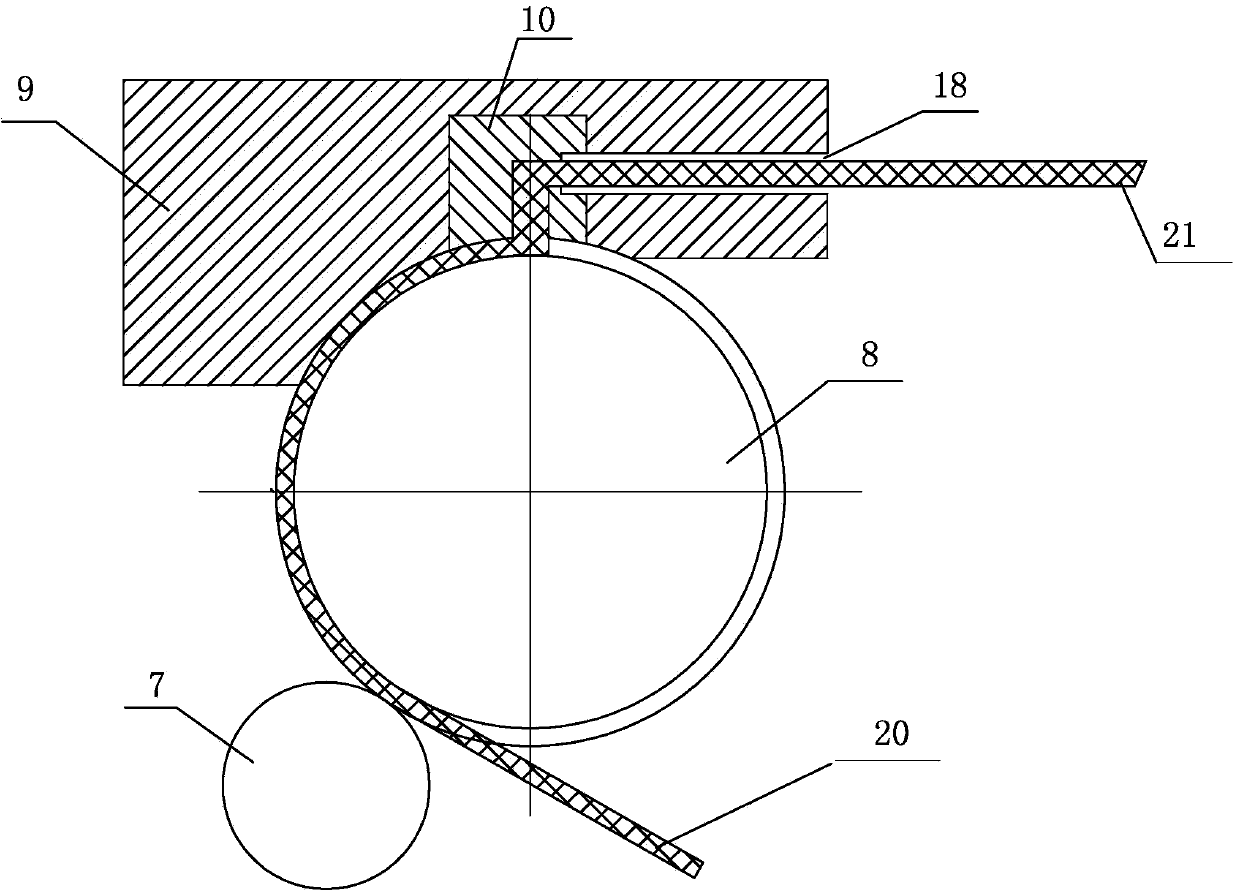

[0024] 2) Expanded welding and forming: the oxygen-free copper rod 20 obtained in the above step 1) is welded with an expanded welding and forming device, which includes a compacting wheel 7, an extrusion wheel 8 and a shoe seat 9; Wherein said compacting wheel 7 is engaged with extrusion wheel 8 and installed; said extrusion wheel 8 is fixedly connected with shoe seat 9; said shoe seat 9 is equipped with working body 10; said working body 10 A choke ring 11, an expansion welder 12, a flow-promoting ring 13, a sizing ring 14 and a mold 15 are installed in sequence; a feed port 16 and a discharge port 17 are provided in the working body; the feed port 16 is connected with the expansion welder 12; the mold 15 is connected with the discharge port 17; side; the boot seat 9 is provided with a copper pipe outlet 18; the copper pipe outlet 18 is connected to the discharge port 17; the extrusion wheel 8 is a single wheel double groove structure; the Ф20mm anaerobic After the copper r...

Embodiment 2

[0035] 2) Expanded welding and forming: the oxygen-free copper rod obtained in the step 1) is welded with an expanded welding and forming device, and the expansion welding and forming device includes a compacting wheel 7, an extrusion wheel 8 and a shoe seat 9; The compacting wheel 7 is engaged and installed with the extrusion wheel 8; the extrusion wheel 8 is fixedly connected with the shoe seat 9; the working body 10 is installed in the shoe seat 9; the working body 10 is sequentially A choke ring 11, an expansion welder 12, a flow-promoting ring 13, a sizing ring 14 and a mold 15 are installed; a feed port 16 and a discharge port 17 are provided in the working body; the feed port 16 It is connected with the expansion welding device 12; the mold 15 is connected with the discharge port 17; ; There is a copper pipe outlet 18 in the boot seat 9; the copper pipe outlet 18 is connected to the discharge port 17; the extrusion wheel 8 is a single wheel double groove structure; the ...

Embodiment 3

[0045] 2) Expanded welding and forming: the oxygen-free copper rod obtained in the step 1) is welded with an expanded welding and forming device, and the expansion welding and forming device includes a compacting wheel 7, an extrusion wheel 8 and a shoe seat 9; The compacting wheel 7 is engaged and installed with the extrusion wheel 8; the extrusion wheel 8 is fixedly connected with the shoe seat 9; the working body 10 is installed in the shoe seat 9; the working body 10 is sequentially A choke ring 11, an expansion welder 12, a flow-promoting ring 13, a sizing ring 14 and a mold 15 are installed; a feed port 16 and a discharge port 17 are provided in the working body; the feed port 16 It is connected with the expansion welding device 12; the mold 15 is connected with the discharge port 17; ; There is a copper pipe outlet 18 in the boot seat 9; the copper pipe outlet 18 is connected to the discharge port 17; the extrusion wheel 8 is a single-wheel double-groove structure; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com